Solid Tool or Indexable Inserts? Why Not Both!

Kyocera SGS Precision Tools’ mill-turn demonstrations highlight varied tool choices and varied application knowledge.

When does an application call for an indexable-insert cutting tool rather than solid carbide? With both tooling types on display in a shared space – an IMTS first for the jointly branded company – Kyocera SGS Precision Tools is likely to have the answer. In addition to standard milling and turning offerings, SGS’s solid line includes sweeping-geometry, circle-segment “barrel cutters” and coolant-through drills, while highlights of Kyocera’s indexables range from end and face mills to grooving, turning and drilling tools.

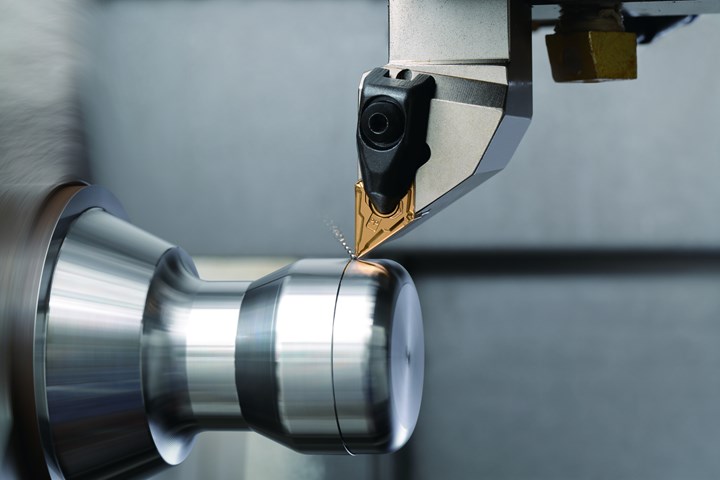

With application knowledge as broad as the jointly branded product offering, booth representatives also stand ready to show rather than tell. Live cutting demonstrations of both cutting tool types highlight where and why each stands out, while also showcasing the inherent flexibility of a mill-turn machine capable of milling and turning with both indexable or solid carbide tools.

Solid tools like the one cutting the blisk are the province of SGS, while indexable offerings like the turning tool are Kyocera’s specialty. Photo Credit: Kyocera SGS Precision Tools

RELATED CONTENT

-

Horn Carbide Grades for High-Feed Milling

IMTS 2022: The SC6A and IG6B grades complement the tool system for high-feed milling and enable customers to choose the grades best adapted to their machining applications.

-

Emag VT 4-Axes Lathes for Shaft Production Maximum Performance

IMTS 2022: The lathes are said to provide short cycle times, high-precision machining and safe processing with the VT series of turning machines literally turning the classic horizontal machining process on its head.

-

Swiss Machining Demo Shows Off Carbide Cutting Tool Lines

Pilot Precision, Palbit’s exclusive U.S. distributor, showcases Palbit’s cutting tools as well as its own broaching and drilling products.