Seco Tools' Reamers Optimize Chip Evacuation

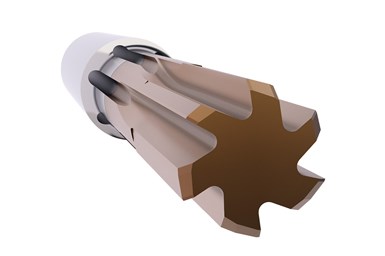

The Nanojet solid-carbide reamers are designed to stop chip jamming and enhance application stability.

Seco Tools’ Nanojet solid-carbide reamers enhance chip control with a through-coolant outlet for optimal chip evacuation. According to Seco, this design eliminates costly scrapped parts, jamming and edge damage to increase safety, part quality and tool life.

On blind and through bores, Seco’s Nanojet reamers stop chip jamming and enhance application stability. The specialized design of these new tools delivers a powerful, precise stream of lubrication directly to the cut zone for optimal chip evacuation and tool life. Seco Nanojet solid-carbide reamers maintain cutting speeds as well as part quality, contributing to production stability.

This versatile range of multi-flute reamers comes in eight grades and more than 10 geometries, along with custom sizes and tolerances. The tools reportedly work with any precision toolholder. They hold tolerances from 10 µm-15 µm (0.0004"-0.0006") and produce surface finishes from Ra 0.2 µm-Ra 1.2 µm. Seco inspects each Nanojet solid-carbide reamer and documents its measured diameter for consistent performance.

Seco Nanojet solid-carbide reamers are available in stock and custom diameters down to 0.057" (1.461 mm). Through the online Seco MyDesign tool configurator, shops can obtain customized tools with the stability, reliability and availability of commodity products.

RELATED CONTENT

-

Cutting Tool Coating Production

This article looks at the coating methods available for carbide cutting tools.

-

Calculating Surface Footage and RPM for Optimum Tool Life

Tech Brief: Calculating Surface Footage and RPM for Optimum Tool Life

-

The Many Sides of Workholding

Here's a broad look at different ways to approach workholding, from bar feeders to collet chucks to robotics.