Editorial, News, and Products

PMPA Member H & R Screw Machine Products Finds Success in its Wide Customer Base and Diverse Machining Capabilities

When it was founded in 1976, H & R Screw Machine Products was no more than a single Brown & Sharpe screw machine in a small building located behind the home of founder, David Halladay.

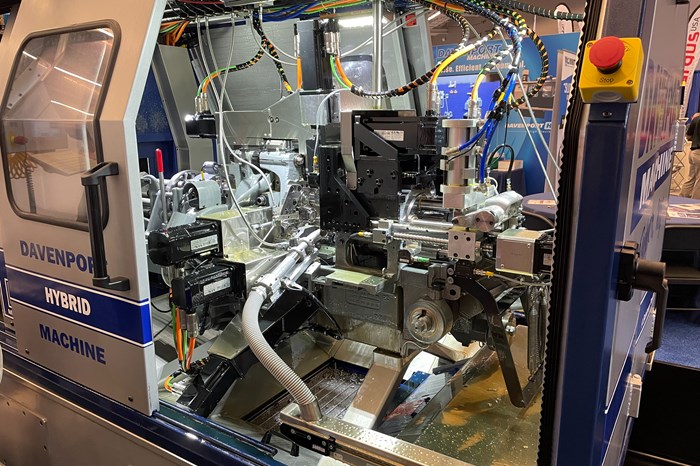

Last American Multi-Spindle Builder Keeps Moving Forward

Davenport's CEO discusses future plans for this machine tool icon in our August Last Word column. Mr. Laniak talks about the history of Davenport and his plans to move the company forward with the application of technology that makes sense.

American Multi-Spindle Icon Keeps Moving Forward

In many respects, Davenport Machine’s legacy is both a blessing and a curse.

The Davenport Rebuild

The most difficult task for us was to overcome the reputation of the old Davenport for high prices, poor quality and bad attitude. In the last decade, we have done that, I think.

Davenport: A 10-Year Update

Fooling yourself that the old machine doesn't cost anything except parts is, in my opinion, a mistake.

Moving Up to CNC for Smaller Lot Sizes

This small shop has a large presence. CNC is playing a significant role in the company’s ability to deliver parts for the big stage.

Manufacturer Stays True to 106-Year-Old Niche

Finding a niche and sticking to it sounds like common sense. Sometimes, however, companies get distracted, even bored, with a niche. That’s never been a problem for the Fischer family.

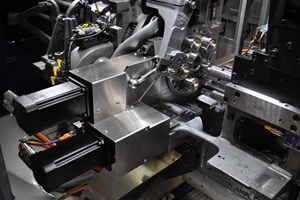

Competing On A Multi-Spindle

For many high-volume applications, multi-spindle automatics are the right technology for production machining. Increasingly, that production efficiency has been pressured by changes in the needs of shops in the form of shorter run jobs and higher tolerances. This article looks at some of the steps one OEM has taken to address quick change-over issues on its multi-spindle machines and their tooling.

Pipe Fittings Produced In A Single Operation

As with many manufacturers today, streamlining production to stay competitive in the global market has become increasingly important at this company. Thatýs why it sought out a machine to produce a double-ended pipe fitting in a single operation as opposed to having to do the back-tapping in an entire second operation.