Consistency with Indirect Extrusion

A return to basics, paired with extensive research, proved instrumental in the enhancements of this aluminum rod and bar manufacturer’s product line.

#basics

Shops often consider price, delivery and customer service as the main factors when choosing a materials supplier. The quality of the materials can sometimes be an afterthought. But consistent chemistries and machinability can play a big role in the final results of a shop’s products.

Sapa Extrusions has been on a mission during the past year to enhance the quality of its line of aluminum extrusions and analyze whether or not the company is providing the most consistent, high quality products it can to its customers. Production Machining had the opportunity to tour the company’s Cressona, Pa., facility and meet with some of the management team to discuss the recent product line enhancements. Here’s a look into Sapa’s future from the perspective of three employees from the company’s team.

Featured Content

Charlie Straface, General Manager of Sapa Extrusions - Industrial

Please provide a general over-view of Sapa Extrusions’ improved product line.

Acc-U-Line is the overarching name of the product line, but within that group we have Acc-U-Rod, Acc-U-Bar, Acc-U-Hex, and Acc-U-Plate. We’re upgrading the quality of all of our products with one high quality product level and putting them under the Acc-U-Line name. These products still serve all of the same industries as the previous corresponding lines.

How do your products fit into the world of production machining?

Clearly it is our rod, bar and hex products that the screw machine shops and turning operations are most interested in. From our perspective, rod and bar product is mostly sold to the distribution community, who then services the machine shops.

What machine shops and forgers are ultimately looking for is the ability to machine the material quickly, efficiently and without difficulty. Many of the shops have now progressed to lights-out operations, which require the ability to load the machines up and run them continuously without human intervention. That’s only possible with, in our case, an aluminum rod, bar or hex that is of superior quality. The key is consistent machining and feeding through the automatic handling systems, with good chip removal and surface quality.

What was the strategy behind your recent product improvements?

We’ve been a leader in extruded aluminum alloys for many years at the Cressona facility. But other companies are always looking for ways to better compete. So we sent out our Ph.D. metallurgist, Dr. Dave (Dave Lukasak), to compare our products with our competitors’ and attempt to find the Holy Grail of machinable rod and bar.

What’s inside the product—a very consistent metallurgical structure—is the key to its quality. We’ve always said our indirect presses give us a more consistent product, but we wanted to prove that through science, physics and metallurgy. We are on the verge of investing $34 million in a new press line, and we wanted to make sure we are heading in the right direction.

So Dave came back with scientific proof that shows that, by minimizing the amount of heat that is generated, the indirect press process provides a very uniform structure from front to rear and from the O.D. all the way through the I.D. His investigation reinforced and reminded us of the science that we established many years back.

As a result, we re-centered all of our current practices back to their true form and thereby raised the quality of everything we were doing to this next level.

What else have you done at the Cressona facility to strengthen your position in the market?

This will actually be our second new press line in a couple of years. Our facility was built in 1942, but even the original presses were incredibly diverse and able to produce a range of products. Although half of our presses run the direct process, we believe we are the only company in North America using indirect presses to serve the soft alloy rod and bar market. And now we’re modernizing our processes. We’ve also invested a lot in our casting facility to make sure we have excellent quality chemistries.

While we’d love for our customers to view our newly improved product line as the greatest thing since sliced bread, they’re more likely to view it as one more way to improve their business by using a better product. Craftsmen in turning operations and machine shops, as well as anyone who understands machining efficiencies, especially know the importance of material consistency and will appreciate what we’re doing to bring a better product to market.

Also, Dave, along with our Tech Center, is working with some customers in a variety of areas to develop the next generation of machining alloys and forging alloys to hopefully further improve machinability, strength and physical characteristics of the material, depending on the end-use application. This research is related to our recent investments in our casting facilities to provide us the ability to better tailor and control composition.

David Lukasak, Ph.D., Chief Metallurgist

Explain your involvement in research for the enhanced product line.

I was formerly the quality manager here, but about a year ago, I took on the role of chief metallurgist. Based on the size of our business, there is an obvious need to focus more on next generation products and how they can further improve product machinability.

When I first began my new role, we needed to find a way to create a consistent product across all of the presses. In some cases, we were running the same product on three or four different presses and getting three or four different results. We needed to work out those issues, even if it meant that some products could not be run on certain presses.

We made a conscious decision to focus on core consistency and the inside of the metal. We focused on what composition levels we needed. We looked at how we were going to operate our presses to control the product coming off of the lines to be consistent and transparent to the customer, regardless of which press produces it, whether in Cressona or at our Spanish Fork (Utah) location.

My task was to find a way to produce consistent grain structure—a consistent product relative to what’s inside the metal. You can focus on the dimensions and do all kinds

of things to improve them. When it comes to machining, it’s what’s inside that really counts.

What were the biggest challenges you faced in achieving the project objectives?

First was getting my arms around the current condition. With eight presses here and two in Spanish Fork, I had to determine which product was being produced where—there were hundreds of sections we needed to evaluate. Based on the volume of information, it took 3 months just to establish our baseline.

What are the company’s plans for further product development?

