Every month, Production Machining puts together a Technology Showcase, highlighting some of the product information that PM receives from supplier companies. For November, we focused on workholding.

Precision manufacturing would not be precise without workholding to hold the parts in a fixed position because how a part is held is often as important as how it is cut. Holding the workpiece precisely is an integral aspect of the machining process – delivering accuracy and production capabilities as well as saving setup time with faster changeovers.

In this technology review, we’re looking at a connectable workpiece positioning system for manual and electric zero-point clamping; a universally applicable, wedge-style power chuck; a zero-point workholding system engineered to maximize holding power for three-, four- and five-axis machining centers; and more.

For the latest new products across the broad spectrum of precision machining, check out Production Machining’s New Products online.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining's free monthly print magazine.

Read PM’s October’s Technology Review.

Click on each link below to read the full product post:

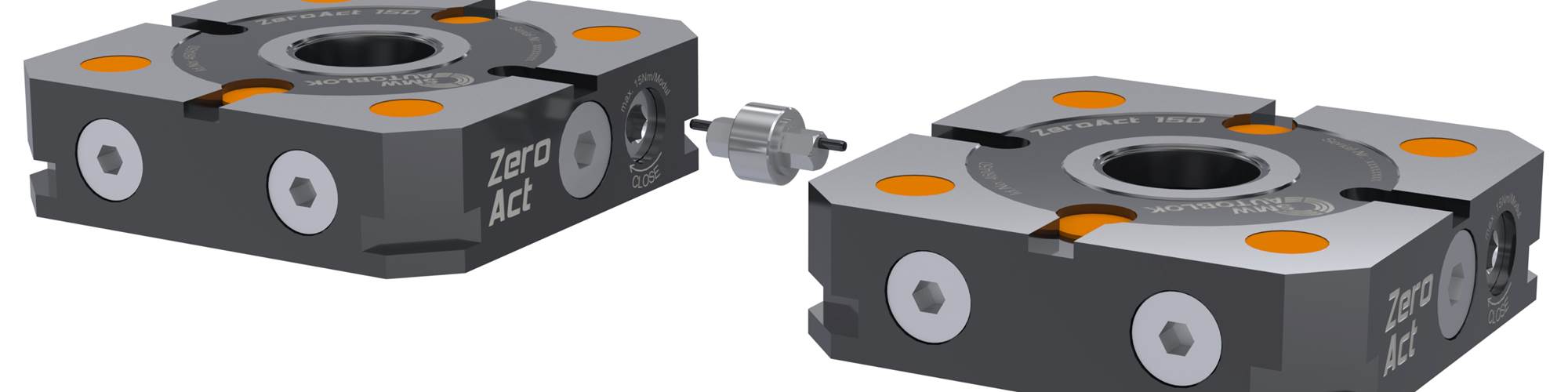

SMW Autoblok’s connectable ZeroAct workpiece positioning system is well suited for manual and electric zero-point clamping in a variety of applications, including milling, inspection and finishing operations. With a low profile of 40 mm and extremely flat design, ZeroAct is well suited for any zero-point application, especially those where the Z-axis travel of the spindle is critical.

Forkardt’s FNC+ Quick Jaw Change Power Chuck is a universally applicable, wedge-style power chuck offering increased versatility and manufacturing efficiencies as well as reduced setup time. New features and capabilities include a revised base jaw profile that enables the chuck to accept base jaws from competitive brands. This enables users to continue to utilize the current inventory of base jaws, irrespective of brand.

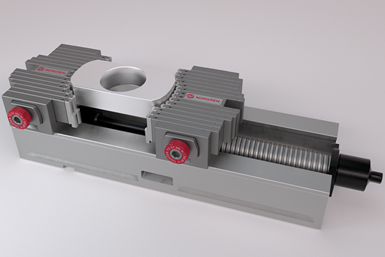

Mate Precision Technologies’ 52/96 zero-point workholding system includes vises, bases and mounting systems, and is engineered to maximize holding power for three-, four- and five-axis machining centers. Mate says its workholding system not only reduces setup times and process variability but also offers optimized accuracy and repeatability in a compact, quick change, modular design.

Norgren’s Adaptix Soft Jaw uses adjustable fingers and interchangeable tips to grip a wide variety of parts or workpieces during the computer numerical control (CNC) machining process. It was specially engineered to be a one-size-fits-all alternative to standard, single-application aluminum soft jaws.

Jergens has added new modular dovetail vises and adapter bases to its line of Fixture Pro workholding for more quick-change applications using this distinctive style of clamping. The company says dovetail vises offer secure clamping with minimal material, and are well suited for parts with multiple operations and larger metal removal. With the ability to utilize quick-change, users can spend more time in the cut and less time in part changeover.

Platinum Tooling Technologies is the North American distributor for Tecnicrafts Industries’ collets and guide bushings for Swiss-type CNC Lathes. Tecnicrafts’ collets and guide bushings are exclusively used for Swiss turning applications on Citizen-Cincom, Tsugami, Star, Tornos, Hanwha, Traub, Hardinge, Manurhin-Kmx, Miyano, Nomura and other machine brands.

RELATED CONTENT

-

High-performance milling cutters combine high cutting data with long tool life and efficiency, but certain factors must be considered when selecting tools for different machining tasks.

-

Tech Brief: Calculating Surface Footage and RPM for Optimum Tool Life

-

This article looks at the coating methods available for carbide cutting tools.