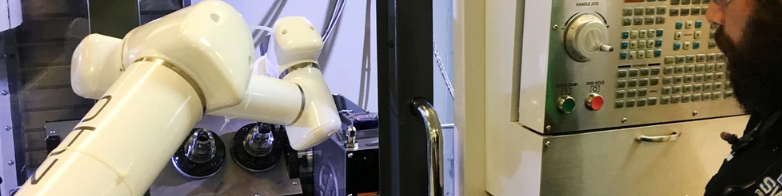

This robot machining cell consists of a FANUC M-10 six-axis robot tending a Hardinge Bridgeport V480 VMC. This automation at Custom Tool Inc. in Cookeville, Tennessee, takes out most elements of human interaction, although some operator monitoring is necessary. This setup frees up operators to do other necessary jobs on the shop floor.

At first thought, the prospect of robots is exciting: Not only are they fascinating technology but when they are integrated into the appropriate process, they can help manufacturers’ work easier, faster and more accurately. And, while most precision-turned part manufacturers are keen to the idea of implementation and understand the technology of robots, some might still be hesitant to deploy them. Of course, that’s not always true — a number of shops have integrated machine tending collaborative robots and traditional industrial robot applications which have been successful for specific processes and, as a result, benefit the overall business. But the majority of shops are wavering to take the initial steps toward adopting this technology.

The reasons for hesitation vary from cost, intimidation of existing employees, the challenge with identifying which processes to automate and so on. However, there are resources available that answer the questions many shops have prior to integration.

Featured Content

At the 2022 MFG Strong Manufacturing Summit, held at TechSolve in Cincinnati, Ohio, automation experts shared their insights about robot readiness, answering the who, why, how and what questions associated with integration. TechSolve is a manufacturing and business consultant company and serves as the Manufacturing Extension Partnership (MEP) for southwest Ohio.

Here are five action items gleaned from presentations at the Summit that can help provide a clear path toward effective robot deployment.

Identify a Purpose

Knowing the reasons for automating a particular application must be established prior to making any further decisions about robot integration.

Jack Justice, sales manager at KC Robotics, a custom robotic integrator, explains the only way to gain competitive dollar advantage with other companies that make the same product is to improve the workplace, which will lead to an increase in productivity. Therefore, considering existing tasks that are not popular among shop workforce can be a good place to start when identifying jobs that can be completed more efficiently by a robot. This can include tasks that can be done more safely or ones that are particularly dull. Also, he adds that it is worth considering any bottlenecks within processes where a robot could be a better option.

Swiss Productions Inc. in Ventura, California, added two collaborative robots (cobots) to tend a couple of its compact, second-op CNC mills. The automation enables the machines to run unattended for long stretches of time during the day and even lights out for eight hours in the evening, thereby winning the company 64 hours of nighttime, unattended machining each four-day work week. Photo Credit: Swiss Productions Inc.

Integrating robots can solve many issues like these because the technology offers safety, repeatability, consistency, accuracy and speed — which even the most skilled humans cannot always deliver.

Empower the Workforce

While understanding the advantages of automation, it might be obvious to point out a robot can help with the skilled worker shortage. However, it is critical that all employees understand that robots will improve existing jobs and are not intended to replace human workers when implemented properly. This positive perception of automation will help get employee buy-in when it comes to making automation integration decisions.

Susan Moerhing, senior program manager at TechSolve, explains how, with the number of operators retiring from the workforce and not many workers coming in behind them, automation can be a timely and valuable tool for many companies.

“If we can be smart about how we use automation, we can get a multiplying effect with the workforce we do have,” Moerhing says. That’s not to say companies should stop looking for the best and brightest in the next generation of workers, she continues, but by enabling workers to be freed up from certain types of tasks that can be created for robots, humans can complete more important work.

Evaluate Needs

Next, Moerhing recommends looking closely at shopfloor processes to determine pain points that can be entertained as candidates for robot integration. Moerhing recommends starting with consulting the operators who run the equipment. She explains they have valuable input about the weak points, problems and needs within an application.

