Momentum has been strong in U.S. manufacturing, largely driven by productivity increases from investments in more efficient machines, tooling and automation and the process improvements shops realize with such advancements in technology. The over-arching goal in implementing these improvements is the reduction of cycle time. Taking mere seconds out of a process, if that process is repeated hundreds of thousands of times in the production of a given part during the course of a year, it can have a quite a significant impact on a company’s profitability.

The programming implications of getting as much as possible out of such investments sometimes is not given the attention it deserves. Software companies are constantly updating their products to help shops optimize all of their shopfloor equipment. Updates to post processors and simulations are required to keep pace with the release of new machine tools. Other programming features may be added to ease the implementation of sophisticated automation equipment or multitasking capabilities.

I recently sat down with John Buehler, brand manager for production CAM at Vero Software (Tuscaloosa, Alabama), to discuss his views on what his company is doing to meet the needs of shops in this quickly changing manufacturing environment. He provides insights about how CAM systems can help bring out the best in machine tools, tooling, automation and monitoring systems.

Taking Advantage of B Axis

The evolution of machine tools has brought us new ways of cutting parts to help reduce handling, and thus also reduce cycle times and the potential for error. Multitasking functionality and B-axis capabilities allow the part to be addressed in such ways as to often eliminate the need for secondary operations. The significant benefits of the B axis are in finish, feature accessibility, contouring and the ability to reduce cycle time. But these features also bring with them new programming challenges.

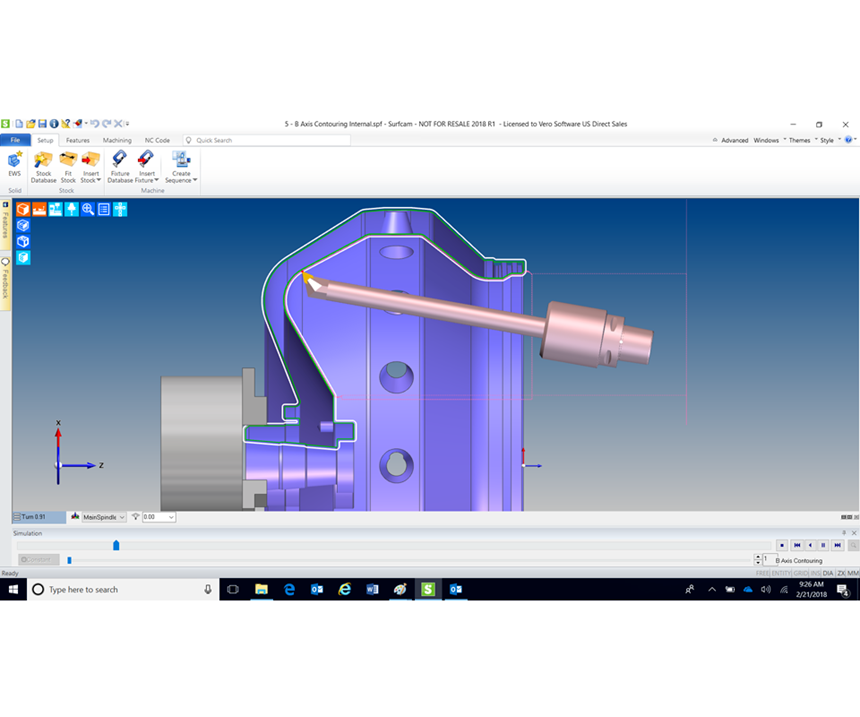

As an example of applications in which B axis is well suited, Mr. Buehler discusses shops that put a finish turn on high-value parts where controlling the angle of the tool tip allows a consistent contact point normal to the component while following the contour of the part. The shape of the part will require varying the angle of the tool. Other times, the B axis can eliminate the need for multiple tools that would otherwise need to be inserted at different angles to access certain features of a part or for multidirectional cutting, further reducing the need for tool changes.

Mr. Buehler says, like any other process optimization, it’s about taking seconds out. “A few here, a few there,” he says. “When you have hundreds of operations on a component and you can eliminate a couple of seconds each for half of those operations, suddenly you’re saving minutes per part. Thousands of parts later you’re seeing huge savings.”

