Sometimes when shops implement a new piece of equipment, it exposes inefficiencies elsewhere in the process. These weaknesses can prevent companies from taking advantage of the new equipment’s capabilities, but switching to a new software program, tool, automation or inspection system can enable them to get the most out of their investments.

For Houston, Texas-based Geospace Technologies, an outdated CAM system was preventing the company from taking advantage of its advanced new turning center. Since updating its software, the company has improved programs for many of its parts, saving time and money.

Keeping the Data Flowing

Since 1980, Geospace Technologies has been developing innovative products for the petroleum industry, including geophones, printheads and land-to-deep sea systems for seismic data acquisition equipment. Seismic data acquisition, in particular, has become one of the most commonly used technologies in the petroleum industry to search for subsurface oil and gas.

Seismic equipment is used to collect sound data, which is then used to create maps of the earth’s subsurface. These maps help oil and gas companies search for potential or existing oil- and gas-bearing formations. For the oil industry, efficiently finding and developing hydrocarbon resources is essential. As the search for oil and gas deposits continues, seismic data collection and subsurface mapping has become one of the most commonly used technologies in the petroleum industry. And the need for accurate and cost-effective technology continues to grow.

That’s where Geospace Technologies comes in. Geoscientists use the company’s instruments and equipment to keep that data flowing—and to do so in newer and better ways. Efficiency and reliability are the keys to success, both for Geospace Technologies and for the petroleum companies that use its products.

Tight delivery schedules are another key factor for this industry. For example, it might cost as much as $300,000 per day for a company to charter a large ship for a geological survey. Forcing the ship to sit at the dock waiting for equipment to be delivered is not acceptable.

For Geospace Technologies, these constraints mean it cannot rely on external manufacturing suppliers. Outside suppliers, especially ones located overseas, have their own priorities and cannot reliably deliver products on time. The company overcomes this challenge by producing the majority of its products and components under its own roof.

Getting a Software Upgrade

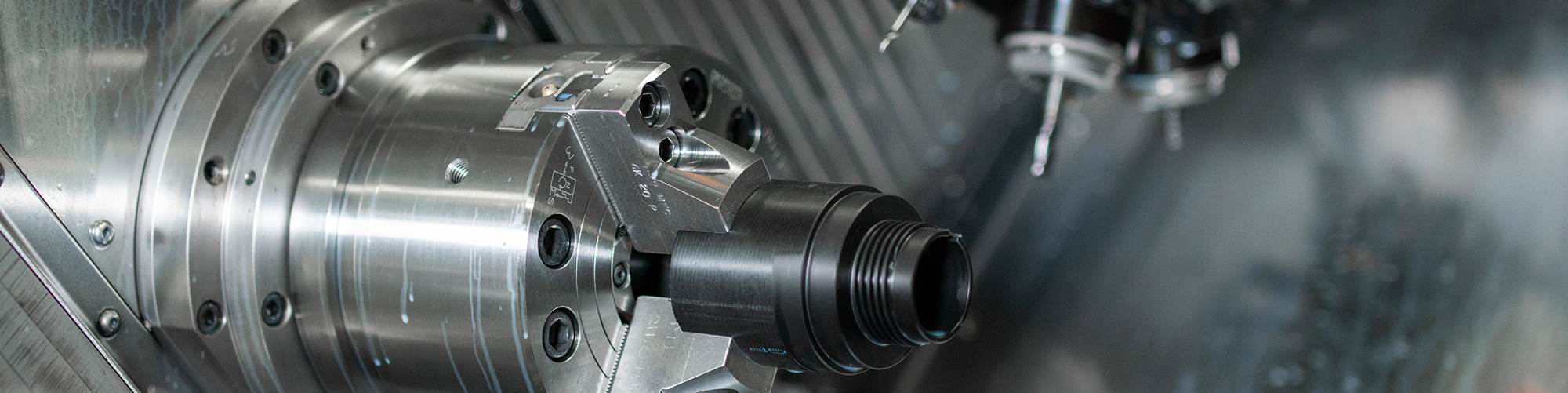

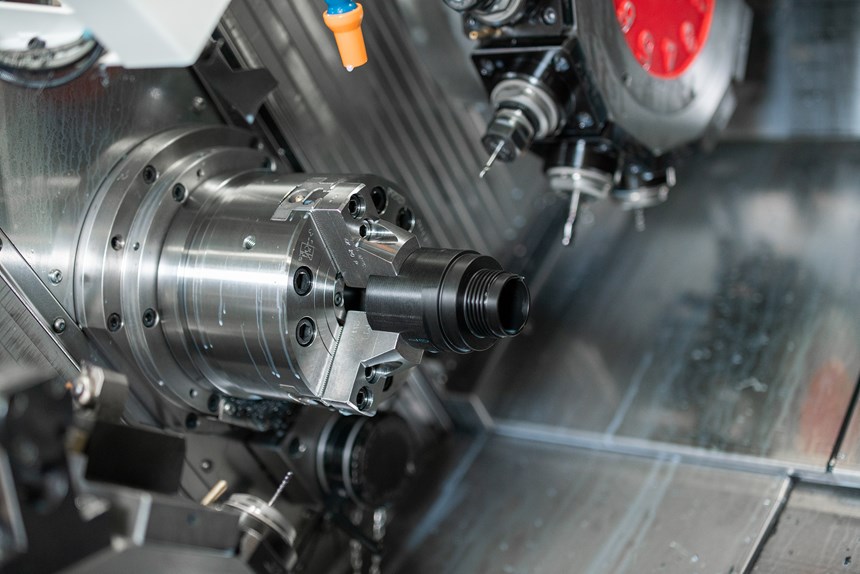

Geospace has more than 200 manufacturing employees who build molds, perform injection molding, build printed circuit boards, make machined metal and plastic components, and perform many other manufacturing operations. The company also has 33 CNC machine tools, as well as manual machines and auxiliary equipment. The company recently invested in newer, more advanced machinery, including a Citizen Miyano Machinery ABX-51TH3. This turning center has three turrets—an upper turret on the left side, an upper turret on the right side, and a lower turret capable of working on both sides.

