Stepping Up to Unattended Machining

Lights out, unattended machining is a goal for many precision machined parts manufacturers. For many parts using easily machined materials, the process is fairly straightforward. However, this Ohio shop uses a systematic process to maximize unattended machining of more difficult materials.

The goal for many shops is to extend the unattended time that machines run good parts. The idea is to reduce the frequency of operator intervention during a job run. And like so much in metalworking, there are many ways and degrees of attaining the objective.

Featured Content

With the advancements in machine tool capability, reliability and automation, degrees of unattended machining are available to most metalworking enterprises. Moreover, the use of automation for parts loading and unloading as well as matching the best performing cutting tools for the application are critical for extending unattended operations.

While the degree of automation in many ways determines how long a given job can run unattended, pre-process planning can also impact and extend the amount of time between operator interventions during a part run. However, unattended machining is a moving target with successful results measured by increasing the number of good parts that can be processed in a given unit of time. To be successful takes a dedicated, systematic approach with continuous improvement in the amount of unattended machine time.

We recently visited a shop that has been using such an approach for a while. What’s different about this shop is that much of the material being run—exotic alloys, many for aerospace and medical applications—are generally not considered candidates for unattended machining. Yet this shop has posted significant productivity gains using its systematic approach to increasing unattended time.

Aerospace and Medical, Two Sides

of the Same Coin

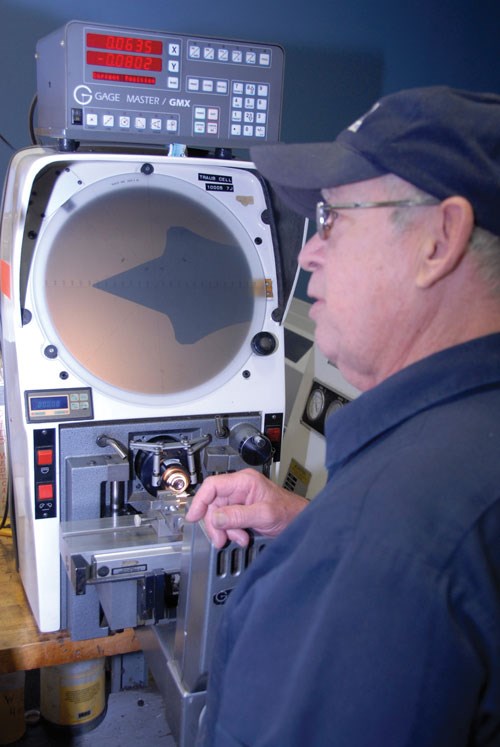

Tomak Precision (Lebanon, Ohio) is a well rounded precision machine shop and custom manufacturer capable of providing turning (including hard turning), milling, EDM, honing and grinding with a specialty in producing close tolerance work with hard to machine materials. Started in 1953, the company has been owned and operated since 1985 by a father and son team—President Al Schaeper and Al (A.J.) Jr., general manager.

For most of the company’s history, it has serviced the aerospace market. The aerospace segment of the business is concentrated in the machining of hydraulic pump parts for Tier Two and Tier One suppliers such as Parker Hannifin and Eaton. “I would consider us a Tier Three supplier,” Mr. Schaeper Jr. says.

“For our first 15 years, we were basically order takers,” Mr. Schaeper Jr. recalls. “Purchase orders would flow in, and we would sit back and fulfill them. Marketing was not in the mix. Around the year 2000, we decided that in order to grow the business, getting proactive would be a good thing, so we hired a sales person to help us identify new opportunities. We’ve increased our sales significantly.”

One of those opportunities was in machining parts for the burgeoning medical parts industry. Buoyed by its success in opening up new opportunities in 2002, Tomak fired its largest customer, which represented 70 percent of the company’s business in order to diversify into medical. By 2007, the company posted its best sales year ever and that number will be surpassed by 2011’s numbers.

“It took a while to recoup the volume from firing that customer, but that decision made us a better shop,” Mr. Schaeper Jr. says. “Interestingly, our core competency in machining aerospace parts and materials migrated rather seamlessly into making medical parts. If you’re doing aerospace, you should be able to do medical.”