A collaborative robot from Universal Robots (integrated by ProCobots) was recently added to a Tsugami S206 Swiss-type lathe with bar feeder at Innovative Controls (Pittsburgh, Pennsylvania). The cobot enables long stretches of unattended operation. Completed parts are pushed through the subspindle for the cobot to grab and transfer to trays. Once a tray is full of completed parts, the cobot tops it with an empty tray it will then begin loading. Stacks of trays can then be easily boxed and sent for anodizing.

Once a shop has identified a possible robot application, envisioning how the automation system will function is useful, Moerhing continues. What is the reach, load, speed, ease of programming necessary to build the most efficient process? Also, for an automation process such as machine tending, how do the robot and the machine need to communicate and what would the interface look like?

“And finally, cycle time wise, how are you doing this today?” she asks. Then, using the answers to these questions, and the data compiled, the foundation is created for one of the first conversations with a robot integrator.

Choose an Integrator

Once a shop understands why automation can positively impact a certain area of its business, it is time to dig deeper into automation options. According to Justice, finding a robot integrator that has expertise in the application to be automated is an asset to help guide a company through the exploratory process of deploying the best robot for a task.

Doing the research prior to hiring an integrator can save a lot of time, frustration and money once the automation project is underway. Justice says

While working with an integrator, it is still the responsibility of the shop’s automation champion or shop project manager to ensure that the integrator understands the automation process needed.

crucial items for integrator qualification include a Robot Industries Association (RIA) certification, sufficient staff for the project, available engineering and production time, a nearby location, financial stability and customer references.

After hiring an integrator, this person/company will make a qualified (or similar) recommendation for the automation project. However, it is still the responsibility of the shop’s automation champion or shop project manager to ensure the integrator understands the automation process needed. For example, not every robot will be suited for every process. Therefore, the integrator needs to be equipped with information such as payload and reach. And it is acceptable and necessary to check in with the integrator while working on the project.

Calculate Return on Investment

The return on investment (ROI) for integrating a robot is highly likely to be rewarding. According to Justice, payback is usually less than two years, and

Robots don’t necessarily have to be installed on the shop floor outside of a machine tool. Some machine tools include robots inside their workzones to help conserve floor space and simplify integration. In this case, a Mitsubishi robot is mounted atop a Miyano BNA 42SY from Marubeni Citizen-Cincom, as shown at this year’s IMTS.

the typical robot will last 15-plus years with scheduled maintenance. An ROI calculator, like the one KC Robotics offers online, can provide an estimate for an automation project. Justice explains that shops must evaluate whether the return will make the investment worthwhile.

Radu Pavel, V.P. and CTO at TechSolve, provided one example of a machine tending robot application that has an ROI of 9.6 months. The calculations broke down as such:

- Quantify the baseline using actual data from production. The yearly cost of the CNC lathe being considered, including operators’ salaries/benefits, cost of downtime, cost related to scrap parts, and cost of fixture and process improvement is $125,000.

- Quantify the robot investment, including peripherals. The starting investment for the CNC lathe being considered is $49,100. The cobot cost $35,000. Other cost factors are a gripper, fixture, cleaning device, visual safety device, interface, integration, and taxes and transportation fees.

- Quantify the future scenario with the cobot. The future yearly cost for the CNC lathe being considered is $63,000. Calculations encompass two operator shifts and salary/benefits, as well as downtime, costs related to scrap parts and costs for fixture and process improvement.

- Calculate estimated savings. The yearly cost savings for the CNC lathe being considered is $62,000, which factors in baseline yearly cost and future yearly cost with cobot and production enhancements estimate.

- Calculate ROI. At $49,100 investment, the company saves $62,000 yearly.

TechSolve | techsolve.org

KC Robotics | kcrobotics.com

RELATED CONTENT

-

Precision Machining Technology Review June 2023: Automation & Robots

Production Machining’s June 2023 showcase includes some of the latest automation technology from LNS, Midaco, Lexair, New Scale Robotics and Euroline.

-

Learn How to Automate Your Machine Shop at 2023 The Automated Shop Conference

Attend TASC, The Automated Shop Conference, in Novi, Mich on Oct. 11, 2023 for a comprehensive look into how to use automation to transform your machine shop.

-

Job Shop Discovers and Fills a Fishing Need

The promise of a product line for improved mounting of electronic fish finders led this Missouri job shop to an automated turning process.