Monitoring Perishable Tools On Automatics

Monitoring tool wear is an essential component to getting greater productivity and lower costs from a machine tool.

Most new CNC machine tools today offer some kind of tool monitoring system, either as standard equipment or as an option with the control’s package. Some machines offer a way to detect broken or dull tools using the motors’ amperage to detect minute variations in current flow. There are also secondary vendor packages available for tool monitoring if the machine tool manufacturer doesn’t offer it.

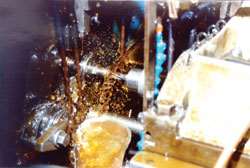

But what about tool monitoring for automatic machines such as older non-CNC screw machines, transfer lines and rotary transfer machine tools? Until recently, these machines didn’t have any way to monitor tooling, and most companies usually performed tool changes by guessing or when the tools failed (frequently causing catastrophic damage or scrapped parts).

Featured Content

One way for a company with automatic machine tools to keep track of tooling and costs is to be proactive with them. The company can produce a way to monitor tool wear using a historical reference database based on tool usage and change outs. But this leaves a lot of leeway and may not result in the most economical tool usage. If a change is done too soon, money is being wasted because tools are being re-sharpened or replaced before their life expectancy is up. Being proactive should, however, reduce catastrophic tool breakage.

If a company is reactive to tool changes, then it is probably experiencing scrapped parts because it is changing the tooling too late. This can also lead to damaged equipment and substantial downtime on each machine.

The Need

Why is it important to know when to change out a tool on an automatic machine? There are many reasons for this. By monitoring tools, you can get more parts per tool. Tool costs are lowered because you are using the tool properly and sharpening it only when needed. This will also reduce machine downtime, labor to change out the tools and grinding costs.

Rather than changing out tools randomly and disrupting production, it is done only when it is needed by using the tool monitoring system’s forecasting ability.

In addition, tool inventory can be reduced. Instead of having many duplicate tools, because you never know when the tool needs changing or will fail, you can develop your inventory around set parameters that a monitoring system offers.

You can also get faster new part process development. If you have a history of tooling from a monitoring system, then when identical or near identical parts are processed, it’s easy to see which tooling should be used on the new part for maximum productivity.

With tool monitoring, labor can be reduced, because fewer tool inspections and changes will be needed. Also, because the tools are being monitored second by second, highly skilled operators can be better used for machine setup and planning jobs. Lower skilled operators can watch the machines, because the tool monitor alerts them to tool changes, and they don’t have to guess when a change is needed.

Scrap can be significantly reduced because dull tools that produce scrap have been taken out of service before they can cause problems. Catastrophic failures will be reduced or eliminated with appropriate tool changes.

If a vendor wants you to try out new tooling, you can monitor that tool and compare it to the old one. In doing so, you’ll have a concrete comparison to see if the new tool is cost effective.

Also, when a shift change occurs, the second shift would not have to communicate with the first shift to find out what tools need to be changed. A tool monitoring system would provide the information.

With control over tooling costs and labor usage, a company can have higher overall efficiency along with improved part quality. Accurate cost estimating both for the part and tooling can also be achieved by using historical reports. This all boils down to increased profit for a company and greater overall cost control.

A New Way

Until recently, tool monitoring systems available for older non-CNC automatic machines were less effective. It didn’t make sense to upgrade older screw machines with CNC packages that offered tool monitoring to achieve the capability, either.

However, Manufacturing Consultants, Inc. (Elyria, Ohio) has developed a product called the Tool Sentinel system, a tool-monitoring system for these types of machines. The system has been in development for 7 years and has been used at beta sites for 3 1/2 years.

The system is a software- and hardware-based tool-monitoring system that is easily and quickly installed with no loss of production. It is Windows-based (it operates using either Windows 98, 2000 or NT) and can be configured to handle up to 32 automatic machines. A standard personal computer (PC) is used to run the system, but for the shopfloor environment, an industrial PC is recommended with a NEMA IV enclosure. The system comes as a package with both hardware and software installed. The package uses custom computer plug-in boards configured for the machine interface.

By using a company’s internal network, the Tool Sentinel system can be monitored anywhere, either on the floor or in an office. This allows a supervisor or manager to see what is actually being done on the shop floor in real-time.

A signal interrupt is connected to the computer’s interface for each monitored machine. Cycle count and time are measured for each part cycle. Every tool is monitored and tracked in real-time.

The system offers a number of different displays for either historical tool data or dynamic information. The “dynamic display” shows which machines (up to 32) are running. Machine cycle numbers (adjacent to the machine’s number) are color-coded on the screen to show each machine’s current status in real-time. One glance can tell you if the machine is idle or running. It also displays the number of parts produced on each machine. Tool descriptions and cycles for each tool are shown. Also, part counts and time remaining for each tool are forecast and exhibited so the operator knows how soon a tool change is needed, or if a tool is producing parts beyond the scheduled change. (These are displayed as negative numbers.)

