Stretching the Limits with Swiss

This precision component supplier has high expectations when purchasing equipment. Customer requirements are intensifying, and its new technology must keep pace.

As a shop grows with increased business, new equipment is often the only solution for handling a large workload. Some shops purchase a machine to handle specific, long-term contracts, and the necessary capabilities of the machine are quite apparent. In other cases, the goal may be to obtain a machine that can handle a variety of work, providing flexibility for both current jobs and those that may come down the road. But no matter how large the shop gets, forethought is an important part of the purchasing process, ensuring that invested capital is maximized.

Relationships and Growth

Featured Content

With 15 lean manufacturing locations in North and South America, Europe and Asia, and employing 2,000 people making precision components for major industrial OEMs and Tier 1 automotive suppliers, the Autocam group of NN Inc. recently crossed $300 million in annual sales. But the group began more than 25 years ago with a single customer and only a handful of machines. Now, with about 200 Tornos machines throughout its global operations, the Autocam group considers Tornos an important partner.

In its Kentwood, Michigan, headquarters, the Autocam group uses these machines in the manufacture of ultra-precision stainless, alloy and tool steel components for a variety of high precision applications spanning several industries. These components include fuel systems, multi-speed transmissions, HVAC compressors and power tools. With tolerance requirements at ±10 microns and below, the majority of the products are used in advanced fuel systems such as GDI (gasoline direct injection) and high pressure diesel. Many of these parts have complex geometries and materials that are challenging to machine.

The company depends on its machine tool supplier not only for precise, rigid machines, but to help ensure that the production process runs smoothly. “We know processing. We know the tooling, materials, the part function, and what’s critical,” says Mike Clay, technical and quality director. “We think we’re pretty good at understanding the machine, too, but the builders know the machines better than we do. We rely on our machine tool partners to play a key role in successful process development and optimization.”

Balancing Demands

When Autocam was looking to increase production on a direct injection gasoline engine pump component, Frank Zacsek, manufacturing quality engineer, and Matt Tufer, senior technician, convinced their colleagues to consider the Tornos MultiSwiss machine. The volumes for this part did not require a fully equipped multi-spindle CNC, so the company decided instead to compare the MultiSwiss with a bank of competitive model CNC twin-spindle machines. It made sense that if the part could be produced on one multi-spindle for roughly the same manufacturing cost as several single-spindle machines, the process would benefit both Autocam and its customer. The purchase price of a MultiSwiss was higher than two twin-spindle machines, but the return on investment looked promising, so the decision was made to establish the cycle time, work on the process parameters and prove out the manufacturability using the multi-spindle.

After thorough prove-out, the MultiSwiss showed it could handle the demands of the part, and the company decided to move forward with its implementation. “With the MultiSwiss, we’re able to develop processes that finish critical dimensions, especially surface finish or flatness,” Mr. Clay says. “We’re able to do that complete in the machine where a lot of other companies would have to do a face grinding operation. The Tornos equipment allowed us to improve the process.”

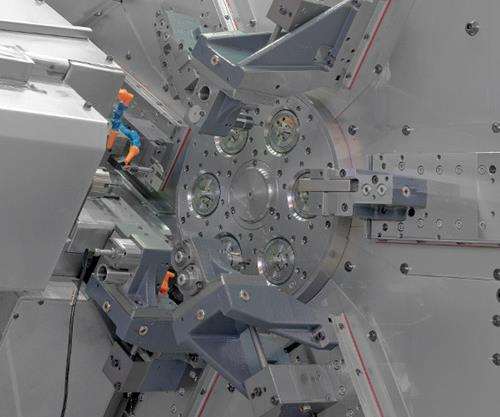

With high precision direct fuel injection components, surface finish damage to the part must be avoided. The more the part is handled as it moves from machine to machine for subsequent operations, the more opportunities exist for damage. The fact that the parts don’t have to travel from machine to machine to complete all the necessary operations and, instead, stay in one machine where turning, drilling and milling are done in six sequential spindle stations with up to three tools per position means a leaner process with reduced chance for part damage.