One of the keys to successful use of the B axis is the ability to confidently and productively program its functionality. The CAM system needs to be capable of handling the complexity of five-axis simultaneous machining, and the programmer needs to be able to implement these capabilities.

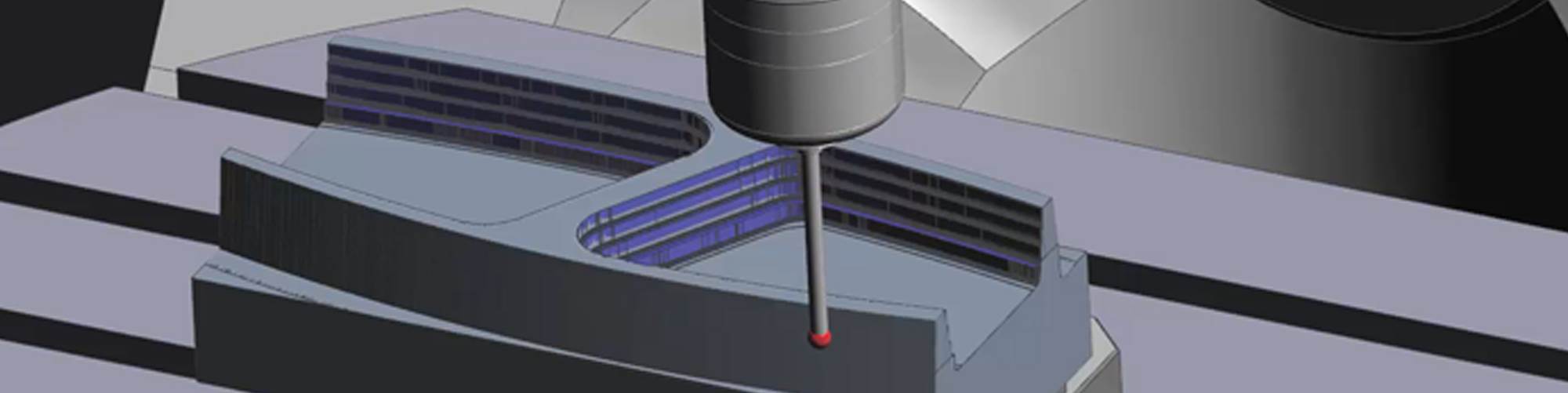

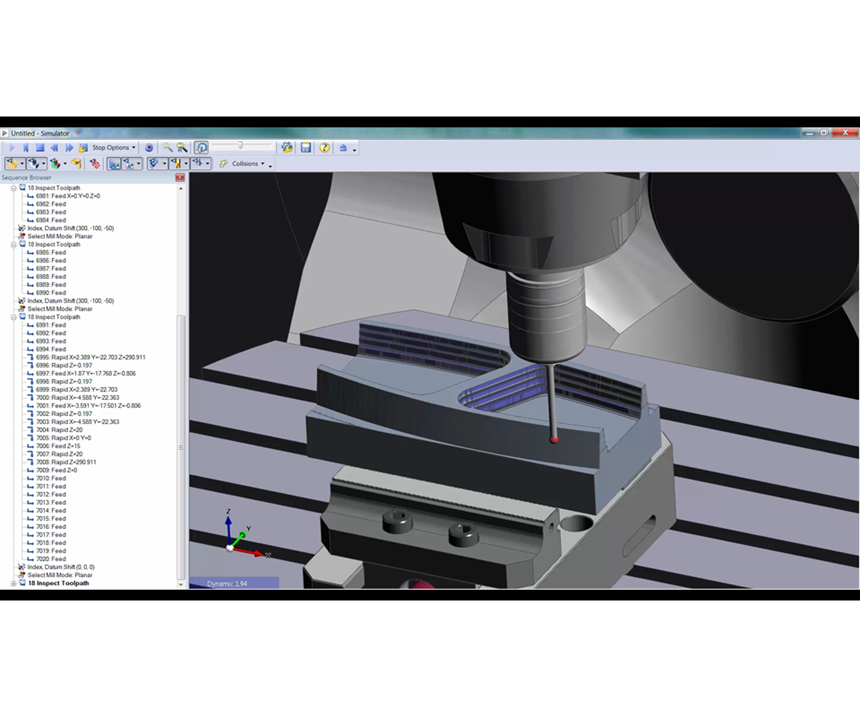

Vero’s Edgecam software is designed for precise control of the tool as it follows the cutting path. For ease of use, each toolpath has a standard template of the most common conditions. But capabilities can be expanded for full control as well. Depending on the path that is being generated, the user is likely to have control over entry and exit conditions, speed and direction along individual curves and user-defined offsets along each portion of the path.

