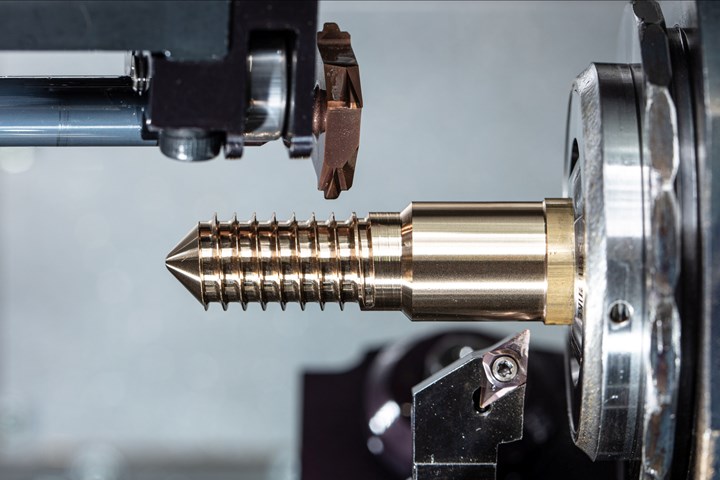

Turn-whirl milling can produce threads with a true variable pitch by dynamically changing the thread profile.(Photo Credit: Horn/Sauermann)

Last year, I traveled to Germany to attend Paul Horn’s Technology Days event at its headquarters in Tubingen, which was attended by more than 3,000 people. As part of that, I took in presentations on topics such as new High-Power Impulse Magnetron Sputtering technology (developed in conjunction with CemeCon AG) for smooth finishing/eliminating droplets on physical vapor deposition (PVD) tool coatings; challenges/solutions for machining lead-free brass and steel; the new Horn Tooling Configurator (HTC) custom tool design process; and more.

Part of the “more” was an introduction to research into applying a new mix of high-speed turn-whirl milling, polygon turning and rotational turning for medical bone screws and nails.

Featured Content

Modern medical implants for orthopedics, traumatology and dental technology are characterized by rigorous demands on strength, biocompatibility and bionic-optimized geometry. The geometry of an implant is adapted to the bone and tissue. In the process, the functional surfaces of the implants are given an increasingly sophisticated design in order to facilitate their attachment in the body and make them less invasive for the patient. The new designs of implants drive up manufacturing costs because the surfaces are no longer circular or square. They have more curved surfaces and functional elements with continuous transitions in a very small space. In particular, the need for several manufacturing steps on different machines causes costs to rise significantly. For example, precise handling for exact reclamping of a workpiece represents a considerable cost factor. Therefore, despite the high level of functional integration, an efficient process route is needed for economical production.

ZykloMed is a joint project funded by Germany’s Federal Ministry of Education and Research (BMBF) including participating partners Index, Paul Horn, Beutter Präzisions-Komponenten GmbH and the wbk Institute for Production Engineering at the Karlsruhe Institute of Technology (KIT). The project’s goal was to develop new manufacturing processes for the economical machining of medical implants with multifunctional and non-round bionic designs. The three manufacturing processes developed were eccentric turning, polygon turning and turn-whirl milling.

These three processes are all based on the same kinematic principle of multiple synchronized rotating axes. While this principle is well known, its application to non-circular and curved shapes is highly demanding. At the same time, the practical implementation must meet the high quality requirements of the medical industry.