Geospace Technologies had been using the same CAM program for years, and it initially programmed the new machine with this software. However, the company’s manufacturing engineers ran into difficulties when trying to take full advantage of the machine’s capabilities. For example, ensuring complete use of the machine’s three turrets was complicated by the fact that simply moving an operation from one turret to another often required starting the program from scratch.

Justin Henry, Geospace Technologies’ manufacturing manager, was tasked with the challenge of improving the efficiency of the company’s manufacturing options. His top priority was upgrading the company’s CAM software. Boosting efficiency with multitasking machines, such as mill-turns and Swiss-types, was key. “I looked at a few of the market leaders and selected Esprit from DP Technology because it provides the best support I have seen for advanced machines,” Mr. Henry says.

Esprit from DP Technology is a full-spectrum CAM system for CNC programming, optimization and simulation that is designed to support the entire manufacturing process from CAD file to machined part. The software also includes factory-certified postprocessors that can deliver machine-optimized G code for any machining application.

Victor Davila of Shape Design, an Esprit reseller, was brought in to assist. “We helped Geospace by showing them what they could achieve with Esprit. When we met them, they had great machines and employees. One part was missing. They were held back by inefficient CAM software,” Mr. Davila notes. “Getting more efficient, newer machines made this bottleneck more visible. I told them they could write code and take it to the machine and run good parts the first time.”

While there are several reasons Geospace chose Esprit for their machinery needs, one of the main reasons is that it gave the company more power and control to make tools do what they needed to do. Esprit is also customizable to meet the changing needs of manufacturers and machine tool builders. “Most CAM software don’t let you do that,” Mr. Davila says.

Cutting Cycle Times

After training on the new software, Mr. Henry focused on improving the program used to produce a part called an end bell that is used the company’s OBX product. It has six O-ring seals to protect electronic components from the deep-water pressure on the ocean floors during seismic mapping. Too complex to be injection molded, the end bells are machined from plastic at a rate of almost 50,000 per year.

The Geospace Technologies programmer opened the Solidworks solid model of the part in Esprit and used the software’s automatic feature recognition component to identify the machining operations required to produce each feature. In a few cases, Mr. Henry manually created features based on his own ideas on how the part should be produced. For example, he combined a bore and a counterbore into a single feature so that both could be produced with a single tool.

“We decided to flip the part around front to back in the machine because it is easier to deploy two spindles on the front side of the part, which also has most machining operations,” Mr. Henry says. The programmer set about assigning machining operations to maximize use of the turrets. For example, in the original program, a single turret produced two radial drilled and tapped holes one after the other. With the new software system, both holes are machined simultaneously on the front side of the machine by two synched turrets.

Another feature, an axial through-hole with several steps, was previously drilled and bored with four different tools. With Esprit, the programmer was able to change the way this feature was machined so that after the hole is drilled, a single carbide-insert tool is held in position to bore all steps while the part rotates. The new approach saves considerable cycle time by reducing the number of tool changes.

Geospace Technologies was also able to adjust cutting speeds and feeds to take full advantage of the capabilities of the tooling. The new feeds and speeds were tested and tweaked on the machine, and the final parameters were transferred into the final CNC program.

Another feature of Esprit that has been helpful for Geospace is the ability to perform time studies within the software. With the older software, the company was not able to get an accurate run time until the part was test run on the machine. The software, however, provides users with a report that shows how long the tool will be in the cut. Knowing how long it takes to run a part enables companies to more accurately plan jobs and report costs.

In addition to more accurate job time estimates, the software enables Geospace engineers to accurately depict how a program will run when creating or modifying a new tool. Synching turrets and collision avoidance can all be simulated in real time with the click of a button. If the synchs in the software do not match what happens in the machine, companies waste time and material proving out programs on the machine tool. According to Mr. Henry, Esprit “made it possible to move operations from turret to turret or setting sync points with a few clicks of the mouse.” Now, with more accurate syncs possible, the company can find even better efficiencies.

Overall, the new program reduced the cycle time for producing the part on the ABX machine from 22 minutes to 6.5 minutes, saving the company both time and money. Building on this success, the programmers used Esprit to reprogram an assortment of additional parts for the ABX machine and achieved even more savings.

“Esprit has given us the ability to quickly adapt and improve our CNC programs for multitasking machines,” Mr. Henry concludes. “We have achieved substantial savings by combining processes into a leaner approach, dividing operations to more efficiently utilize all machine spindles and turrets, reduce the number of tool changes required and make many other improvements.”

DP Technology | 800-627-8479 | espritcam.com

Geospace Technologies Corp. | 713-986-4444 | geospace.com

RELATED CONTENT

-

How to Get More Efficient Production from Swiss-Type and Multitasking Machines

SolidCAM for multi-axis Swiss type and multitasking machines provides a very efficient CAM programming process, generating optimal and safe Mill-Turn programs, with dramatically improved milling tool life.

-

Automatically Optimize Your CNC Machining Feed Rates

New feed-rate-optimization technology can enable CAM programmers to reduce cycle times and increase tool life for milling and turning operations.

-

Integrated Tool Management with CAD/CAM Connection

Better organization in a shop usually leads to higher productivity, and often, improved quality. That’s the objective of this modular tool data management software as it consolidates resources to encompass all aspects of production resource management.