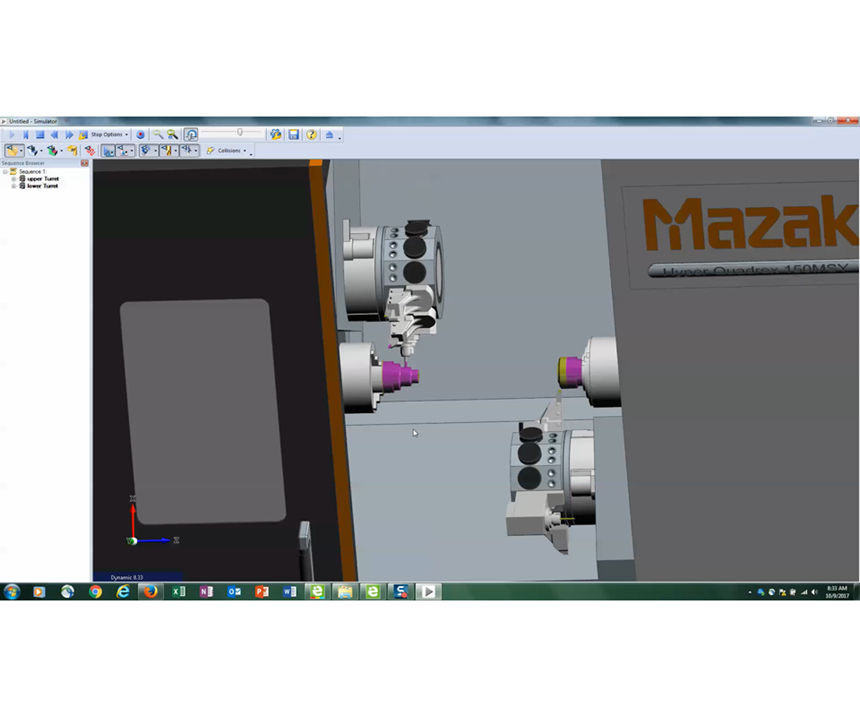

The software offers B-axis positioning on the upper turret, allowing more precise and varied approaches to mill-turn parts. The operator, therefore, can use a more flexible approach to programming complex components. The B axis can also be programmed to tilt to any number of angles to allow the many milling options available to tackle numerous feature types, such as faces, pockets and holes. B-axis machining on both the main and subspindles maximizes productivity for optimum machine performance.

The need for B axis has been spurred by the increased geometric complexity of parts, and with that has come increased risk of machine and tool collision errors. To handle such concerns, CAM software should be equipped with 3D simulation capabilities. Edgecam offers a full kinematic simulator with collision detection for four- and five-axis simultaneous work. This simulation provides accurate visualization of the part being cut before release to the actual machine.

Tooling

With the development of new materials and as part complexity increases, tooling manufacturers continue to make adjustments to their products as well. CAM software must be able to compensate for the many different variations of inserts that require even only slightly different control. The way that B-axis capabilities require the tool to follow the contour geometry of the part has had an influence on the design of these tools.

Most of the time, minor changes in tool geometry are accommodated automatically with an additional modifier or two added to existing toolpaths that will support the new tool’s required motion. More often than not, these changes are sufficient to accommodate the new tool, allowing proper cutting based on the updated geometry. Sometimes, though, an entirely new toolpath will need to be designed to support a new tool. For example, maybe the old tool would always cut in a single direction and the new tool generates better results by varying the cut direction based upon a new set of rules. Vero will partner with the tooling vendor in the development of this toolpath.

