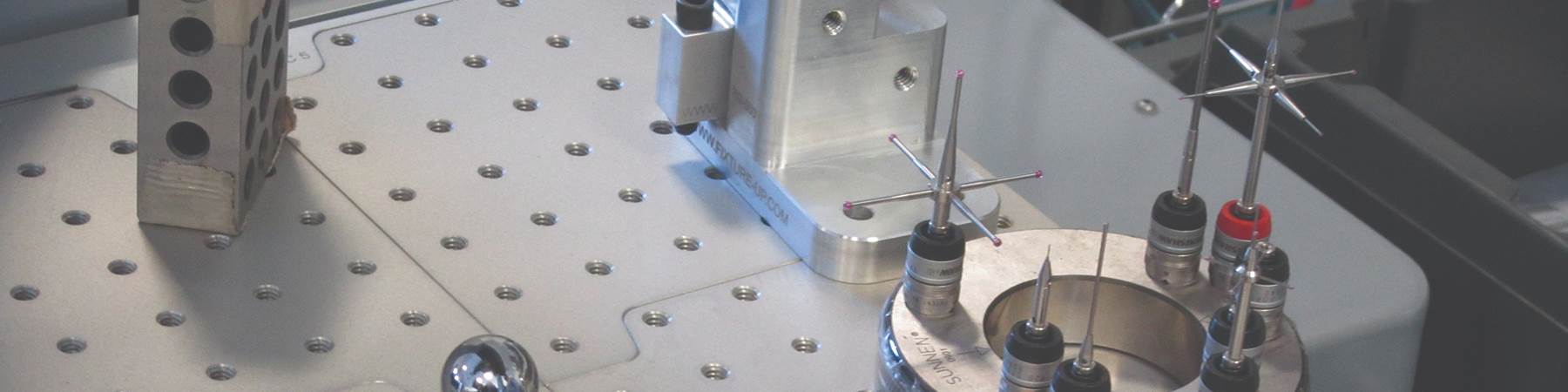

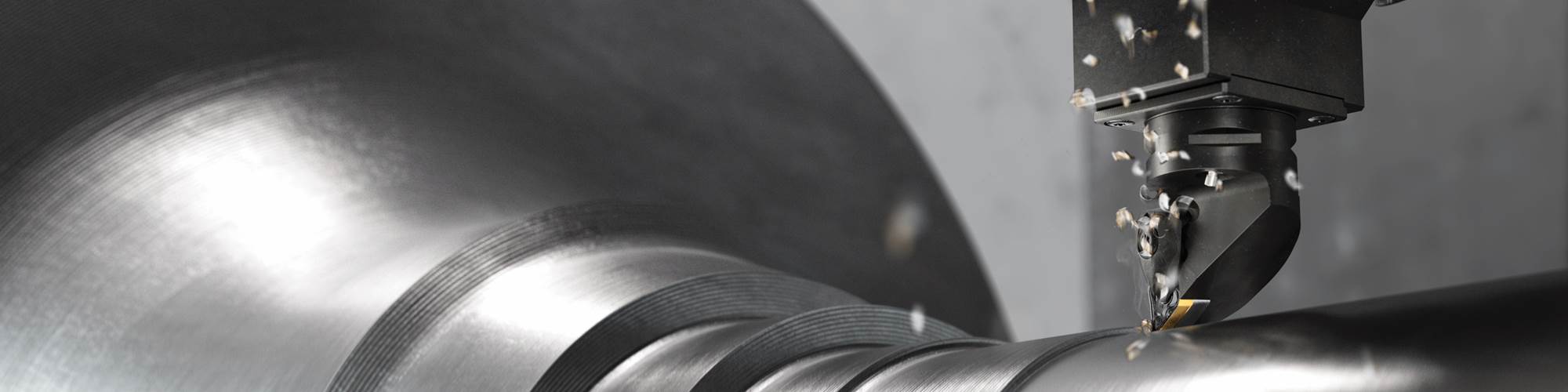

The Value of CMM Controller Retrofits

In this case, new controllers for two coordinate measuring machines — one 26 years old — with new programming software offers the possibility to enable multisensor inspection of critical, turned aerospace components.

#techbrief

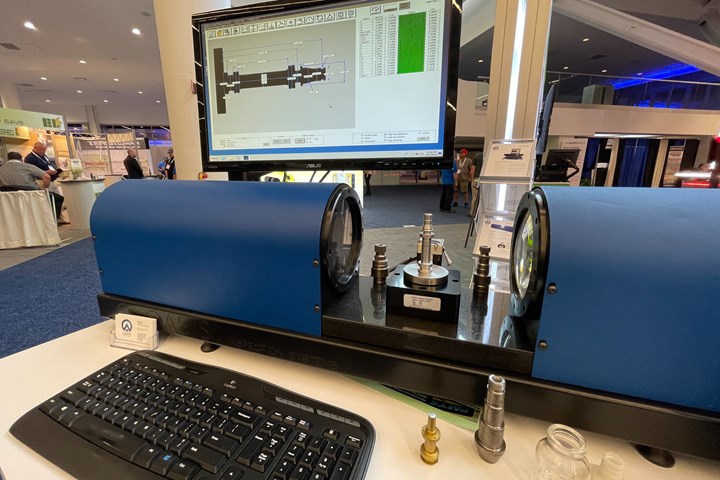

Zeiss Holds Digital Measurement, Metrology Event

Zeiss Quality Innovation Days brings together quality and metrology experts from all over the world to take part in industry-specific sessions.

Starrett Video System Provides Secure Measurement Data

The KMR-MX 200 Manual Video System is well suited for a range of industries such as medical, aerospace, defense and others that require traceable and secure measurement data.

Starrett Measurement Systems Provide Repeatable Results

The company’s optical and video-based measurement systems combine high-resolution images, intuitive software and precision mechanical platforms.