INSPECTION & MEASURING

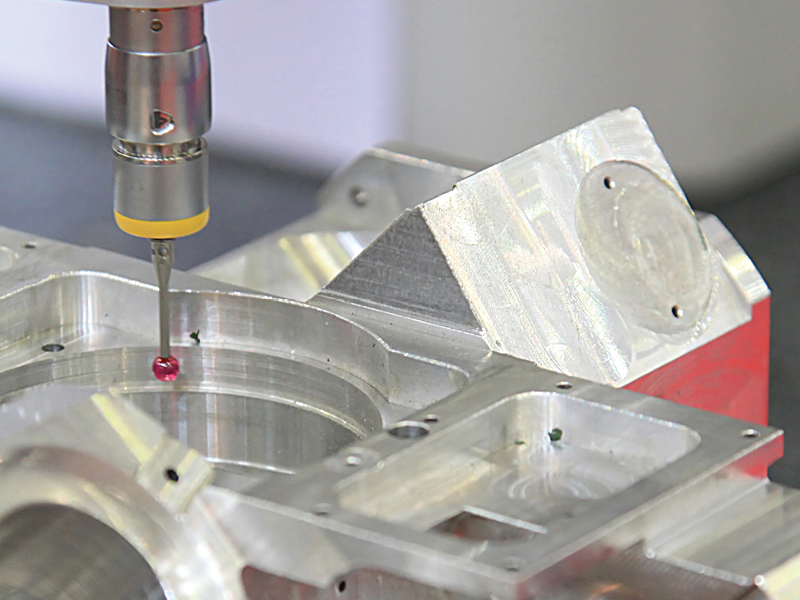

The tolerances and surface finishes for modern machined parts are becoming increasingly stringent, meaning advanced measurement and inspection devices such as gages, vision systems and CMMs are necessary.

Narrow by Inspection & Measuring Product Category

- Autocollimators

- Balancing Machines

- Borescopes

- Calibration Equipment

- Comparators, Optical & Other

- Coordinate Measuring Machines (CMMs)

- Coordinate Measuring Machines, Portable

- Data Collection Devices for Gaging, SPC, etc.

- Flatness Measuring Equipment

- Flaw Detection Equipment

- Gages, Electronic/Digital

- Gages, Mechanical

- Gear Inspection Equipment

- Hardness Testing Equipment

- Interferometers

- Laser Measurement Systems

- Leak Testing Equipment

- Material Testing & Analysis Equipment

- Probes, Electromechanical

- Refractometers

- Roundness Measuring Equipment

- Surface Finish Measuring Equipment

- Surface Plates

- Tool Presetting Equipment

- Vision Systems

- Weight Scales

FAQ: Inspection & Measuring

Does my shop need a CMM?

Although shops should always be looking for ways to be economical, the economy’s current situation is a motivation to search for even more ways to cut costs and ensure efficient processes. One way to do so, if not in place already, is to bring CMM inspection capability in-house. More and more frequently, job shop aerospace and defense customers complying with AS9100 require discrete data to be recorded and stored. Shops that don’t have this capability yet can use an outside CMM service. However, while measuring services are completely capable, inspection fees and transportation costs add up, as does the wasted machine capacity if the part must be set up and reworked. Therefore, to manage a busy manufacturing process efficiently and cost effectively, most users agree that the CMM inspection process should be in-house.

(Source: In-House CMM: An Efficient Choice)

What is GD&T? (or geometric dimensioning and tolerancing)

Geometric dimensioning and tolerancing (GD&T) conventions make clear exactly when, where and by how much each dimension is allowed to vary, with particular emphasis on allowances for material to material mating surfaces.

GD&T conventions provide practical and actionable means of controlling complex curves, shapes and forms, such as those found in medical devices that must mimic parts of the human body.

(Source: GD&T Tools Prevent Methods Divergence in Medical Device Manufacturing)

Should I balance my tools?

In the area of high-speed machining, achievable cutting speeds are consistently increasing because of new developments in cutting materials and spindles. However, unbalanced spindles, and especially cutting tools, set limits on the speeds that can be achieved. Spindle and tool longevity are also affected. And while the unbalance of spindles and other drive components can be addressed during manufacturing, tools must be balanced more frequently; usually prior to initial use in a machine tool.

(Source: Video: Tool Balance is Critical for High-Speed Machining)

Get Listed!

Thousands of people visit this Supplier Guide every day to source equipment and materials. Get in front of them with a free company profile.

.png;maxWidth=300;quality=90)