Mr. Buehler says many of his customers are doing external and internal contouring for finishing operations on high value parts. “They need to be able to control the tool low and slow while they bring it in to get good cleanup. Any time you’re in a collision-rich environment such as with turn-mill, the fewer tools you can use, the better off you are,” he says. Implementing B axis often provides the ability to use fewer tools because multiple setups of an insert are not required to cut different portions of the part.

And of course, more tools create a higher likelihood of collisions. “It’s common for operations to require multiple spindles and multiple tool turrets running at the same time,” Mr. Buehler says. “Any time you can minimize tool changes by eliminating tools from the process, that’s the better option. On a B axis, the same tool can be used on either the left or right side. The ability to cut on the main or subspindle saves tool changes and saves time. It’s the most effective way to cut.”

Digital Automation

While we’ve already been discussing the goal of shops to cut time out of the manufacturing process, we should not forget the other major challenge facing manufacturing employers today—the difficulty of hiring qualified personnel. These two challenges are not unrelated.

Mr. Buehler says when automation first gained strength, it was recognized as a tool to augment workers and help companies become more productive in times of growth. In the 70s and 80s, while companies grew they added machines and related automation alongside people to increase production capacity. However, by the early 90s, automation was bringing such rapid improvement to productivity that it began to negatively affect the number of jobs available. Because of that trend, the percentage of people entering the manufacturing workforce began to dwindle.

Now, during periods of growth, when manufacturers want to increase capacity, they often come up short on personnel and therefore are unable to man any equipment they may like to add. As a result, the need for technological advances in automation increases even further.

To help alleviate some of the difficulties caused by lack of qualified personnel, companies such as Vero continue to develop new methods of improving efficiency through automation. On the software end, these improvements can be found in smarter tool paths that reduce unnecessary tool movement (for both B axis and in other processes) and tool changes.

Mr. Buehler says the company is also addressing other areas such as inspection and measurement. Vero Inspect, a relatively new product, is designed to facilitate on-machine, in-process measurement by running a probe as a tool within the machine. Vero’s relationship with its parent company, Hexagon Manufacturing Intelligence, has helped in the development of a tool that supports a range of probe and machine tool manufacturers with embedded probe cycles and a comprehensive set of measurement features.

Inspection is only one example in which the company is addressing the quickly advancing developments of digital manufacturing. “Vero is a combination of seven CNC products, working hard to work more cohesively and share technology,” Mr. Buehler says, “and as we function more and more as a single unit, we share components and data collection capabilities across our products.”

The Vero portfolio now includes the FASys tool management system, Workplan shopfloor management, and Javelin MPR software, along with other products that are also being integrated into the CAM products to provide a more cohesive environment.

What Everyone Wants

Manufacturers are collecting more data than ever, with the ultimate purpose feeding into the same long-standing goal—trimming time out of the production process. Monitoring machine tools for hours on the spindle, average load on the spindle and average travel of the spindle, or monitoring the life of tooling, can provide valuable data surrounding machine maintenance and uptime. Again, it may come down to seconds, but the more efficiency a shop can add to its processes, the more profitable it becomes. When this data is processed and applied automatically through the CAM package, optimized toolpaths can be efficiently generated to cut the path in the least amount of time possible.

Related Content

How AI and Digital Twins Might Shape the Future of CAM

The manufacturing world will achieve gains in part-programming productivity and flexibility with the rise of machine-aware, smart digital twins powered by artificial intelligence.

Read MoreKeeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

Read MoreWho Are the DFM Consultants? You Are.

Modern shops are bolstering their engineering staff to better offer design for manufacturability advice to their customers. Here, one industry expert suggests ways to develop a common language between manufacturing and engineering.

Read MoreGet with the Program(ming): 10 Articles to Help You Transform Your Data

Collecting data but not sure how to use it? You’re not alone. See how smart shops are turning raw machine data into real results—better decisions, smoother operations, and measurable ROI.

Read MoreRead Next

Handling Machining Complexity with CAM

With the increase in demand for closer tolerances on difficult-to-machine parts, shops look to improve efficiency through simplified processes.

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreHow To (Better) Make a Micrometer

How does an inspection equipment manufacturer organize its factory floor? Join us as we explore the continuous improvement strategies and culture shifts The L.S. Starrett Co. is implementing across the over 500,000 square feet of its Athol, Massachusetts, headquarters.

Read More