Video Series Demonstrates Gun Part Manufacturing

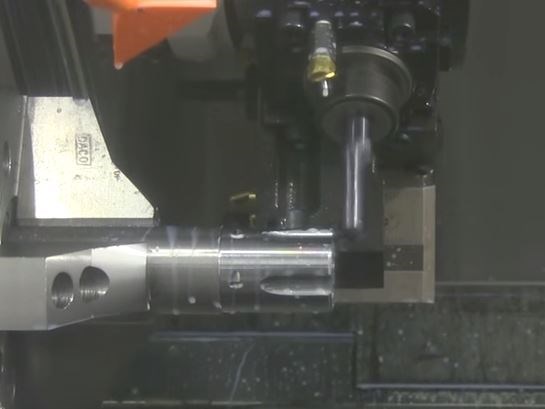

Videos show various firearms cut with high-speed precision on Okuma machining centers and a horizontal lathe.

#horizontal-and-vertical-lathes

Okuma’s new video series demonstrates CNC machines used in gun part manufacturing, spotlighting high-speed, precision cutting, live tooling, milling and drilling. Okuma’s gun part manufacturing video series includes:

- Rifle Stock Mold: Okuma’s five-axis MU-500VII vertical machining center cuts a custom-designed rifle stock mold

- AR15 Upper: An MB-4000H horizontal machining center machines an AR15 upper

- Gun Barrel Extension: Cut on an Okuma LB3000-EXII horizontal lathe, the machining of this gun barrel extension uses a variety of cutting tools and operations

- Commemorative Plaque: Using a GENOS M460-VE, this video shows the CNC milling of a gun shaped plaque for a firearms event

- 1911 Trigger Housing: Machining of a 1911 trigger housing, using an Okuma MB-56V vertical machining center equipped with a Lyndex Nikken rotary table

- Gun Cylinder: A .50 caliber revolver cylinder is cut on an Okuma LT3000 EX, 3 turret horizontal lathe

(Special Note: Some videos are filmed without the use of coolant, to better show the cutting capabilities of the machine, without visual interference. CNC machine operation without coolant is not recommended.)

To see Okuma’s gun part manufacturing video series, click here.

RELATED CONTENT

-

Understanding CNC Collet Chucks

Workholding for turning is usually fairly basic: The selection comes down to chucks or collets. This article looks at when to consider the collet chuck and what kind might be best for a given application.

-

Dry Swiss Machining in Medical

Continuing to build its reputation for creative solutions, this multi-faceted medical device component manufacturer took its Swiss machining operations to a new level to meet a customer’s market demands.

-

How Advancements in CNC Multi-Spindles Can Put You Ahead of Current Trends

Growing economic and labor pressures are making CNC multi-spindle turn/mill technology more viable than ever. This real-world comparison to a single-spindle lathe shows how.