Machine operator identity is often a missing link in manufacturing data. To optimize shopfloor processes, manufacturers must know not only what machines and materials were used and at what times, but also who was in control. Reliable and secure operator authentication is critical for plant security and IP protection, effective workforce monitoring and management, and manufacturing optimization.

But why is it important to know “who?” Data-driven manufacturing is all about using data to make more informed decisions on the shop floor. It enables manufacturers to track various metrics highly granularly across the entire production cycle, from material usage to production yields to total production time. Centralized data analysis within a manufacturing execution system (MES) provides significant insight into production capacity, equipment uptime and utilization, maintenance requirements and other critical aspects of plant performance. Using data to drive decisions helps plant managers and executives identify areas for improvement, optimize processes and improve productivity and cost control.

Featured Content

RFID has commonly been used in machine shops for tracking cutting tools, but it also can be valuable in gauging human interaction with equipment on the shop floor to help drive improvement efforts.(Photo credit: Getty)

This is why shops must consider one crucial metric that is often missing in all this data: operator identity. It’s one thing to know how much time a piece of equipment was powered on, what tools and materials were used and precisely what was done the entire time a machine was operational. However, who was in control?

In many manufacturing facilities, a shopfloor employee gains access to the building and time clock in using a company ID badge, but might use other, less trackable means of authentication to access individual production cells, machines or vehicles.

Shared physical keys, radio-frequency identification (RFID) fobs or personal identification numbers (PINs) are still common for access to production equipment and material-handling vehicles. Some machines have a human-machine interface (HMI) that requires a username and password, but these can be commonly shared in some company cultures. This means managers have limited visibility into the activities of specific employees beyond clock-in and clock-out times and no way to track which workers were operating which machines at what times.

Without operator identify, manufacturers are missing an essential element of plant optimization. Reliable operator authentication at the machine level is needed to link metrics such as material use, product quality and production output to specific personnel. By monitoring workforce activity at the machine level, manufacturers can gather valuable insights into individual and team performance, enabling them to optimize processes, improve productivity, minimize variation and enhance overall plant performance.

How Workforce Monitoring Facilitates Manufacturing Optimization

Workforce monitoring refers to the ability to accurately identify individual employees and observe their activities as they interact with various machines and equipment within a manufacturing facility. This is achieved through reliable and secure authentication methods that link their unique operator identities to a specific piece of equipment at a particular time. Linking operator identity at the individual machine level — and not just at the cell or line level — provides much more detail into how employees spend their time across each shift and how individual machines are utilized, by whom and for which projects.

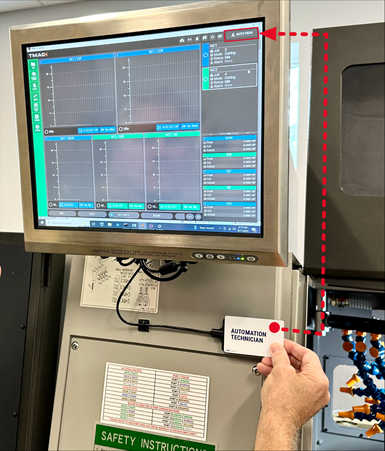

Differentiated access levels for machines can be set based on operator identity. (Photo credit: Caron Engineering)

In addition to user identification, a machine authentication system also enables access levels to be set for individual users. This prevents unauthorized or untrained personnel from operating expensive machinery, protecting assets, production processes and valuable IP that might be held on the machine such as part or tool specs. Machine authentication and workforce monitoring also support compliance with increasingly strict industry and government standards and insurance requirements for occupational safety and cybersecurity.

Access levels can also be set for different types of users based on training levels, certifications or job responsibilities. For example, different access levels might be set for line operators, supervisors and maintenance technicians that dictate which machine functions they are authorized to access, change or control. Secure access control improves plant safety and minimizes the risk of intentional or accidental damage to equipment and production line disruptions. When a manufacturer knows exactly who is operating each machine at all times, it can use that data to drive workforce and production optimization in various ways such as:

- Labor costs. What are the actual labor costs for each part going through the production line? How much time are different employees spending on each part and during which processes?

- Workforce utilization. Is the workforce fully utilized at all points in the shift or are there times when some workers are waiting for a machine to be freed up or for a more experienced technician to become available? Do adjustments need to be made in scheduling or in the physical layout of the production line to ensure that machine availability matches worker availability?

- Operator efficiency. How does each operator’s performance compare to others? Are there variations in output, quality or speed that can be attributed to individual workers? Can these differences be used to identify best practices or areas where additional training is needed?

- Machine preferences. Do certain operators perform better on specific machines or tasks? Can this information be used to assign workers to the most appropriate machines or tasks optimizing both individual performance and overall productivity?

- Safety and compliance. Are there any patterns of non-compliance or unsafe behavior among operators? Can targeted safety training and enforcement be implemented to reduce risks and ensure compliance with regulations and best practices?

- Skill gaps. Are specific skills or competencies lacking within the workforce? Can targeted hiring, training or mentorship programs be implemented to address these gaps and improve overall workforce capabilities?

Machine Authentication using RFID

To make workforce monitoring effective, manufacturers need a reliable way to track employee activities down to the individual machine and tool. A machine authentication system that crosses all tools, machines, robots, vehicles and equipment provides complete transparency into worker activities across the shift because managers know exactly where each person was at any time and what they were working on.

