Production Machining's February 2024 News Highlights

Production Machining’s February 2024 news highlights include new facilities and expansions, partnerships, anniversaries and more.

Grob Systems Inc. recently broke ground on a 135,000-square-foot expansion project that will add approximately 35% more space for production and shipping to the existing 400,000-square-foot facility. This is expected to add 200 new jobs to its U.S. headquarters and manufacturing facility in Bluffton, Ohio.

The new, expanded space will house many of Grob’s sub-assembly departments to support final production in the main plant. On the logistical side, the expansion will provide shipping with two new depressed docks, bringing the total to three docks, further increasing the efficiency of shipping and receiving for Grob. Read more about the expansion project.

Featured Content

Here are some more news highlights:

A3 Commemorates 50 Years as an Organization

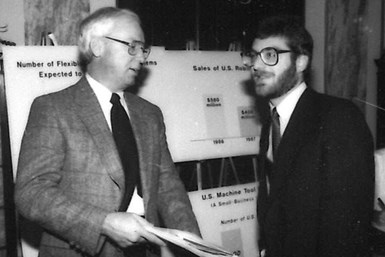

The Association for Advancing Automation (A3) celebrates its 50th anniversary in 2024. The global advocate for the benefits of automation now represents more than 1,280 member companies.

“The success of A3 for the past five decades is directly attributable to the unflagging support of our members, the incredible advances in automation technology and the resilience and talent of the team we’ve assembled,” says Jeff Burnstein, who joined A3 in 1983 and has served as president of the association since 2007.

Alro Steel Opens New Facility in Iowa

Alro Steel has announced the opening of a new location at 9620 Earhart Lane SW, Cedar Rapids, Iowa. The 197,000-square-foot, custom-built metals service center will enable Alro to provide customers throughout Iowa with cut-to-size metals and next-day delivery.

According to the company, the Cedar Rapids location has ample storage space for a wide range of metals, including carbon steel, stainless steel, alloys, aluminum, red metals and more. Shapes include bar, sheet, plate, pipe, tube and large structural shapes. The facility has multiple saws for bar, structural and precision cutting, with quick access to a wide variety of additional processing services such as plate and tube laser, plasma cutting, waterjet cutting and more. The Cedar Rapids location can also warehouse special-inventory programs.

Platinum Tooling Begins Distributing Tecnicrafts Swiss-Type Collets, Guide Bushings

Platinum Tooling Technologies Inc. has announced it will begin distributing products from Tecnicrafts Industries, a manufacturer of collets and guide bushings for Swiss-type CNC lathes.

Tecnicrafts is an ISO 9001:2015-certified company based in South India. Tecnicrafts’ collets and guide bushings are exclusively used for Swiss turning applications on Citizen-Cincom, Tsugami, Star, Tornos, Hanwha, Traub, Hardinge, Manurhin-Kmx, Miyano, Nomura and other machine brands.

Walter Surface Technologies Acquires Greenfield Industries

Walter Surface Technologies has announced the acquisition of Greenfield Industries.

With the addition of Greenfield to Walter’s portfolio, the company says it can help customers be more productive with effective, durable cutting tools solutions for a broad subset of applications.

Marc-André Aubé, CEO of Walter, says, “We are very excited to welcome Greenfield Industries to the Walter family. Greenfield brings to Walter its premium, USA-made brands (Cleveland, Chicago-Latrobe, Cle-Line, Greenfield Threading) and its robust manufacturing capabilities and infrastructure that will allow us to continue our mission to help our customers work better. Walter is always looking to provide solutions that answer the needs and challenges facing end users in the metalworking industry.”