Manufacturing Scheduling System Focuses on the Now

Improving on-time delivery can happen by prioritizing what needs to happen first, not what job is due first. Among other capabilities, the Production Flow Manufacturing concept can identify situations in which a job with a later due date is actually more urgent.

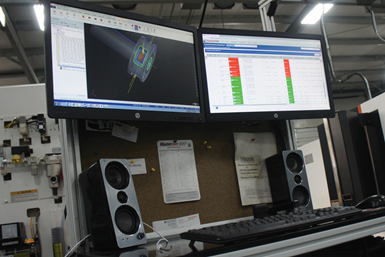

Shopfloor kiosks can provide an interface with LillyWorks’ Production Flow Manufacturing concept. Focused on real-time priorities, this system pulls job data from ERP software and, as seen in the right-hand monitor, outputs the job order that will keep the most work on time. From there, predictive analytics facilitate planning and improvement. Source: MMS

Can focusing on the now rather than adhering to a predetermined manufacturing plan improve throughput, allow for variation and lay a strong foundation for predictive analysis?

LillyWorks says its Production Flow Manufacturing (PFM) concept can achieve these and other benefits for CNC machine shops. That’s because PFM differs from traditional finite scheduling systems in that it is not truly a scheduling system. Rather, it focuses on real-time, shopfloor priorities. Whereas a traditional scheduling model focuses on first generating a plan (the production-scheduling Gantt chart), PFM emphasizes execution. That is, ensuring everyone in production has the visibility of what they should (and can) be working on at the moment. Planning then comes after the shop is executing in the best way possible.

PFM sets and adjusts shopfloor priorities based on the “threat levels” it calculates for every job. Threat levels indicate the relative risk of jobs being late. They are calculated by dividing the percentage of work remaining for the job by the percentage of the job’s remaining “buffer.” Buffers are extra time built into the process to protect the due date — essentially the same concept as starting one’s commute earlier to account for traffic.

The passage of time eats away at the buffers, elevating threat levels. An unexpected delay on one job might raise its threat level even higher. As a result, that job’s operations could move ahead of those associated with other work on a shop’s task lists when the PFM system periodically updates. In contrast, if a job goes smoother than expected, the amount of work remaining declines faster than the buffer, so its threat level drops.

The results of the “Predictor” look like a schedule, but shopfloor priorities have already been set by the time the system runs. As shown here, it outputs which operations will occupy which workstations and when based on how job threat levels will shift in the future. Among other benefits, these projections help identify bottlenecks and confidently answer customers’ questions about when orders will arrive. Source: LillyWorks

This methodology allows for situations in which a job with a later due date is actually more urgent. Consider an example in which a presumed quick and easy job becomes increasingly delayed because an outside plating vendor gets busy and the turnaround date back to the shop stretches longer than expected. As time passes, the buffer shrinks, the threat level rises and the job moves ahead in the priority list. When there is no time left to wait, and the work begins, the necessary capacity is sure to be available. After all, lower threat levels keep less urgent jobs off the shop floor, regardless of their due dates. Later release also ensures these parts spend less time in storage before they ship.

As depicted in this screenshot, PFM prioritizes at the level of the individual workstation. Priorities can also be viewed for all shop resources at once, or any subset of workcenters, including specific machines, groups of machines as well as people required to run the machines Source: LillyWorks

The buffer for the overall job is the sum of the buffers for each workstation it crosses. As opposed to trying to buffer each individual operation, PFM uses a shared buffer to absorb variation throughout the life of the order. The goal of refining buffers is to ensure jobs are released to the shop early enough to meet delivery dates, but late enough to prevent sending too much work into the shop creating work in process (WIP). Sending too much work into production slows workflow, confuses true priorities and creates long leadtimes. Having less WIP means that whatever jobs are in WIP will flow through their respective operations as fast as possible, shrinking production lead times and increasing on-time delivery and throughput.

One of PFM’s fundamental concepts might be puzzling for those who have worked with the traditional method of scheduling: that is, by design and on purpose, PFM’s prioritization method is blind to the shop’s capacity. It doesn’t matter if the shop has three machines or 300, two shopfloor employees or 200. Of course, understanding current and future production capacity is essential for any manufacturer. But the way PFM provides this future visibility is simply by simulating how production will be executing priorities into the future based on how many hours each department works, the number of machines and/or people in each department and even material availability. The result is a believable view of the shop’s future production reality showing predicted start and finish dates of each operation of each job, where/when bottlenecks will be and load versus capacity.

