Advanced Metrology on Tour

A series of user group seminars and micro-shows this spring and summer will allow visitors to see and interact with the latest measurement and quality control technology.

#workforcedevelopment

Quality Vision International (QVI) has announced plans for its 2013 Western Region Technical Tour. The Tech Tour is a series of user group seminars and micro-shows, held in conjunction with QVI channel partners, where visitors can see and interact with the latest measurement and quality control technology. The Tech Tour will make five stops in the spring and summer at locations across the Western U.S:

- Rowlett, Texas – April 24-25 – at Crescent Gage and Tool Sales

- Salt Lake City, Utah – May 8-9 – at Gage Lab Products

- Denver, Colo. – June 5-6 – at Advanced Coordinate Technology

- Auburn, Wash. – June 26-27 – at Rosco Precision Machinery

- Irvine, Calif.– July 28-29 – at Pacific Inspection Company

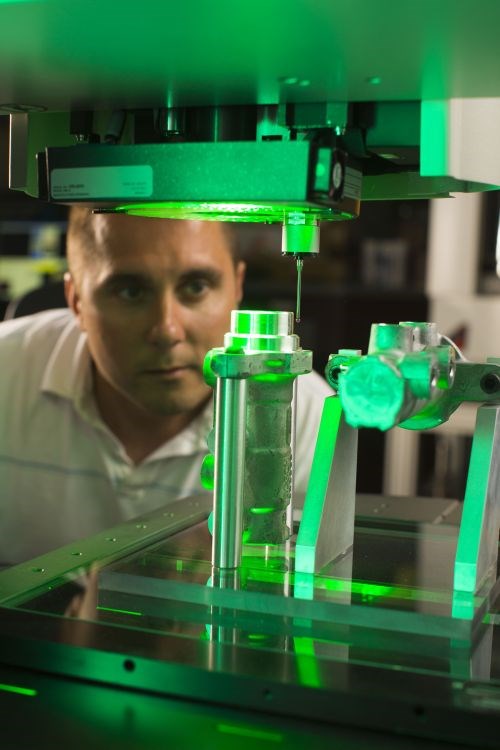

QVI Tech Tours will showcase the latest QVI-developed technologies for inspection and measurement from Optical Gaging Products, RAM Optical Instrumentation, Certified Comparator Products, and View Micro-Metrology:

- Multisensor systems for measuring complex 3D parts

- High-speed systems for measuring micro-fabricated parts near the production line

- All-new optical comparators with digital technology

- Easy-to-use manual and automatic video measuring systems

- Systems for fast and simple non-contact measurement of shafts, cylinders, and threads

Existing customers can learn new programming tips, while prospective customers can find the right solution for their applications. More information about the Tech Tour is available on the QVI website.

RELATED CONTENT

-

Winning New Jobs With Online Bidding

The digital revolution is hitting the business of the multiple-spindle automatic machining--in two distinct forms, no less. Twenty-five years after the first wave of digitization in manufacturing (numerical control) its linear descendant, computer numerical control or CNC, is changing the way screw machine shops do business.

-

Job Shop Automation: Fast, Simple and Agile

When done right, automation can provide important benefits. Here’s a look at automation options to suit the varying needs of typical job shops.

-

Determine Passivation of Stainless

Properly cleaned stainless steel is naturally protected from corrosion by a thin, passive film. But this passive layer can be removed or scratched. A passivation meter measures the surface potential under controlled conditions.