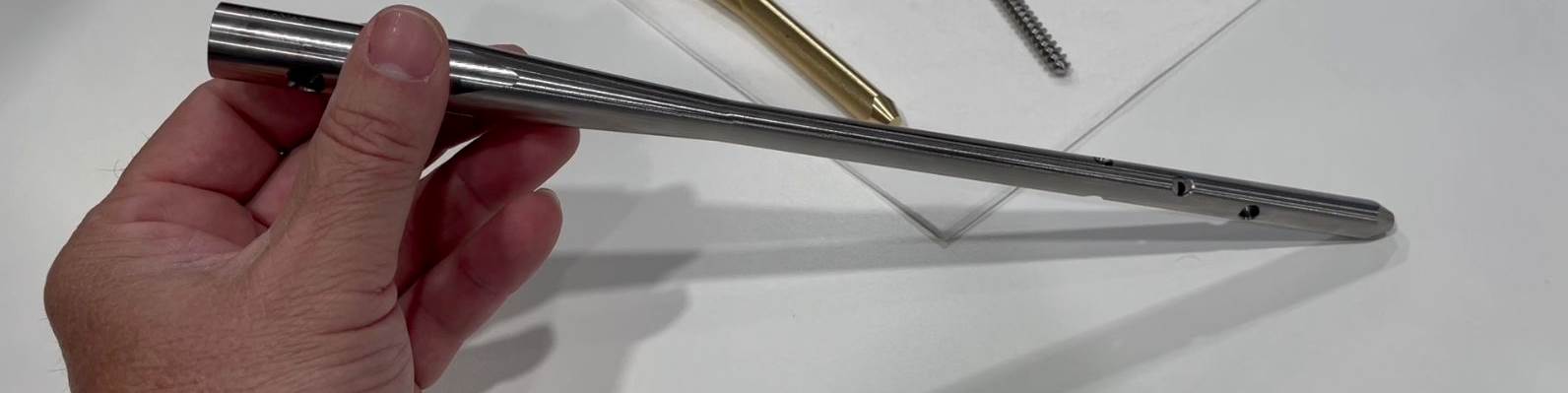

This photo of bone screw threads in brass material — with no coolant used, as would be required for titanium — was taken for demonstration purposes to show how the tool for turn-whirl milling engages with the workpiece to produce the threads. (Photo Credit: Horn)

The project partners researched and developed manufacturing procedures along the entire process and supply chain, from the machines and control technology to the tool design to prototype and pre-series production. The manufacturing processes were simulated and designed based on known methods with the same mathematical principles to determine the requirements for tool and machine. The tests were divided into equivalence tests under laboratory conditions, as well as pre-series tests in laboratory and near-application environments. The engineers focused on both machine and tool technology for the development and design of the following three processes:

Turn-whirl milling is a productive process for producing threads for bone screws. One or two circular milling cutters are set at a certain angle to the workpiece. The directions of rotation of the cutters and the workpiece can be the same or opposite. The speed ratio of the workpiece to the two cutters depends on the number of screw threads and the number of cutter inserts. The process can be used to economically produce threads with a true variable pitch by dynamically changing the thread profile.

Polygon turning is a process for producing non-circular external and internal contours with a hypotrochoid shape. Like rotary eccentric turning, the process offers the possibility of producing non-circular contours on lathes. During the process, the parallel axes of the workpiece and the tool are offset from each other by an axial distance and are brought into a specific speed ratio under positional coupling. The axial distance — the speed ratio of the workpiece to the tool and the cutting diameter of the inserts — define the dimension of the contour. A tool system for polygon turning is individually adapted to the contour of the workpiece to be produced.

Polygon turning can produce internal contours with a hypotrochoid shape such as those required for medical bone screws. (Photo Credit: Horn/Sauermann)

Eccentric turning uses a rotating, non-circular tool guided along a rotating workpiece under positional coupling. The speeds are brought into a certain ratio to each other and the out-of-round shape is thus reproduced. The process is said to offer highly productive production of eccentric outer contours, and the rotation of the tool reduces the thermal load at the cutting edge to extend tool life. The process also enables the production of tapered profiles, making it well suited for bone nails.

Eccentric turning uses a rotating, non-circular tool guided along a rotating workpiece to produce an out-of-round shape common for modern medical bone nails. (Photo Credit: PM)

With successful tests in a near-series production environment, the ZykloMed partners have come a big step closer to the goal of economic production of implants of multifunctional and non-round bionic design. The engineers proved that the synchronized manufacturing processes enable the economic production of modern implants. In addition to the production of new component geometries, the processes also offer optimization potential for the economic production of existing implants, as well as possible applications beyond the medical industry.

RELATED CONTENT

-

Inverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.

-

Generating More Efficient Milling Tool Paths for Multitasking Machines

This toolpath generator can reduce cycle time and extend tool life while helping achieve better surface finishes for milling operations on multi-axis Swiss-types and turn-mills.

-

When a “Boxy” Part is Machined on a Lathe

South Morgan Technologies has long thrived on its ability to mill prismatic parts on a turning platform. Today, newer technology and techniques enable saying “yes” to that work than ever before.