This enables sales, production and other departments to be able to answer key questions. When can customers expect to receive their orders? What will be our biggest bottleneck resource preventing on-time delivery? What is the projected load versus capacity of machines and people into the future?

This believable future production reality lays the foundation of being able to get solid answers to “what-ifs.” Can a job be expedited without delaying other work? How well can a shop accommodate additional work in general? What would be the impact of adding another machine tool or perhaps another shift? When would we be able to get this job quote out without impacting any other jobs? Or, if we are willing to bump other jobs, what would be the impact of setting an aggressive due date to that quote?

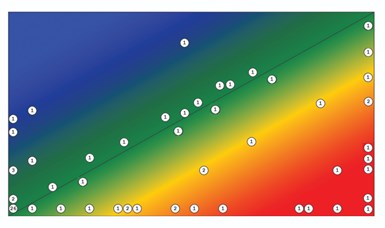

Snapshots like this, in which jobs are arranged according to their percentage of work (vertical axis) and percentage of buffer (horizontal axis) provide an at-a-glance view of where jobs are now, and which are in danger of being late. Source: LillyWorks

PFM’s predictive analysis capability comes in the form of a software tool called the “Predictor.” The Predictor uses PFM threat-level information along with inventory, capacity and other ERP data to project what workflow will look like for however far out into the future a shop has production orders. Essentially, it simulates the execution of the shop’s entire backlog to predict when every operation for every job will start and finish. The intent is to conduct “what-if” scenarios. For example, to determine what to quote when, to find and break bottlenecks, to refine buffers and other metrics, or to conduct any other analyses required to improve throughput and on-time delivery.

PFM methodology allows for situations when a job with a later due date is actually more urgent to complete.

The result looks much like a schedule, such as the ones generated by traditional capacity-loading algorithms. The difference is that shopfloor priorities have already been set by the time the Predictor runs. There is no question about, say, why one job’s changing threat level pushed it ahead of the other because the simulation matches the reality of how work orders will flow through the shop, barring any buffer changes or process refinements. Because the data matches the reality, it provides a better foundation for machine learning.

Advancements to the PFM concept continue. New aspects of LillyWorks’ technology include a new Capable to Promise (CTP) feature that enables a user to get a fast answer, in seconds, to the question: “When could I get this new order/quote out without impacting any of my existing production orders?” without having to run the complete simulation. (Generally, a complete simulation run will take approximately five minutes per 100 workorders a shop has in production.) Lillyworks also released a new “Outside Services Execution” workstation that shows priorities and complete status of any outsourced operations, such as heat treating, galvanizing, plating and so on. Lillyworks also is exploring artificial intelligence applications to further refine both threat level determination and buffer sizing characteristics to help manufactures get even more benefits from the PFM method of managing production.

Related Content

Precision Machining Technology Review: December 2025

Production Machining’s December 2025 technology showcase includes some of the latest technology from Grob Systems Inc., Seco Tools, Horn USA Inc., Tungaloy-NTK America Inc. and Datanomix.

Read MorePaperless Parts' AI-Powered Automation Tool Streamlines Quoting

Wingman is powered by a secure AI model developed to extract critical information from quote packages so that estimators can work faster, automate administrative aspects of setting up quotes and minimize the risk of missing important details.

Read MoreShopGuru Software Supports Organized CNC Machine Operations

IMTS 2024: ShopGuru’s digital work instruction software offers a robust, secure solution that can enhance machining efficiency and accuracy.

Read MoreHack-Proof Your Shop: Production Machining’s 6 Must-Read Cybersecurity Articles

October is cybersecurity awareness month and Production Machining wants to help you make your shop hack-proof.

Read MoreRead Next

How To (Better) Make a Micrometer

How does an inspection equipment manufacturer organize its factory floor? Join us as we explore the continuous improvement strategies and culture shifts The L.S. Starrett Co. is implementing across the over 500,000 square feet of its Athol, Massachusetts, headquarters.

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read More