Gardner Business Index: Precision Machining April 2023

The Gardner Business Index: Precision Machining carried into April the trend from March, moving from flat into contraction, landing at an index of 48.9.

#columns

According to Gardner Intelligence, GBI: Precision Machining component activity was generally stable in April (see last month’s reading).

- Consistency between movement in the overall Gardner Business Index: Precision Machining and some components did manifest in April, following a month in which the overall index was down while the components changed favorably.

- New order activity went from essentially flat to just barely contracting in April.

- Production activity continued to expand in April — to about the same degree as March. The same can be said for employment activity which likely reflects sustained impact of COVID-19 inspired labor shortages.

- Backlog contracted almost exactly the same in April as March, likely a function of production chipping away at orders in queue plus contraction in new orders.

The story for supplier deliveries has been the same for months. They continue to lengthen at a slower rate such that they could shorten in the near future, indicating demand is not so strong that suppliers cannot ‘keep up.’ There has to be a happy medium which is good news for receiving deliveries in full and on time and good news for the business of manufacturing.

Precision Machining Index

Precision Machining activity contracted in April, closing at 48.9.

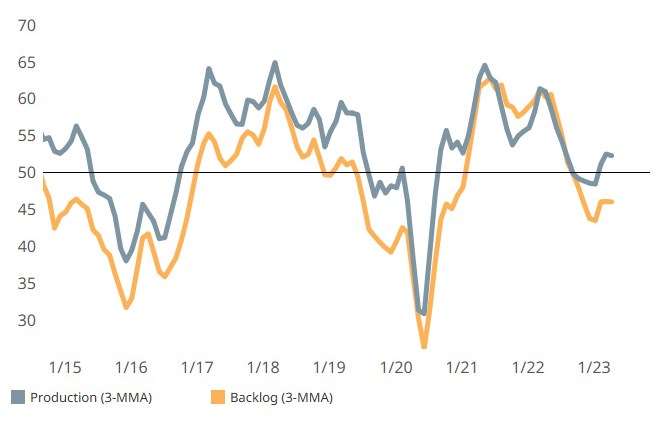

Key Components (3-month moving average)

Components, backlog and production stayed the same in April, the former contracting at the same rate and the latter expanding at the same rate as in March.

RELATED CONTENT

-

What Machine Shops Should Know About Material Bar Straightness

Many operations require a high degree of bar straightness, especially when the material is to be presented to a machine by a bar feeder. For that sector of the market, the following is a brief review of the steps your bar supplier can take to ensure positive results.

-

Get to Know Cleanliness Standards

With a small amount of practice, it is possible to understand the underlying motivation of a cleaning standard and to figure out the specific aspects of the specification that are applicable to the customer.

-

Four Human Capital Trends for 2021

One thing is for certain in 2021, changes around human capital are inevitable. In a competitive business environment, the key for leaders within our organizations is to embrace changes as effectively as possible.