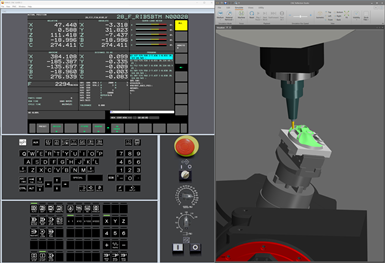

CNC Guide 2, FANUC’s CNC simulation tool, can be used in conjunction with CNC Reflection Studio, the company’s CNC machine simulation tool, to simulate accurate machine motion and to verify G-code programs. Source: FANUC America

New digital tools are breathing innovation and life into more areas of manufacturing. However, many questions still surround this technology, particularly when it comes to applying digital twin technology for CNC machining.

A digital twin is a virtual model of a physical product or system that simulates real-world behavior using data. FANUC America says its Smart Digital Twin Tools can accurately reproduce the machining process in a machine tool in a virtual environment, enabling manufacturers to detect and solve potential issues before actual production begins.

Digital twin tools offer several advantages in CNC machining. One benefit is cost savings due to reduced material waste and time by validating processes before actual machining. Another is process improvement by minimizing rework in both machining and programming by digitally verifying prototypes. A third is quality enhancement through improved quality visualization and traceability due to digital process analysis and optimization.

These tools can also mitigate challenges such as predicting production outcomes before machining begins. This uncertainty can affect production quality and lead to inefficiencies in planning and scheduling. Additionally, unforeseen issues, such as machine collisions or tool damage due to programming errors — which can result in substantial unbudgeted cost and time expenditures — can be avoided.

By reducing scrap and accurately estimating cycle times, manufacturers can lower costs, shorten delivery times and improve quality. Plus, optimizing the machining path of the CNC program and reducing the cycle time before machining also boosts part production and consistency.

Here’s how digital twin tools help:

- Machine simulation. Simulating machining virtually reduces scrap and prototype processing, enhancing productivity.

- Accurate cycle times. Fast CNC simulation improves cycle time estimation accuracy, enabling better production planning.

- Machining optimization. Pre-verification of the machining status helps prevent defects and errors, improving quality and reducing costs.

Integrating CAM and Digital Twin Tools

The CAM process uses CAD designs to generate tool paths for cutting. A postprocessor translates these tool paths into the specific G code required by the machine. However, verifying operations at the postprocessing stage remains a major challenge in creating optimal programs.

Digital twin tools simulate operations with the same accuracy as the actual machine, enabling confirmation of machining paths and cycle times in advanced. This reduces uncertainty and enhances both quality and efficiency.

FANUC offers the following five such digitalization tools for CNC machine shops and machine tool builders:

At IMTS 2024, the company paired its CNC Guide 2 simulation software with a digital twin of a Robodrill VMC at the show for real-time digital machining demonstrations. Source: Evan Doran, MMS

CNC Guide 2. This tool enables virtual simulation at the design stage to predict and prevent machining issues, improving accuracy and reducing machining risk without using a physical CNC machine. By importing real machine data such as the frequency response and friction models captured, the resulting simulation accurately reproduces a real mechanical system. Because CNC Guide 2 includes all the actual FANUC control algorithms, its output reflects the parameterization and tuning of a real CNC.

CNC Reflection Studio. Simulations via CNC Guide 2 and CNC Reflection Studio verify part programs and machining processes virtually, reducing errors and potential collisions. The process creates digital twin machines to simulate and check CNC programs and real-world machining processes. Running an unverified G-code program can result in a costly mistake, and even a properly written program can still cause a machine collision. But testing a new part program in CNC Reflection Studio can safely and quickly prove out the machining process before touching an actual CNC machine.

Surface Estimation. This surface quality check tool replicates real-world surface finish results in digital simulations to accurately check not only the part shape but also machining quality. Prior to any real-world cutting, the software precisely estimates a part’s machined surface by using the position data of each axis then simulating the cutting to detect machining issues. It displays the machining status such as tool speed, tool acceleration and path errors via differentiating colors on the machined surface. Knowing this before cutting helps avoid wasting valuable time and materials that otherwise might be produced with marks or other surface defects.

Tool Path Optimizer. This tool can also help improve part surface quality. Tool Path Optimizer uses CAD data to adjust the tool path in a machining program to create a higher quality finish and part produced. In traditional CAD/CAM workflows, the CAM converts freeform surfaces to small linear movements, which can cause dents and scratches in curved surfaces as well as inconsistent edges. Tool Path Optimizer automatically fixes these curved surfaces by shrinking the distances between command points to create a precision tool path along the designed shape. Optimizing the command points results in better surface quality.

Smart Digital Twin Manager. Offering data integration and management, this tool enables users to keep track of all digital twin manufacturing workflow changes and processes. Files can be fed in from the user’s software to enable side-by-side data analysis such as varying part programs, settings and functions.

Digital tools that transform traditional manufacturing processes have the potential to make operations more efficient by validating production processes in a virtual environment. As demand grows for highly accurate, premium-quality components, machines capable of producing more complex parts with tighter tolerances will become increasingly important. Efficient processes will be critical to meeting these evolving needs. FANUC says that with its Smart Digital Twin Tools, CNC machine shops, as well as machine tool builders, can embrace digitalization to improve manufacturing now and into the future.

Related Content

Avoid the 7 Deadly Sins of Manufacturing

Identifying and preventing these manufacturing sins will reduce or eliminate unnecessary waste, improve efficiency and productivity as well as protect profitability and cash flow.

Read MoreStandard Control Functions with Swiss-Types in Mind

Features in this line of machine-specific CNCs assist setups, offer synchronized movement commands and provide other standard, not optional, capabilities to streamline Swiss-type programming.

Read MoreWho Are the DFM Consultants? You Are.

Modern shops are bolstering their engineering staff to better offer design for manufacturability advice to their customers. Here, one industry expert suggests ways to develop a common language between manufacturing and engineering.

Read MorePrecision Machining Technology Review: April 2025

Production Machining’s April 2025 technology showcase includes some of the latest technology from Sumitomo, Hurco, Supertec, SMW Autoblok, SW North America and Tungaloy.

Read MoreRead Next

Finding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreHow To (Better) Make a Micrometer

How does an inspection equipment manufacturer organize its factory floor? Join us as we explore the continuous improvement strategies and culture shifts The L.S. Starrett Co. is implementing across the over 500,000 square feet of its Athol, Massachusetts, headquarters.

Read More