Robots as Precision Machine Tools

To remain competitive, high-end manufacturing companies are looking for accurate, reliable and maintenance-free machine tools offering fast change-over, programming and setup. Industrial robot technology could provide an excellent base for machining because it is flexible and affordable.

COMET (Plug-and-produce Components and Methods for adaptive control of industrial robots enabling cost effective, high precision manufacturing in factories of the future), co-funded by the EU, is creating a solution that enables the use of industrial robots for high-end machining. Robots of any brand fitted with the plug-and-produce controller unit can respond to manufacturing industry needs for cost effective, flexible and reliable manufacturing solutions.

Nikon Metrology is a primary contractor for the program, developing an adaptive tracking system to detect deviations from the programmed robot path. This system is used to initiate real-time toolpath corrections to maintain the targeted accuracy throughout the entire machining sequence. The proposed COMET solution is estimated to be, on average, 30 percent more cost effective than dedicated machine tools, while delivering absolute positional accuracy better than 50 micron.

Industrial Robots

To remain competitive, high-end manufacturing companies are looking for accurate, reliable and maintenance-free machine tools offering fast change-over, programming and setup. Industrial robot technology could provide an excellent base for machining because it is flexible and affordable.

Combined with enabling metrology solutions, industrial robots offer distinct advantages over specialty equipment designed for specific machining tasks. As part of the COMET project, Nikon Metrology is responsible for developing an adaptive tracking system. The system helps adjust real-time robot arm positioning in relation to where it should be according to the initial programmed robot path.

The adaptive tracking system tracks the location of the robot head in real-time and feeds back the metrology data using a closed feedback loop via the controller. This metrology-adjusted process substantially increases robot accuracy because it almost eliminates the influence of robot warm-up, drift and backlash. It underlines the importance of the adaptive tracking system in transforming industrial robots into precision tools for milling, deburring and other machining applications. Such robots are in high demand in aerospace and automotive markets as well as manufacturing environments involved with mold and die and high-precision parts.

Real-Time Robot Motion Adjustment

The plug-and-produce robot control system is a modular system that fits most robot brands, including ABB, Fanuc and KUKA. Other modules that can be plugged in focus on kinematic and dynamic models to set up a unique robot fingerprint, a holistic programming and simulation environment and a high dynamics compensation mechanism to eliminate remaining positional errors.

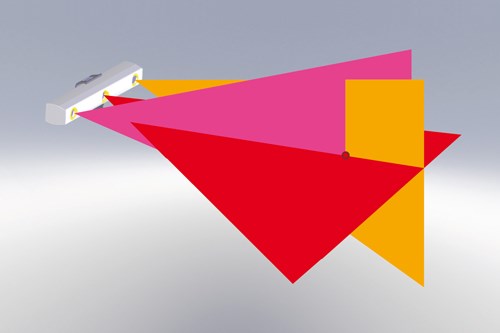

The adaptive tracking system module consists of two components: the tracking system and the comparison and path adaptation module. Based on specific project needs, the tracking system research will start with the K-Series optical CMM from Nikon Metrology.

The K-Series pre-calibrated solid state camera system consists of three linear, built-in, charge coupled device (CCD) cameras. With cylindrical lenses on all cameras and the middle camera tilted 90 degrees, the optical CMM measures the locations of infrared light emitting diodes (LEDs) mounted on the robot head. As an LED is located where the 3 CCD observatory planes intersect at the instance of capture, the system is able to determine the point coordinates based on the plane inclination angles. The system offers the means to track multiple LEDs simultaneously with 6 degrees of freedom at a sample rate of as much as 1,000 Hertz to allow for dynamic measurements.

The module for the corrective adaptation continuously compares the measured position, speed and acceleration with the corresponding data in the part program. A model-based algorithm then determines when and how to adjust robot operation to meet the accuracy required by the machining process. Development efforts from Nikon Metrology engineers concentrate on measuring accuracy, system latency and module interfacing to obtain precise and prompt robot motion adaptations.

Ready to Go

The flexibility and cost efficiency of industrial robots is used by adding absolute position accuracy and a plug-and-produce software environment to design, program, simulate and execute high-end machining processes. New, innovative tracking components and modular ICT-based methods are being developed to open new application areas for industrial robots. These components and methods can be plugged into the modular platform, ready for use with any industrial robot cell.

The 30-month COMET project was kicked off in September 2010. After completing the plug-and-produce robot controller, Nikon Metrology will act as a partner in exploiting the project results. The project involves 14 technical partners from eight countries across Europe, coordinated by manufacturing software specialist Delcam.

Related Content

A Tale About an Automation Solution Discovered in Production Machining

A CNC Swiss production supervisor took to LinkedIn to describe how he discovered a rotary parts collector in the pages of our publication and has since purchased and benefited from it.

Read MoreRobotic Machine-Tending Ideas for Production Shops

Here are five examples of how machine shops have benefited in various ways by adding robots to tend machine tools.

Read MoreAutomation Idea for Halloween?

Maybe not. But, the candy-throwing robots at MetalQuest’s Nebraska facility do enable the contract machine shop to stand out at career fairs and similar events.

Read MoreThe Advantages of Automated Shopfloor Gaging

This “parallel kinematic” gage offers the opportunity to automate and improve machining process control for shops endeavoring to move from sample inspection to 100% inspection.

Read MoreRead Next

Handling Parts In A Robotic Cell

Here’s a review of the workholding and workhandling challenges a shop faces as it moves a part through a robotic cell, from serving up the blanks to the transfer of the final workpiece to post processing and gaging. Productivity, Inc. takes the reader through a few of their cells that they've installed using Fanuc robots and a variety of other machine tool equipment.

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreHow To (Better) Make a Micrometer

How does an inspection equipment manufacturer organize its factory floor? Join us as we explore the continuous improvement strategies and culture shifts The L.S. Starrett Co. is implementing across the over 500,000 square feet of its Athol, Massachusetts, headquarters.

Read More