Also, notes can be input as reminders for the next shift or another operator. Machine maintenance information such as filter changes, coolant check, lube schedules and other data can also be input as reminders.

A “tooling and display setup” screen shows the tool description, cycle life, current cycle count, time left until change, machine rpm, surface feet per minute being run by the tool and any comments, such as the type of cam being used. Another display shows the perishable tooling costs with the tool description, manufacturer, vendor, life cycle, cost, cost to sharpen, number of times for re-sharpening or how many edges are available on the tool, and cost per 1,000 parts produced.

Other reports from the software include production-run, life cycle change and tool-reset reports.

One Example

At a beta site in Grafton, Ohio, General Plug and Manufacturing Co. has been using the Tool Sentinel system for 3 years. The company, a Precision Machined Products Association (PMPA) member, started business in the mid-1950s producing cold-formed parts such as pipe plugs. It has been in the screw machine business since the mid-1980s.

The types of materials used in the company’s screw machines are mild steel alloys, stainless steel, brass and aluminum. Part sizes range from 1/16 inch to 2 5/8 inch in diameter. The company also has CNC equipment that produces part sizes to 10-inch diameters.

General Plug and Manufacturing Co. employs 125 people and uses Davenports, Acme Gridley machines, CNC turning centers and a variety of cold-forming equipment to produce a wide range of cold-formed and machined plugs, reducer bushings, and specials supplied to the automotive, pipe/valve/fitting, electrical, heavy truck and fastener industries.

“We were having problems centered around our screw machines crashing, excess tool usage and inconsistent use of tooling vendors,” says John Hall, CFO of General Plug and Manufacturing. “We would use any tool that happened to be in stock at the time, and everyone would have favorites. And, we were not keeping track of tooling for each individual job.

“We had no way of knowing if one particular tool was giving us greater life than another. We didn’t use our job layouts (tooling plans) to specify tool types and recommended vendors. Now we are putting more specific tool information in the job layout along with using the Tool Sentinel system to keep track of the tooling and its life.

“The Tool Sentinel system has given us awareness of the importance of our tooling and the importance of finding out what tools really work the best,” he continues. “Our operators originally had to provide a good estimate of how long a tool will last. They would run it, check it for wear and then run more cycles. They did this until the tool needed to be replaced or re-sharpened. This added to our labor costs and machine downtime. The operator would be checking for wear on different tools at different times and never had a place to record the information so they knew how many cycles to run on each tool next time the job had to be run. Tools were being taken out of service before they needed grinding or after they should have been ground, resulting is inconsistent part quality as well.”

“Now, with the Tool Sentinel system, they can record the optimum life for each tool and know that when the computer screen says it’s time to change a tool, they need to do it. There’s no guessing.”

Tool Sentinel has also allowed General Plug to experiment with cycle speeds to get more productivity and see the relationship to tooling costs. The company has done this by increasing its speed by 10 percent. If this didn’t cause tooling problems, the company would go another 5 or 10 percent, or until wear was a concern.

Mr. Hall says the system has also reduced machine maintenance. “Before, if a tool wore out and broke, it usually caused some machine damage. By changing it out beforehand, this is eliminated. “There has been a significant decrease in smash-ups with the Tool Sentinel system. Now our operators are paying much more attention to their tools. When they begin a new operation, they are keeping an eye on the tools until they have a pretty good idea of how many parts they can make to maximize the life of the tool. They put the information in the Tool Sentinel, and they use the same tool and tool change pattern next time for consistency.”

The Tool Sentinel system can also drive a change to a different type of tool or tool vendor, such as carbide versus HSS by keeping track of the cycles and wear. Previously, this was a cumbersome and time-consuming task.

According to Manufacturing Consultants, Inc., the Tool Sentinel system will pay for itself within 3 to 6 months. The company also says that the system is one of the answers to making companies more competitive against offshore manufacturing, by continuously improving tooling, controlling costs and the methods of tool usage.

RELATED CONTENT

-

Software Controls Chip Breaking in Thread Turning Operations

This cutting tool manufacturer has developed a software module for chip control of thread turning operations in virtually any CNC lathe, even for older machines, using specific tooling and software.

-

Two New Twists on Thread Whirling

Thread whirling as a metalworking process dates to the 1940s. Recently, developments in production speeds, based on this increasingly popular process, are impacting thread manufacturers.

-

Metamorphosis of a Brown & Sharpe Department

This plant needed to maximize machine utilization and decrease labor costs. It began by upgrading its Department 417 Brown & Sharpe single-spindle screw machines.