Exsys ER Collet Adapter Speeds Turning Center Changeovers

Appears in Print as: 'ER Collet Adapter Speeds Turning Center Changeovers'

The adapter enables offline tool presetting for the next job while the machine continues to work uninterrupted.

Edited by Angela Osborne

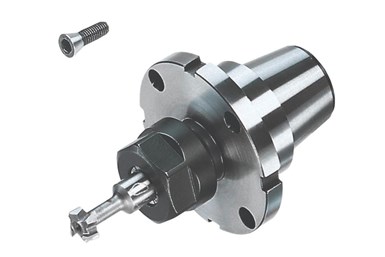

Exsys Automation Type 01 ER Collet Chuck Standard Adapter

Exsys Automation’s Type 01 ER Collet Chuck Standard Adapter enables shops to change over tools in turning center turrets quickly, accurately and economically, the company says. For machining close to the outer diameter or inner diameter of a workpiece, the Type 01 Adapter extends drills or endmills away from the face of the toolholder for additional reach.

Part of its Preci-Flex modular tooling system, the adapter also enables offline tool presetting for the next job while the machine continues to work uninterrupted. The Type 01 Adapter features a cap-style collet nut that delivers increased clamping pressure and enables it to draw the collet into the adapter pocket for stronger holding power. The adapter also offers the ability to shrink the collet pocket size without having to switch out holders.

The Preci-Flex tooling system has a single base holder and multiple tooling adapters. The company says the system’s compact design ensures maximum torque transmission and rigidity, resulting in increased machining accuracy and improved productivity. Additionally, the modular system’s conical and flat face planar interface enables the use of either an adapter or a standard ER collet, and enables collets, endmill holders, expanding collet chucks and shrink fit tooling to be mounted on a single base holder.

RELATED CONTENT

-

Collets Vs. Chucks

Find the definition, types and advantages of both CNC collets and chucks for workholding as well as the best applications for each, in this article.

-

Tools and Technologies for Deep Hole Drilling

Understanding the challenges of deep hole drilling and knowing how to select and apply the appropriate tools will help a shop profit from this operation.

-

Skiving Long, Slender Parts with Tight Tolerances

Here's a look at one of the oldest and most efficient methods of screw machine production for parts that are long and slender, with close-diameter tolerances and finishes, or parts that require truly spherical radii.