Always Planning

It’s a challenging part with tight tolerances and difficult material. It requires turning, drilling and milling operations on 440C material with a 7.3-mm diameter and a length of 24 mm. Tolerances on the part are ±30 microns on length and ±20 microns on ODs. Not everyone at Autocam was confident the machine could handle it. But the Tornos product engineer did a lot of work with the company to develop the part, writing the program, developing the sequencing of the operations, and working with feeds and speeds to optimize the cutting operations. One by one, everyone eventually bought into the idea of pursuing the machine for the fuel injection production part.

Mr. Zacsek says working closely with Tornos engineers was critical to making the project work. “We had two people in Switzerland for about three weeks or more. I think with developing this particular process, both organizations really worked together to make it a success,” he says. When issues arose, neither company gave up, but instead, they worked together to solve them and develop a robust process. Once it was shown to be viable, the process was transferred to the U.S. and has proven successful ever since. While a lot of time and effort were devoted to proving the machine for this particular component, Autocam does not buy machines to manufacture specific parts. They look at how the machines will be used in the future as well.

For future products, the machine spindles can be optimized, allowing machinists to hold even closer tolerances when necessary. Each spindle runs independently, so the operator can increase or decrease the speed in each position if necessary. Mr. Zacsek also likes the ergonomics of the machine. “Most of the tools are a little bit higher than on a standard multi-spindle, so you’re not bending over quite as much. And when you open the door, everything is right in front of you. It’s much better for the machinists.”

With 150 Tornos operators on staff in Kentwood alone, ease of use is also important to Autocam. According to Mr. Clay, the learning curve for machinists on multi-spindle machines is generally much steeper, but he feels the MultiSwiss removes much of the complication. “Because of the way it’s laid out, you can break it down pretty quickly in your mind and get your head around the processing and the management of it,” he says. “We don’t have operators who merely check parts. They are true machinists and understand the machines. This machine aids in developing machinists fairly quickly.”

Another advantage of the machine design is the integrated coolant lines. With the parts Autocam produces, the material is difficult to break into small chips. Chip flow is a significant consideration in part processing. Considerable downtime is eliminated by not having oil lines catching the chips.

Staying Ahead of the Curve

In recent years, one of the most significant impacts on Autocam’s business has been the development of gasoline direct injection. This technology shift required a large learning curve for the industry regarding the manufacture of these components because the material is more difficult to machine at high volume with the extremely close tolerances. The surface condition is much more critical because injectors are going directly into the cylinder.

On the pump side, the clearances are smaller and the fit of the parts is substantially tighter. Any ding or blemish is detrimental to the pump. This recent technology shift has driven the process development on all of the machines at Autocam.

Mr. Clay says he expects the same results from the MultiSwiss in the future, for the next generation of components. “We know the technological development is going to continue,” he says. “The drive for better emissions, better fuel economy, and reduced manufacturing cost is always going to be there. We need to stay ahead of the curve.” He and other company personnel are always looking at the next generation of product, and when they evaluate a machine, an important consideration is how it may help facilitate the next technology leap. They feel the MultiSwiss positions them well for the products of the future.

RELATED CONTENT

-

Custom Tooling, Workholding Help Whip Rotors Into Shape

Whipple Superchargers uses unique form tools and dead-length-collet workholding for its B-axis turn-mill enabling it to create more accurate rotors for its brand of engine power-adders.

-

Turning Machines Help Firearms Supplier Achieve Rapid Growth

Working closely with its machine tool supplier, this firearms manufacturer has quickly expanded its lineup of turning machines to deliver quality products and faster delivery.

-

When To Combine Milling And Turning

Turn/Mill technology enables users to complete a workpiece in a single handling. This article looks at some of the criteria that make application of this multi-tasking productive.