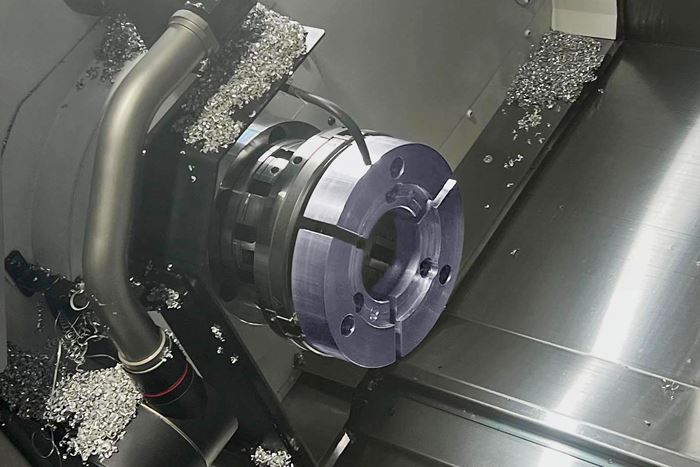

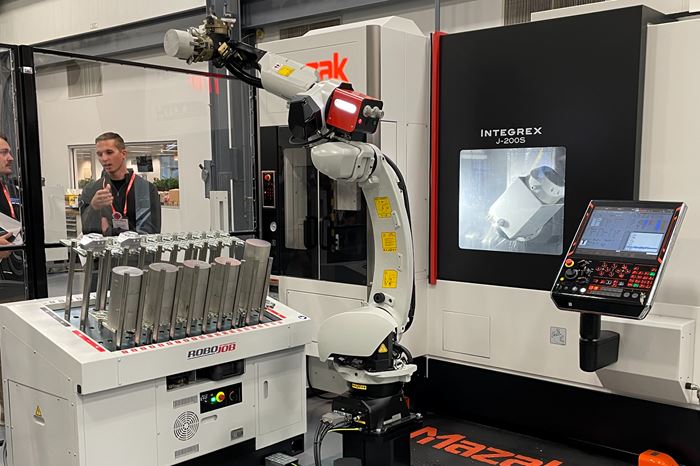

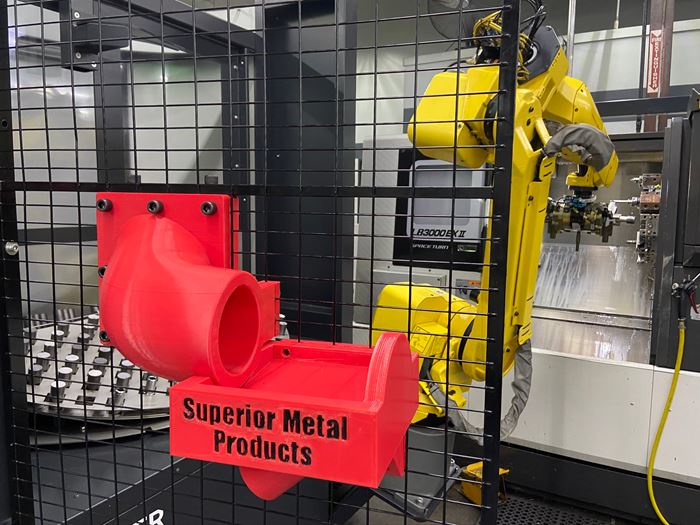

CNC machining automation can describe any operation that enables unattended processes. This can be anything from the use of bar feeders, bar pullers, robots, collaborative robots (cobots), automated data collection, vision system part measurement, tool presetting and parts cleaning process monitoring. Machine-tending robots are becoming easier to program and integrate. Cobots, those that can operate safely in the same area as humans without conventional guarding, are a good example of this. Shops must be mindful of how best to communicate the “whys” of integrating robots and other automated processes to their workforce. It is not about replacing jobs.

Pursuit of Parts Collector Spearheads New Enterprise

While searching for a small parts accumulator for Swiss-type lathes, this machine shop CEO not only found what he was looking for but also discovered how to become a distributor for the unique product.

Automation: Essential Reading

Tips for Troubleshooting and Repairing Chip Conveyors

A nonfunctioning chip conveyor can cause a high-production machine to be down for an extended period of time. Here is some troubleshooting advice if you’re having issues with your chip conveyors.

Robot Readiness: Taking Initial Steps Toward Integration

Not confident enough about automating a process yet in your machine shop? These considerations will help you better understand the path to robot adoption.

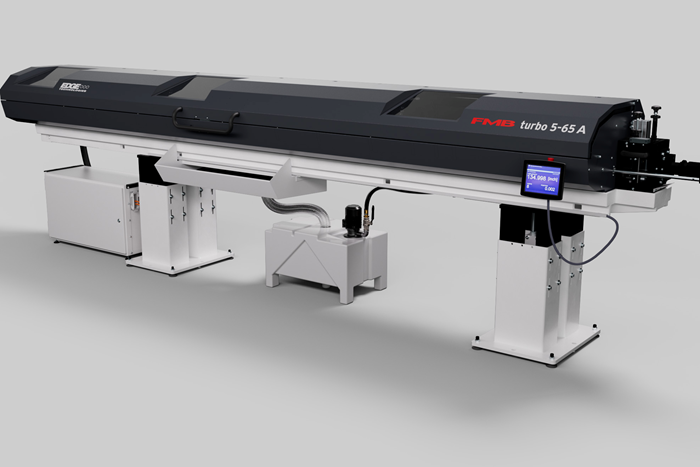

Bar Feeder Basics

Some primary factors are often overlooked when considering how to justify the implementation of a bar feeder for turning operations.