If authorization is confirmed, a signal is sent to the equipment HMI or PLC to enable operation. (Photo credit: Elatec)

RFID provides secure, reliable user authentication and access control for industrial machines. For most manufacturers, an RFID reader that can read the same badges that employees already use for building entry is the optimal choice. It can be easier to manage and more secure than a password or PIN system, reducing IT time/involvement and minimizing hacking risks.

Unlike shared physical keys or fobs, it enables identification of the individual operator. In contrast to biometric systems, RFID does not require workers to remove masks or gloves for identification.

RFID is reliable even in hot, hazy, dirty and high-humidity environments where technology such as biometrics, magstripe cards or optical readers can fail.

In environments where mobile device use is practical and safe, RFID readers can also be configured to allow authentication via near-field communication (NFC) or Bluetooth Low Energy (BLE).

RFID readers enable shopfloor employees to sign into individual machines quickly and easily as they go about their day. Authentication is fast and contactless. They simply wave their ID card (or, in some cases, a smartphone or wristband) near a reader connected to the HMI and/or programmable logic controller (PLC) for the machine. A unique operator identity number is used to identify each user. The reader can send information to the MES or other backend systems to enable efficient workforce monitoring and confirm that the operator is authorized to use the equipment.

Machine operator identity provides greater visibility into shopfloor employee activity, productivity, per-unit labor costs and other important metrics to facilitate data-driven decisions relative to scheduling, workforce optimization, training needs, quality control and machine troubleshooting. (Photo credit: PM)

Access Solutions for Smart Manufacturing

But machine authentication is just one access application for a “smart manufacturer.” In a unified access system, employees can use their company ID badge to access everything they need across the plant from physical access to production areas and elevators to sign on to workstations and printers, and even company amenities such as parking, EV charging, vending and a cafeteria. A harmonized access system provides even more granular detail into employee movements and activities across the shift. It also offers convenient access for employees while enhancing security and safety for the plant.

To make it all work, manufacturers need a reader compatible with the access technologies they already use for building entry and time-and-attendance. That way, employees don’t have to carry multiple cards to access different machines and applications throughout the plant. Employees are also much less likely to share their primary ID cards. A unified system is more convenient for workers and simpler for IT to set up and manage.

Elatec’s universal RFID readers offer a solution. With a universal reader, manufacturers can leverage the identification media they already have in place for easier implementation of machine authentication and other access applications. And with various form factors and a software development kit, the readers can be integrated into a wide variety of machine and device types.

Case Study: Integrating the “Who” into Machine Monitoring

Established in 1986, Caron Engineering develops sensor and monitoring technology to optimize performance, productivity and profitability for the machine tool industry. Its products interface with virtually all CNC machine tools on the market using precision sensors and high-speed data processing units to make real-time automated adjustments, optimize machining and provide valuable information about the cutting process and the machine’s health.

In addition to machine tool operator authentication, RFID can be used to ensure only properly trained employees can access and use equipment such as fork trucks and other vehicles. (Photo credit: Metalquest Unlimited)

Finding and retaining skilled operators is increasingly tricky for Caron Engineering’s machine shop customers. As a result, operator training demands are high, and so there is a need for workforce monitoring and continuous process optimization.

Caron Engineering needed a smart, secure RFID reader that would enable operator authentication and log-in to its products, including MiConnect CNC control interface software to enable those customers to use their current employee badge system. The reader needed to provide secure and accurate user identification, authorization and access control; read all of the RFID card technologies customers might be using; be easy to reconfigure for new technologies of functionality; mount cleanly and securely to the exterior controls area of their machines; and be able to withstand the rigors of industrial environments. It also wanted to ensure only authorized operators could access equipment and specific software and provide authentication so that only operators who were adequately trained could access machines.

As a result, Caron Engineering uses Elatec TWN4 Slim readers. This reader is configurable for all the major RFID card transponder technologies used worldwide — more than 60 — maximizing its market opportunities and helping it better serve customers using multiple technologies. Its customers now use the same corporate ID cards used for building entry to grant authorized employees access to its manufacturing software and equipment.

With its flexible architecture and open API, the Slim reader can be remotely re-configured to activate new card technologies or upgrade firmware to meet emerging security and functionality requirements. Or a contactless card may be presented to the reader as no touch is labor required. The Slim is integrated with the Caron Engineering middle- and backend software, so every time an operator or maintenance employee runs the equipment, it is logged along with who did it when they did it, and what actions they performed.

Caron Engineering has hundreds of its MiConnect software applications installed in locations around the world. And where it has been implemented with the TWN4 Slim reader, it provides secure, reliable machine operator authentication and access control to help its customers ensure workforce training authorization and safety to optimize their manufacturing processes.

“RFID-enabled machine operator authentication provides a check and balance,” says Rob Caron, CEO, Caron Engineering. “It helps eliminate errors by knowing exactly which operator is doing what and allows reporting back to the operator for improvement and where training is needed. They have accountability through the badge reader system.”

RELATED CONTENT

-

Introduction to Industrial Artificial Intelligence

The systematic implementation of Industrial Artificial Intelligence enables secure data sharing among manufacturers, remote monitoring and operations, managing geographically distributed assets and more.

-

Robotic Automation's Challenges, Solutions and Benefits

This article looks at considerations for implementing robotic automation.

-

Load & Go Robot Eases Automation for CNC Shops

This compact robotic loading platform makes automation affordable for CNC shops.