However, one difference between machining aerospace and medical parts that Mr. Schaeper Jr. notes is adherence to the print. In aerospace, the print is gospel. However, while medical parts require proper geometric tolerances, there is the additional subjective complication of cosmetic. “If the part doesn’t look or feel right, the doctor will toss it out,” Mr. Schaeper Jr. says. “Of course, a doctor’s subjective ‘feeling’ doesn’t translate into a machining specification. Since most of the medical parts we make are used outside the body, it’s important that the doctor is satisfied with the look and feel of the instruments, which puts the machinist’s art alongside of his/her science.”

Investing in Capability

One of the tracks that Tomak has taken in order to grow its business is to buy smaller businesses with capabilities it doesn’t have in-house. “That’s how we got into Swiss machining,” Mr. Schaeper Jr. says. “In our case, we acquired a shop with two Citizen Swiss machines and basically moved it, personnel and customers, into our capability offering. The machinists who came with the deal taught us about running Swiss, and we were able to serve their customers. Since then, we’ve added two more Swiss machines and more customers.”

Following this strategy, Tomak set up a joint venture called RB Tool Manufacturing that basically machines prismatic parts to compliment Tomak’s primary focus on turning. This setup gives Tomak the ability to provide an array of metalworking capabilities for its customers. In 2008 it added EDM to its process mix, which is housed in the RB Tool business.

Tomak takes a slow, measured approach to capacity growth. It doesn’t go out and buy machining capacity simply to have it. “Our thinking is to buy a smaller business and allow it to teach us what we don’t know,” Mr. Schaeper Jr. says. “In doing so, we have an existing customer base to finance our learning curve and the in-house sales ability to grow that base once we understand the business and its processes.”

Doing the Hard Things

In 1998 Tomak started a hard milling and hard turning program in the shop. The program was built around the capabilities of its Mazak multitasking machine, which was equipped with both main and subspindles and live tooling.

“Back then we were ahead of the curve for hard machining,” Mr. Schaeper Jr. says. “We were machining 58 to 62 Rc with 52100, D2, M2 and M50 using the milling and turning capability on the Mazaks. We still do a lot of hard machining, but it’s less of a specialty today because many shops have developed the ability to successfully machine hard materials.”

On one turn-mill job, the price to the customer is the same in 2011 as it was in 2001. This stable price is made possible by use of the combined operations available on these multitasking machines. “It used to take us eight operations, and now we drop the part in two operations,” says Mr. Schaeper Jr.

This is an example of how the company systematically has refined how it makes parts for its customers and still maintains cost competitiveness through efficient use of technology. It continuously wrings out the costs of manufacturing, in this case, using machine tool technology.

However, the company has not stopped there. It is driving itself to further cost savings by increasing the number of parts that can be processed without operator intervention.

Opening Doors and Minds

As Tomak moved forward with its in-house efforts to increase the unattended piece count for the stabilizer part (see page 36) and others, it became evident that perhaps some outside advice might be useful. According to Mr. Schaeper Jr., “Historically, we were not very open to visits from ‘tooling’ people. In fact, from 1985 to 2000, we would not let salespeople into the shop unless specifically asked.

“However, as we went down the process development road for increasing the tool life for our unattended process, we realized that these vendors could be a technical resource for us. They helped us with hard turning and milling and were instrumental in moving us forward in unattended machining.”

Working with its local tooling vendor, Tomak selects a job it would like to see better margins on and asks the vendor how they can help. The vendor goes back and finds a tool and gives the company the cutting data with a projected tool life estimate.

Tomak then tries the new tool, but restricts its use to the first shift. The first shift counts the number of parts the new tool cuts. The second shift goes back to the previous cutter. To make sure they get repeatable results, this testing goes on for 12 shifts and is averaged into the number that is entered into the counter.

A range of 1,200 to 2,000 parts per edge would be entered into the counter as 1,500 to 1,600 parts to be safe. In this case, the original tool life was 500 to 600 parts per edge. While the insert cost was higher, the cost per part was lowered and the number of operator interventions reduced.

