Norton Grinding Wheels Offer Long Life and Consistency

Appears in Print as: 'Grinding Wheels for Double and Single Disc Grinding'

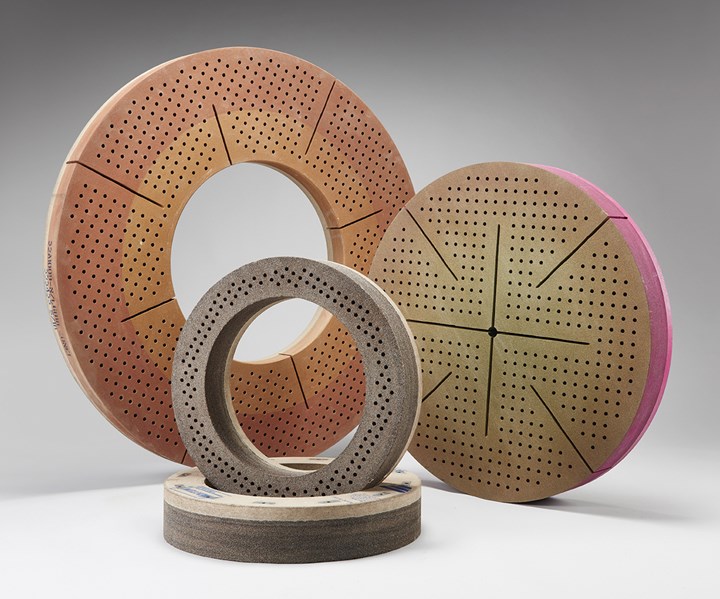

Norton Stellar grinding wheels for double and single disc grinding are suitable for automotive, bearing, tool manufacturing, compressors, knife blades and job shop/ general machining.

Saint-Gobain Abrasives’ Norton Stellar inserted-nut grinding wheels for double and single disc grinding offer improved wheel life, increased parts per wheel and lower cost per part, according to the company. The wheels are suitable for a range of industries including automotive, bearing, tool manufacturing, compressors, knife blades and job shop/ general machining.

Wheels are available in Norton's range of grains and bonds, are made-to-order to fit exact customer requirements and are available in diameters from 8" through 42" and in grit ranges from 16 through 220.

RELATED CONTENT

-

Rethinking the Grinding Cycle to Optimize Abrasives Cost Savings

For cost savings in grinding, the complete process should be examined, looking for a comprehensive solution using the latest technologies.

-

ID and OD Shoe Grinding for Thin-Walled Workpieces

Studer (United Grinding North America) has a solution to the tricky workholding problem of finish grinding close tolerances for roundness and concentricity of thin-walled rings and sleeves or a rolling element such as a bearing raceway.

-

Bond Selection for Production Grinding

Proper grinding wheel selection is essential to ensure that the required part quality, production rate, and overall cost per part is achieved. Although the type of abrasive grain is often a primary driver of wheel selection, the bonding type can also play a key role in optimizing a grinding operation.