DP Technology Releases Updated Esprit CAM Software

Appears in Print as: 'CAM Software offers Updates for Swiss-Types'

DP Technology, the parent company of the Esprit CAM system, introduces an array of software updates for 2020, including those for Swiss-type lathes.

Edited by Angela Osborne

DP Technology has released a comprehensive CAM product update called Esprit 2020. Among the most significant are updates to the software’s CAD interfaces and new or improved solutions for specific machine tools.

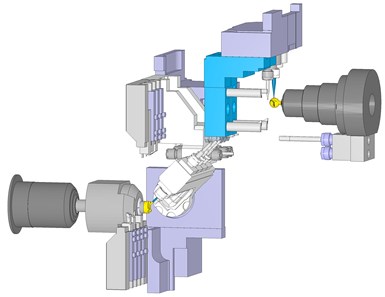

Esprit 2020 features a variety of updates for Swiss-type machining. This technique is defined by its small, often intricate parts. Medical devices (such as bone screws) are typically manufactured on Swiss-type machines. Esprit’s 2020 update introduces or enhances support for 200 different Swiss-type machine models, including Citizen D25, which features three channels — 3x Y-axis, 3x Z-axis, B-axis front and back; Star SV 38R, which features three channels and a B-axis; Tsugami SS38, a chucker/convertible sliding headstock lathe with B-axis; Tornos machines; seamless integration of laser cutting operations for Tsugami and Citizen; and Willemin-Macodel MT series machines.

The 2020 update also includes updated support for the latest CAD software, including SolidWorks 2020; SolidEdge 2020; PTC Creo 6; and NX 1847.

Improved CAD support allows users to better design and visualize parts before manufacturing begins. CAD modeling is an integral part of designing and optimizing any new part, and different software types specialize in different modeling techniques.

Additionally, Esprit 2020 expands turn-mill support to the several machines, including Index G200 and G220, featuring two and three turrets and a disk turret mounted on a B-axis; Miyano BNE 51 MSY, featuring three X-axes and three Z-axes; Traub TNX, featuring simultaneous independent machining with up to four tool carriers; and CMZ TTL, featuring two turrets and two spindles.

Enhanced profile threading and probing capabilities round out the software release.

RELATED CONTENT

-

Consider the Software Side of Cutting Tools

The intersection of the cutting tool and the workpiece it is applied to represents the very heart of subtractive metalworking. There is a significant amount of technology behind getting the cutting tool into the right place, at the right speed and the correct depth of cut. This article looks at some of the software technology that can optimize the performance of the cutting tool.

-

Integrated Tool Management with CAD/CAM Connection

Better organization in a shop usually leads to higher productivity, and often, improved quality. That’s the objective of this modular tool data management software as it consolidates resources to encompass all aspects of production resource management.

-

Automate Programming with CAM

Even for those shops still manually programming their simple parts on Swiss machines, there are compelling reasons to automate the programming process now.