To make the decision about making a change in tooling, Tomak looks at tool life and the cost per part. “This process only works if you have a job/customer that is going to be stable over time,” Mr. Schaeper Jr. says. “It’s a development process that takes time to refine. Finding the right customers and being willing to invest the time, energy and money to refine that customer’s process is a key to our success.”

An Initial Example

Around 2002, Tomak was on the hunt for a medical job that promised to represent its largest volume order to date. The part is a stabilizer pin in 1704 stainless that is used to hold the patient’s head still during medical procedures. In effect, the unit consists of an external frame that has numerous, adjustable pins that conform to the patient’s head and keep it from moving.

To land the order, the company asked the customer to initially place a partial order of 5,000 pieces, significantly less than the 150,000 piece per year that it would become. “Our thinking was to demonstrate we could do the job by satisfactorily producing the first batch without risk to the customer for the full annual production,” Mr. Schaeper Jr. says. “We lost money on the first round of 5,000, which we viewed as an investment in the proof of concept. Eventually, the company won the job in total, and that’s what propelled them into looking at semi-attended machining.”

A key for any shop looking to reduce operator intervention is sufficient volume and order stability to justify tweaking the process to get maximum efficiency from it. In the beginning, Tomak’s machinists monitored the number of parts per cutting edge it was getting before the tool with the shortest life needed changing. The Mazak that it’s running this part on is a Quickturn 250 with a magazine bar feeder, parts catcher (lined to eliminate scratching) and a parts counter on the CNC, which is important for the unattended process development.

Every tool in the process was inspected for tool life. Initially, the counter was set for 600 pieces, which was the shortest edge life in the tool turret. Next, the time required to machine 600 pieces was measured, so the operator knew how long it would be between changing out the cutting tools.

“When our second shift left at 1:30 a.m., this allowed us to set the counter for 2 hours knowing the process was stable for that amount of time,” Mr. Schaeper Jr. recalls. “In the case of the stabilizer part, we got 60 parts an hour, so we got an extra 120 parts that were produced unattended. Typically on a 10-hour shift, we get 600 parts. By running the job unattended an additional 2 hours, which doesn’t sound like that much, we were getting an additional 20 percent of basically free production.”

As a testimony to how successful an approach like Tomak’s can be, currently the production rate for the stabilizer pin is 2,500 parts versus the original 600 with unattended time up to 5 hours. According to machinist Darrell Pheanis Jr., who is responsible for the job, much of the improvement has been the upgrade in tooling. One vendor the company uses has a combination cut-off/turning tool that eliminates a tool change on the machine. It is incremental improvements like this, with management commitment and the right job, that confirms Tomak is on the right process refinement track.

Using the lessons learned from the process development work on the stabilizer pin, Tomak has expanded its unattended efforts to the Swiss machine department. The idea is to take advantage of the benefits from unattended machining wherever possible.

One area is in the company’s Swiss machine department. All of the Citizens are equipped with 12-foot bar feeders, critical for success, Mr. Schaeper Jr. says. “We run lot sizes from 20 to 1,500 parts across the Swiss machines and generally simpler part geometries. In part, the number of tools available on the machine and the shorter runs we assign to them makes a detailed tool life analysis less efficient. As we found on the stabilizer pin job, any unattended work produced is a good thing. However, we also find not every job is a good candidate.”

Reducing the amount of time between operator interventions is more of a goal in many cases. However, having a plan that moves the process toward that goal is a key to long-term cost reduction.

— Marubeni Citizen-Cincom Inc.

RELATED CONTENT

-

Bar Feeder Basics

Some primary factors are often overlooked when considering how to justify the implementation of a bar feeder for turning operations.

-

Making Waves with Lathe Automation

After years of relying on an extensive machining cell for part production, this marine equipment manufacturer has now reduced part handling and improved quality through use of single-setup lathes and automated loading and unloading.

-

Smart Workholding Device Measures and Monitors

Sensor and IIoT technology combine to enable these chucks and mandrels to automatically monitor workholding parameters and measure part features to ensure process stability.