10. Opening Up to Possibilities

As a leader in the business realm, do you find yourself investing excessive time delineating barriers rather than exploring the possibilities that lie ahead? In the landscape of modern manufacturing, numerous opportunities abound, yet the path to seizing them often seems overwhelming. True success hinges not only on the actions undertaken to propel growth but also on the perspective adopted in navigating this journey. Read full article.

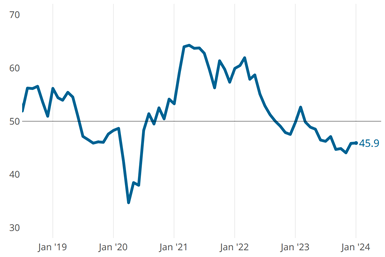

8. Gardner Business Index: Precision Machining January 2024

Source: Gardner Intelligence

The Gardner Business Index: Precision Machining started the new year the way it ended 2023, closing January with an index of 45.9, almost exactly the same as December’s 45.8. GBI: Precision Machining components were mixed in January, all of them contracting, a couple of them slower; others a bit faster and returning to December levels. Read the full article.

Featured Content

6. Robotic Automation Options for Vertical Turning Centers

The rise of robotic automation in manufacturing is undeniable. By leveraging robotic assistance, manufacturing facilities can attain a swift and uninterrupted stream of parts, reducing production expenses while enhancing dependability and precision. Explore the innovative strides made by EMAG Group in transforming production through the seamless integration of vertical turning pick-up machine technology. Read the full article.

4. The Value of RFID Machine Operator Authentication

Achieving peak efficiency on the shop floor goes beyond monitoring equipment and supplies; it hinges on understanding who holds the reins. Establishing trustworthy operator authentication is paramount for safeguarding the plant, protecting intellectual property, managing the workforce effectively, and optimizing manufacturing processes. But why is identifying "who" so critical? Explore the underlying reasons in this article.

2. Parting Off: The Case for Standardizing on Sawing

If you operate a high-volume machine shop equipped with traditional single- and multi-spindle screw machines, you may be exploring the option of rotary saw cutting (RSC). Compared to the conventional method of parting off using a static, single-point cutoff tool, RSC presents itself as a feasible alternative. Essentially, RSC involves the utilization of a thin, rotating circular saw blade, powered by a motorized attachment, to separate turned workpieces while the barstock remains in rotation. Read the full article.

RELATED CONTENT

-

Production Machining's Most-Viewed March Articles

From the integration of Artificial Intelligence (AI) into machining processes to the intricacies of CNC lathes, our coverage in March delved into a diverse array of topics crucial to the precision machining industry.