Sandvik Coromant Cutters Complete Gears in Single Setups

Appears in Print as: 'Power Skiving Solutions Complete Gears in Single Setups'

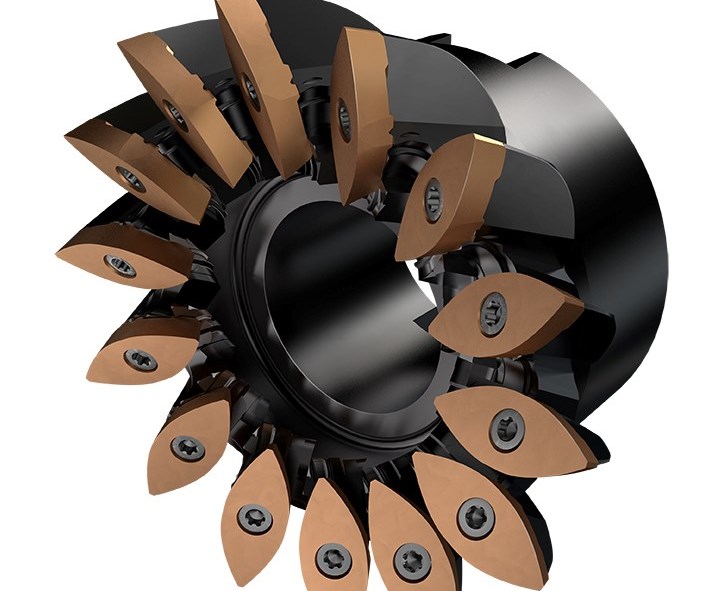

A power skiving solution composed of CoroMill 178 and CoroMill 180 cutters from Sandvik Coromant helps automotive manufacturers complete gear and spline components in one set-up on a multi-task machine or machining center.

The power skiving solution from Sandvik Coromant includes a solid bore, solid shank and indexable cutters. These tools are said to offer high tool accuracy with regard to run-out and pitch. Reconditioning can be performed as many as 10 times depending on the quality of the tool. The cutters feature a positive rake angle for light cutting action and the potential for dry machining.

According to the company, the power skiving cutters provide both high output and an optimized finishing profile. The tools are designed to meet customer specification and are said to be as much as 15x faster than shaping and more flexible than broaching. Applications include internal and external gears and splines, in addition to cylindrical spur and helical gears for automotive transmissions, and variety of other gears, coupling components, splines, shafts, synchronization rings and CV joint parts.

RELATED CONTENT

-

When Thread Milling Makes Sense

Threading a workpiece is a fundamental metalworking process that every manufacturing engineer takes for granted.

-

Tools and Technologies for Deep Hole Drilling

Understanding the challenges of deep hole drilling and knowing how to select and apply the appropriate tools will help a shop profit from this operation.

-

Bar Feeder Basics

Some primary factors are often overlooked when considering how to justify the implementation of a bar feeder for turning operations.