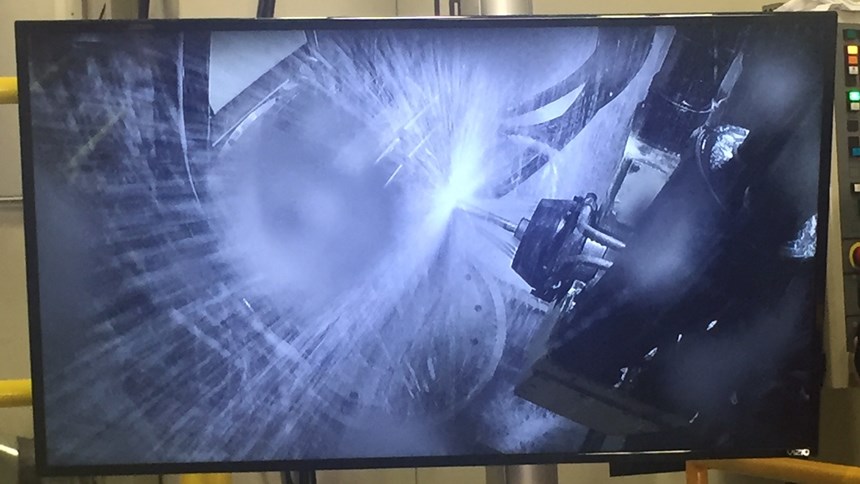

Sparks Fly at Blue Arc Technology Preview

TechSolve hosted a public unveiling of Blue Arc machining technology, which is a non-contact metal removal process that uses electro-erosion that can do unconventional and conventional machining in one platform.

On Wednesday, June 6, TechSolve hosted a public unveiling of Blue Arc machining technology at its Cincinnati headquarters. Blue Arc, first launched at the 2016 International Manufacturing & Technology Show, is a non-contact metal removal process that uses electro-erosion to produce an EDM-like surface. Developed in partnership with GE and Mitsui Seiki, it is an effort to produce parts out of superalloys such as Inconel and titanium faster and more efficiently.

Robb Hudson, CEO of Mitsui Seiki USA Inc., and Andy Trimmer, principal engineer, GE Global Research, were on hand to introduce the machine with a presentation, then a demonstration of it in action, followed by a Q&A session afterwords. The Blue Arc, according to Mr. Hudson, follows the tool path of an end mill, although he and Mr. Trimmer are quick to advise not to think of this technology as conventional machining.

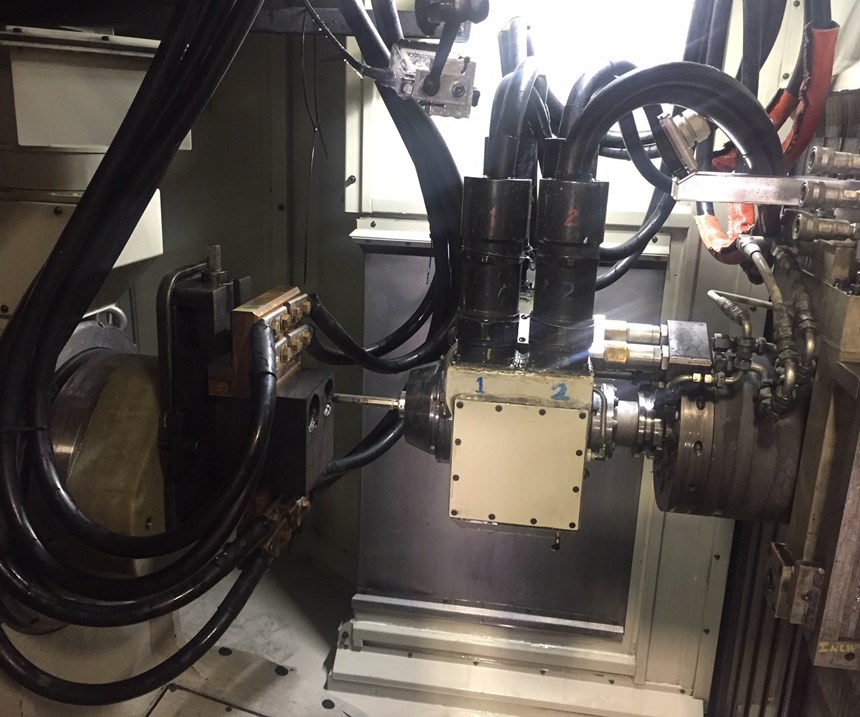

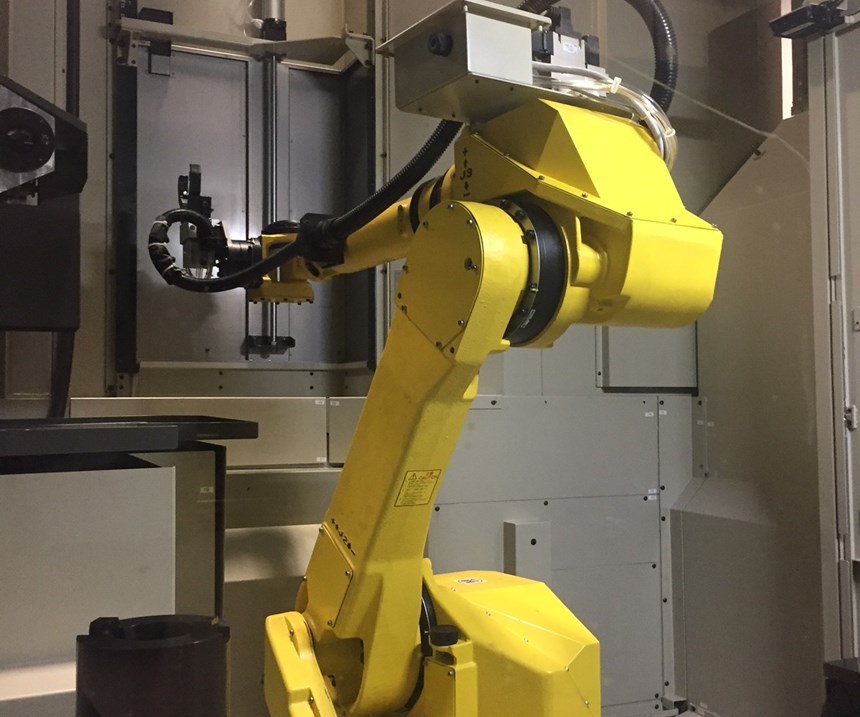

This particular Mitsui Seiki Blue Arc machine is a hybrid, based on an HW63-TD machining center, and can do both Blue Arc and conventional machining in the one platform. First, it can perform rough machining applications, such as wheel slot cutting, blade root cutting, drilling and five-axis milling. This is an impressive sight, as high-amperage, low-voltage electrical energy between the electrode tool and the workpiece is used, with portions of the workpiece melting as a result, that is quickly flushed away with a high-pressure system. Then a FANUC robot removes the Blue Arc and sets it on a station, allowing for more traditional cutting tools for turning, milling and grinding to be placed in the machine.

TechSolve will be testing the technology in the months ahead. Meanwhile, a machine dedicated solely to Blue Arc is being built in Japan.