Unisig Gundrilling Machine for Medical Drilling Applications

Appears in Print as: 'Gundrilling Machine for Medical Drilling Applications'

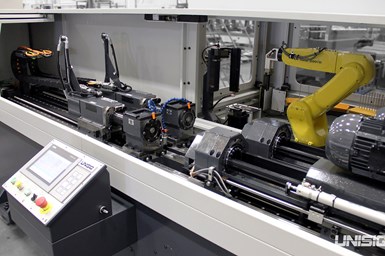

PMTS 2023: Unisig’s UNE6-2i independent spindle gundrilling machine is designed for accuracy and productivity in medical applications.

#PMTS

Edited by Angela Osborne

Unisig’s UNE6 series small-diameter gundrilling machines excel at drilling deep holes in demanding materials, including high-strength titanium and surgical-grade stainless steel, which is particularly important for medical production.

The machines are also designed to achieve superior concentricity through tool and workpiece counter rotation. The UNE6-2i features two independent, high-speed spindles for production of 10" or 30" maximum part lengths and is available with integrated automation onboard.

A key element of the machine is its ability to accommodate industry-specific workpieces in a multistep, single-piece workflow. Coupled with Unisig’s automation technologies, the UNE6-2i meets the extreme accuracy and efficiency needs of the specialty drilling market for medical equipment.

The machine’s high accuracy enables it to drill hole diameters from 0.03" to 0.25" (0.8 mm-6 mm) and depth-to-diameter ratios from 20:1 to more than 100:1 in workpieces up to 11 lbs (5 kg). With 28,000 rpm total drilling speed and a 3,000 psi (207 bar) flow-based coolant system, the UNE6-2i combines process control with an intuitive smart control interface.

RELATED CONTENT

-

Production Machining Provides Insightful, Online PMTS Planning Resource

Production Machining devotes an entire online section to all things PMTS, including an extensive PMTS new product showcase and a variety of features and columns to help visitors prepare for this premier industry event.

-

Gnutti Transfer Machine Designed for Flexibility

PMTS 2019: Gnutti’s line of transfer machines are designed for to accommodate a range of materials including lead free brass, cast iron, steel and more.

-

PMTS 2019 Recap

The 2019 Precision Machining Technology Show took place April 2-4, 2019 in Cleveland. Here’s a recap of the show.