What Machine Shops Should Know About Material Bar Straightness

Many operations require a high degree of bar straightness, especially when the material is to be presented to a machine by a bar feeder. For that sector of the market, the following is a brief review of the steps your bar supplier can take to ensure positive results.

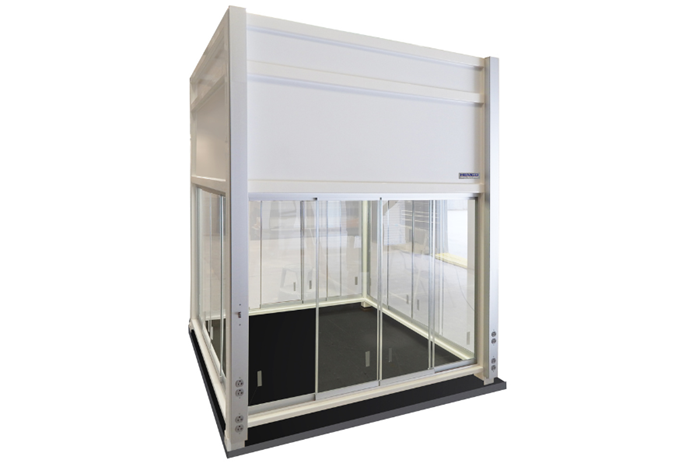

4 Questions About Cobot Integration

Many shops appreciate that cobots are easy to program and enable collaborative operation, but there might still be questions about how to install them.

FAQ: Automation

What are the advantages of automation?

The advantages of automation on the shop floor can run deep, yet many shops question whether or not it’s right for their applications.

Increased use of automation is allowing U.S. manufacturing to bring back work that it has lost in the past because of low-cost labor in other parts of the world. It’s a good idea to take the time to evaluate your production process and give deep consideration to how you can take advantage of what automation offers in achieving your goals.

Source: A Lesson about Automation

What are cobots?

The integration of collaborative robots or “cobots” has become increasingly popular for machine shops looking for ways to automate machine tending.

Although cobots vary in design, they all feature some combination of technologies that enable them to function safely alongside humans in a shared area, unlike conventional industrial robots that operate autonomously inside a safeguarded cell. Mostly resembling and functioning like a human arm (having six or seven axes), they are easy to program. Many cobot manufacturers boast that operators need little to no experience with robot programming to successfully set up and program them.

Source: 4 Questions About Cobot Integration

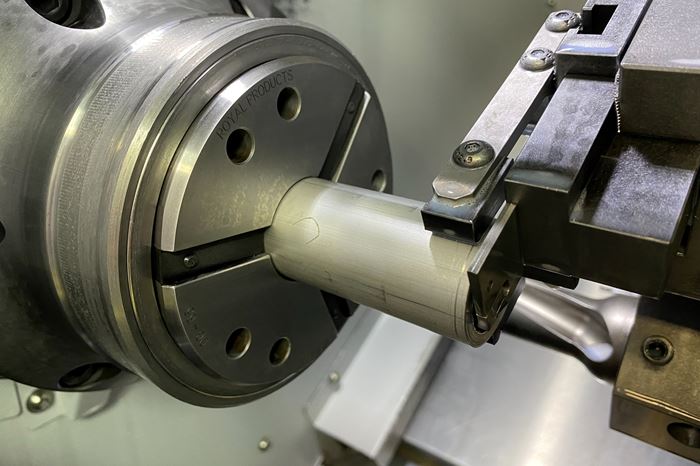

What is a bar feeder?

A bar feeder seems like a relatively simple device. The most common automation accessory in our world of high volume turning, it provides a reliable way of delivering material to the machine tool for extended periods of time, saving an operator from continually loading blanks into a chuck.

In reality, bar feeders have many nuances from one to another to make them more suitable for certain shop environments. Length and capacity are only the beginning. Other factors should be considered during the purchasing process as well.

Source: Bar Feeder Basics

How does a bar feeder work?

Other available features on bar feeders can affect how accurately the bar is fed through the machine. With a servo-driven bar feeder, the control allows the operator to specify how far the bar should be fed through the spindle, based on what is needed for the next part.

A pneumatic system, on the other hand, uses air to drive the pusher and push the bar until it hits a turret stop. Both styles have their advantages, whether cost, accuracy or speed.

Depending on the diameter of the barstock and spindle, spindle liners can be used to compensate for considerable differences. The liner is installed into the spindle, holding a good fit for the bar to help keep it straight and keeping the centerline of the material fed in on the chuck’s centerline.

Source: Bar Feeder Basics