Imagine this scenario on the production line: A turning center is running a batch of parts from an exotic, expensive alloy barstock. Each part requires 5 inches of material, which, at the end of the bar, leaves a 4-inch remnant. It’s not enough to make another 5-inch part, but it would be expensive to waste the length of barstock.

Obviously, the machine operator could reprogram the lathe and bar feeder to make a different part from the remaining material, but that would interrupt the production schedule, and the operator time involved would be counterproductive. Wouldn’t it be great if the turning machine and bar feeder could figure out how to make a good part out of that costly piece of metal without requiring additional operator time? Well, now it’s possible.

Bar feeder manufacturer

LNS has developed a database and data transfer system that enables a turning machine and bar feeder to share realtime information. This capability means that, among other things, the bar feeder and turning machine can analyze material usage, and then the turning machine can search the production schedule, find another part that can be made from the remaining material and change a part program on the fly. Whether the job is made from an expensive alloy or more conventional barstock, material waste and labor costs can be reduced while making the production process more efficient.

Connects Part Programs and Production Schedule

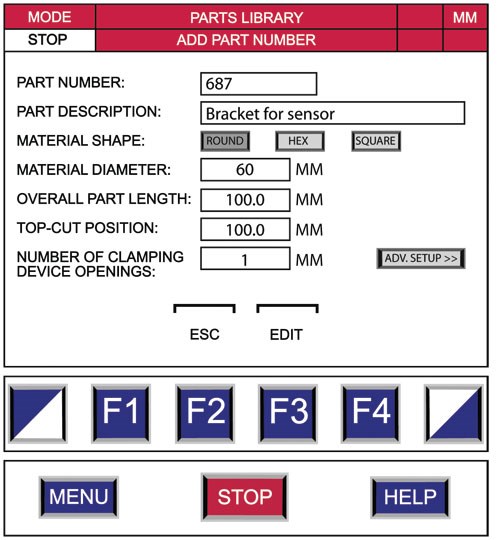

Developed in cooperation with major turning machine tool builders and with extensive input from end users, the system enables manufacturers to create a library of more than 1,000 part programs that are stored in the bar feeder’s programmable logic controller (PLC). Each part program in the library has a unique identifying number and contains all of the production parameters required by the bar feeder for that specific part.

Using these part programs, the manufacturer can develop a production schedule as simple or complex as desired. Because the system allows for a lot of flexibility, users can design the production schedule to maximize efficiencies in virtually all applications.

Once the operator initiates production with this schedule, the bar feeder continuously tracks material usage, informing the turning machine about how much stock is available. Using the earlier example, let’s say the turning machine recognizes that the 4 inches of material remaining is not sufficient to produce one more of the part it has been running—we’ll call it part No. 123. The turning machine, now aware of how much material remains, scans the parts scheduler to determine if there is another part in the queue that can be made from this 4-inch piece of barstock.

According to the scheduler, part No. 678 is a viable match. Now the turning machine sends the part number to the bar feeder, which scans the parts library to locate a match. Finding one, the bar feeder downloads the parameters for part No. 678 and makes these the current settings by automatically adjusting such factors as part length and top cut position. All of these adjustments are performed automatically on select LNS bar feeder models. As a result, the machine tool can move seamlessly from one job to another without operator assistance.

In this case, the turning machine makes part No. 678, thus using the 4 inches of remaining barstock that otherwise may have become scrap. Now the turning machine will check the schedule to determine whether to continue making the original part (No. 123) or move on to another part program.

All of these communications between the bar feeder, the turning machine, the production scheduler and the parts library are virtually instantaneous and require no operator assistance. Provided that parts use the same barstock shape and diameter, the scheduler is capable of efficiently completing an infinite mix of long or short production runs, a complex family of parts and even a variety of unrelated parts. Clearly, these capabilities contribute a substantial savings of time, labor and material.

Recognizing Priorities

The system design takes into account that some production schedulers may wish to develop more complex agendas including such advanced functions as prioritizing part programs. In such a case, if the turning center’s production scheduling program contains more than one part that can be made from remaining material, the scheduler selects the appropriate part program based on the variables built into the schedule.

Typically, the scheduler assigns priorities to like size parts, based on needs. The scheduler will follow these directives and download the part program with the highest priority from the library, based on the remaining barstock length. Because the scheduler can also track how many of each part is made, it knows whether or not there is still a need for the first priority part. If not, the scheduler will bypass that part and move on to the next highest priority. It will continue working through the schedule in this way until it finds the next available part.

Advanced Ethernet Connectivity

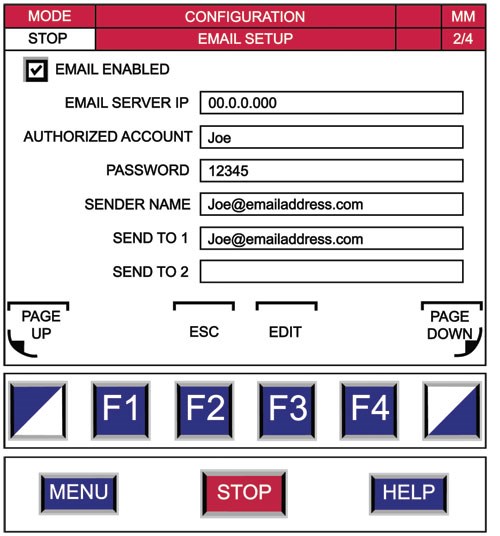

With Ethernet connectivity, the cost saving possibilities are even more impressive. The bar feeder can use an Ethernet connection to establish remote communications. With the push of a button, an e-mail of the parts library can be sent to any designated e-mail account. This means the parts programmer, production manager or any other individual within the company granted permission, can remotely analyze the parts library and make changes.

If a program needs to be added or deleted from another area of the building or even from a different facility in another town or country, as long as there is Internet access, it’s no problem.

Another advantage is that if a bar feeder alarm occurs, the system can automatically e-mail the fault notification to one or several designated e-mail accounts for realtime analysis and support. This communication method can be more efficient than using phone or fax, which can lead to misunderstandings, transposing numbers and other errors.

E-mailing precise information to offsite experts may reduce machine downtime and save travel time and expense. These data can provide the LNS support team a clear picture of the current situation, which may allow it to troubleshoot and suggest remedies on the spot. Plus, if a service technician must visit the shop, this information allows the technician to be better prepared. Equally important, e-mail notification means the operator or production supervisor will know instantly when someone needs to check the production line. This can be especially valuable when running untended.

More to Come

Currently in use with select turning machines, the system will soon be more available. LNS continues to listen to OEMs and end users, and their needs will drive the development of other useful enhancements. Soon, users will have the ability to receive notifications in alternative communications formats, such as text messages.