Central Bursts, Chevroning in Cold-Drawn and Extruded Steels

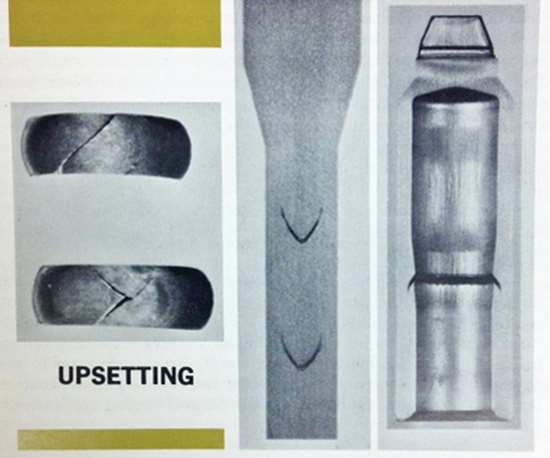

The compressive stresses of cold working can result in failures by shear along planes 45 degrees to the applied stress.

In cold-worked steels, failures can be broadly categorized in two categories. The first are those nucleated by localized defects, such as seams, pipe and exogenous inclusions. The second are those that result from exceeding the strength of the material itself.

The compressive stresses of cold working can result in failures by shear along planes 45 degrees to the applied stress. These are known as shear failures. The presence of shear failures in an otherwise metallurgically normal material indicates excessive mechanical deformation. While often the result of tooling issues, conditions that lower material ductility include chemistry, macrostructure, nonmetallics, microstructure and aging. Hydrogen embrittlement has also been implicated in investigations of premature shear failure.

Featured Content

This cribsheet will focus on the central bursts in the product of cold-drawn steel, especially from the point of view of a shop making parts on automated equipment.

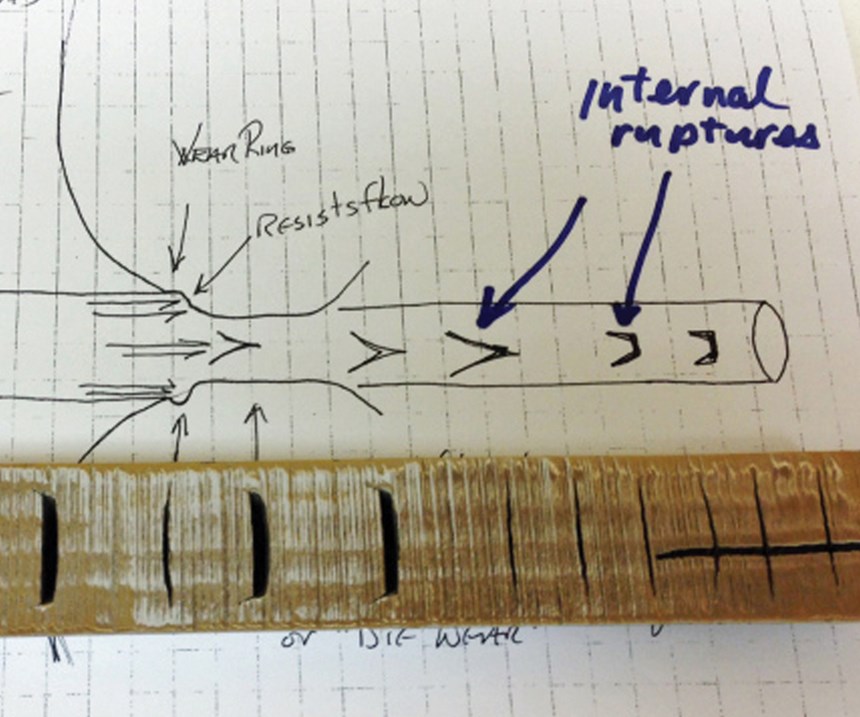

The role of tooling at the cold-drawing mill is usually considered to be the root cause, as replacement of dies typically eliminates the central bursting. Increased stresses as the result of a “wear ring” in the die are generally found to be the cause of the bursting rather than smooth fl ow of the material. Other factors involved include die angle (half angle), reduction in area, friction in process and strain hardening coefficient of the grade involved. A bar that exhibited central bursting was saw cut lengthwise to show the internal ruptures.

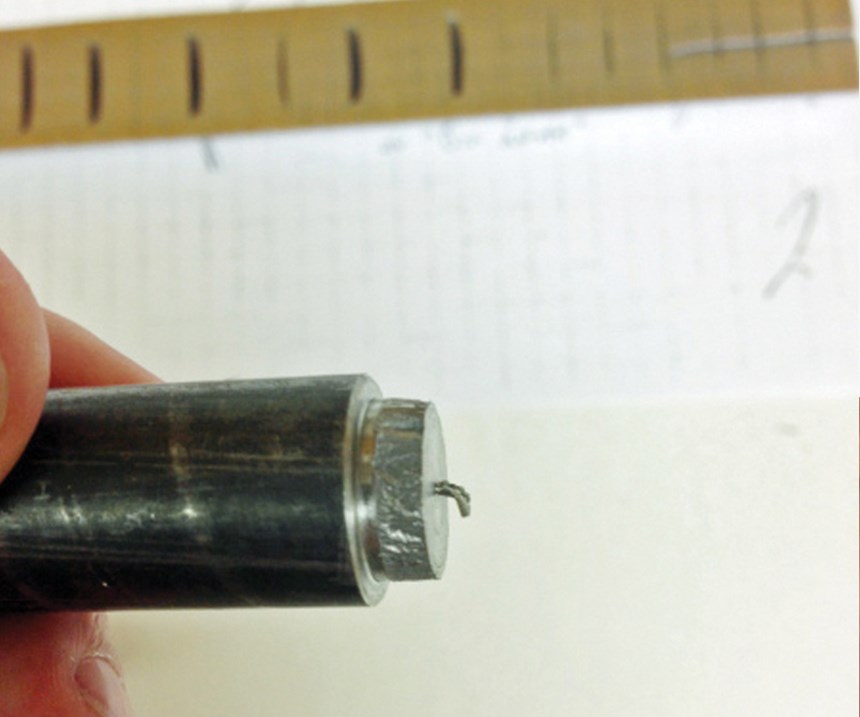

In rare cases, while machining parts from a bar that exhibits internal bursts or chevrons, the part will separate from the bar in the process because of the prior existing rupture. The photo below shows such a part. Note the fracture surface on the sides of the stepped down diameter on the part end shown in the photo below.

You might see these kinds of failures more often found in parts that are cold headed or cold extruded. Central bursts or internal chevrons are rare in the marketplace these days, as a result of improved tooling, drawing lubricants, die design and maintenance at the mills. However, if you find parts breaking off on the machine prior to being cut, you might be encountering central bursts in the steel.