Ride this Train

Called “Train the Nation,” this popular OSG USA-sponsored training tour is back on track this year and next year. The program is an eight-discipline course covering all aspects of machining 3D parts.

#workforcedevelopment

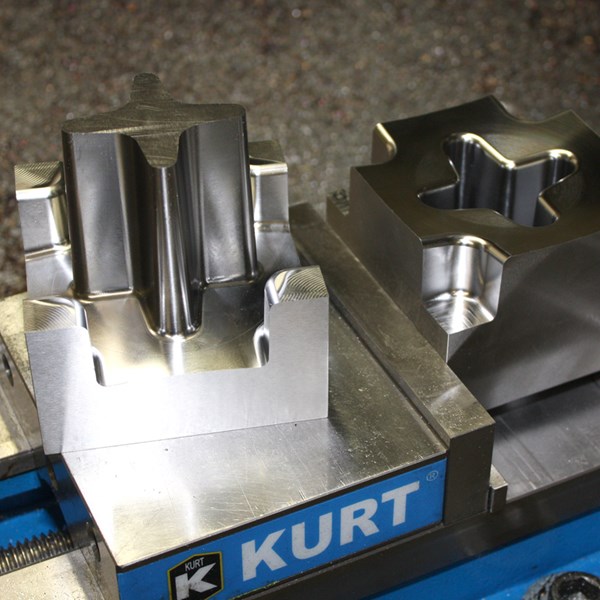

These two parts that are representative of the “how to machine it” information on tap at the OSG Train the Nation seminars.

Called “Train the Nation,” this popular OSG USA-sponsored training tour is back on track this year and next year. The program is an eight-discipline course covering all aspects of machining 3D parts. It is presented by top experts who will introduce current techniques that highlight programming, machining applications and cutting tools for successful processing of workpieces. OSG is a manufacturer of taps, end mills, drills and indexable cutting tools, located in Glendale Heights, Illinois. Its markets include automotive, aerospace, medical and die mold.

The first training session takes place in Cincinnati, Ohio, on April 7 and is the first of 14 seminars scheduled in various locations. Each training event is free of charge and runs from 8 a.m. to 5 p.m. with lunch included.

It’s an opportunity to expand the shop’s collective knowledge base by learning some of the latest techniques for machining from people who have been there. Click here to learn more about the Train the Nation content and schedule.

RELATED CONTENT

-

Metalworking Vacuum Cleaners: One Type Does Not Fit All

As the metalworking industry becomes more specialized, so does the equipment that cleans it. But as diverse as the industry is, it should come as no surprise that there is no single vacuum that can handle all of its requirements.

-

Job Shop Automation: Fast, Simple and Agile

When done right, automation can provide important benefits. Here’s a look at automation options to suit the varying needs of typical job shops.

-

Inventory Control Systems For The Shop

An ongoing effort towards more efficient operations drove this shop to take a closer look at indirect material usage, subsequently leading to implementation of a new system for tracking toolroom inventory.