We don’t believe we’ve completed the improvements, but have established a very good baseline for machining. We continue to do research. We have a research group in Sweden called Sapa Technology that acts as our technical resource for this project. With this group, we are developing the building blocks necessary to further enhance machinability. We’re searching for important influences, including those you can’t physically see, that affect machinability results. Birdnesting is often an issue. We’re continuously trying to understand what affects the chip formation on a microscopic level. So we’re continuing to drive these aspects of our fundamental understanding so we can apply them to the benefit of the end users.

Different compositions and different processing parameters affect the product from the time it is cast until it comes out of the extrusion process. When we are finished casting, we homogenize. As we’ve discussed, the use of direct versus indirect processes has a significant effect. The last factor is aging—our tempering process—bringing it up to final strength. Every one of these steps has an impact, so we need to determine how they relate to machinability. The general belief is that strength is critical to machinability, but we’re not convinced of that. It certainly has a role, but it is really only one component of the answer. Other factors affect chip breakage and formation just as much. This is why we are working with the researchers at Sapa Technology—to develop a more fundamental understanding of how all of this interrelates to machinability.

Al Wills, Product Development/Application Engineer

Please provide further detail of the differences between direct and indirect extrusion.

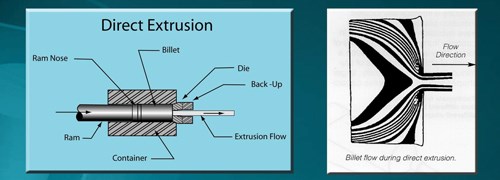

The extrusion process is similar to squeezing a tube of toothpaste as a hydraulic ram pushes the billet through a die. The direct mode process works like a Play-Doh factory; the container and die are held in a stationary position, and the ram pushes the billet forward through the die. Frictional heat is created as the billet is pushed through the stationary container, resulting in a larger temperature gradient in the emerging extrusion. The rear is often hotter than the front. The temperature variation can then have an effect on dimensions, grain structure and microstructure—all of the things that are important for machinability.

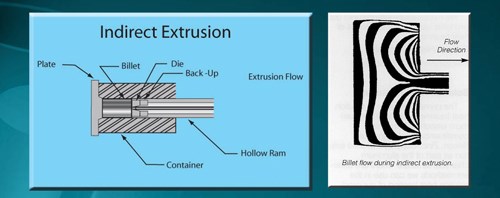

Indirect presses are more commonly used to extrude aerospace hard alloys that require high die face pressures. We have a number of direct and indirect presses with different tonnages to extrude various products for our diverse customer base. The indirect extrusion process offers many advantages for screw machine stock requiring consistent and uniform material characteristics.

In the indirect mode extrusion process, a hollow ram holds the die, and the container, ram and billet are pushed in unison over the die. The result is less temperature variation over the full extruded length and more consistent dimensions, grain structure microstructure and mechanical properties. Less die face pressure is needed to extrude a shape in the indirect mode because we’ve eliminated the frictional heat that is generated by pushing a billet through a stationary container. However, there is a trade-off that limits overall circle size because of the hollow ram, and the billet needs to be scalped to remove the cast surface prior to extrusion on an indirect press.

What are some strong points that your customers might recognize in what you bring to the industry?

We have gained a great deal of knowledge through the years and continue to learn more by working directly with machine shops to gain a better understanding of their machining equipment and needs, as well as cutting tool advancements. Automated bar feeders have brought interesting challenges to the industry, making straightness a bigger issue. We’ve made adjustments to our tolerances to compensate, cutting in half what the industry standard is to ensure the rod can easily feed through a machine.

We’ve tightened our diameter tolerances as well. In the 1960s and early 1970s, cold finish stock was the primary machining product. Through process controls and equipment enhancements, our close tolerance extruded rod and bar have now become standard products found in many screw machine and CNC shops.

What are some common misunderstandings customers may have about your business?

Most customers are very familiar with 6061 alloy, although they may not necessarily know about other alloy alternatives and their advantages for improved machinability. We’ve optimized 6061 extruded rod and bar characteristics, but if a shop is considering a change from cold finished 2011 to 6061, for example, they may still experience a difference in machinability, especially on a screw machine. Other extrusion alloys such as 6042 or 6262 are available with enhanced machinability to help bridge this gap and provide a cost effective solution.

Customers often ask why they are seeing differences in machined surface finish or chip formation between different materials. Dimensional features can be easily measured. However, what’s below the surface in the cross section of the rod is where you can find subtle differences that can have a more significant effect on machinability. Moving forward, we are trying to provide customers with additional knowledge about material characteristics and options. We want them to know the importance of overall material consistency, not just dimensionally or what you see on the surface, but what you can’t see down in the cross section of the rod, to further optimize their machining process. It really is what’s inside that counts.

— Hydro

RELATED CONTENT

-

Aqueous Cleaning for Aerospace

A turbine manufacturing plant phases out an obsolete vapor degreasing system, making the change to aqueous-based cleaning.

-

Considerations for Machining Exotics

In manufacturing, the term “exotic” is used to describe materials that display excellent wear characteristics, durability and service life in high heat, extreme cold or corrosive environments.

-

Thread Milling Tips for Tricky Aerospace Materials

Compared to tapping, thread milling offers advantages for creating threads in challenging materials such as high-temperature alloys.