Six are Good, Eight are Better

At the recently completed EMO Hannover, the multi-spindle builder Index, headquartered in Esslingen, Germany, unveiled its new eight-spindle, CNC automatic production lathe.

At the recently completed EMO Hannover, the multi-spindle builder Index, headquartered in Esslingen, Germany, unveiled its new eight-spindle, CNC automatic production lathe. This is the first eight-spindle the company has produced.

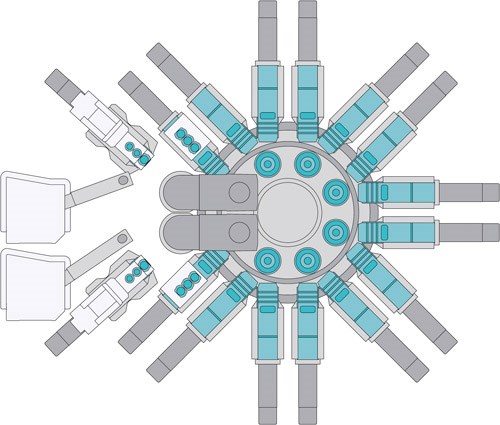

The machine is built on using the company’s multi-spindle modular system designed for production of highly complex workpieces. The idea of multi-spindle production machines is to divide the various operations performed on a workpiece across multiple spindles, enabling simultaneous machining instead of sequential operations.

With the advent of the MS22-8, Index is able to offer even more production flexibility across this multi-spindle for more complex parts. It also provides the opportunity, when so equipped, to perform “double drop” production where two parts are machined in each cycle, which was demonstrated in the booth at EMO (more about that later).

Each of the eight symmetrically arranged spindles is assigned two cross slides, which can travel both on the X as well as on the Z axis for a total of 16. Each cross-slide can be additionally equipped with a Y axis. In addition to the linear axes, as many as two swiveling synchronous spindles are available for simultaneous rear end machining.

Using integral direct-drive spindle motors, the rotational speed of each of the eight spindles can be controlled separately. The spindle drum is fluid cooled to keep the thermal growth in the spindle carrier to a minimum. This is a change from Index’s previous air cooled spindle drum design.

The advantage compared with the previous air-cooling approach is the higher power density in the spindle drum and the capability of energy recovery from the heated cooling fluid. In addition, the spindle bearing temperature can be kept at a low level, which also prolongs its service life and improves thermal stability.

The cross slides with integrated drive have a low-mass design with hydrostatic bearing support. They are appealing because of their low moment of inertia and the resulting high dynamics, which facilitates outstanding acceleration in a practical application.

The advantage of a hydrostatic sliding guide in the feed axis (Z) is its outstanding damping characteristic that prevents the transfer of the machining vibrations to the adjacent slide via the headstock. This helps to mitigate chatter while workpieces are being machined, even when the most diverse machining processes are being performed concurrently by the eight spindles.

One spindle can be used for heavy-duty roughing while high-precision finishing takes place on another spindle without sacrificing surface quality. In addition, the hydrostatic bearing is wear-free: There is neither friction nor a stick-slip effect.

Another of the machine’s highlights is its double workpiece rear-end machining capability, which is achieved using swiveling synchronous spindles that are locked into the end positions by three-part Hirth couplings. The high level of stiffness that this achieves also guarantees that even with bar diameters up to 24 mm, rear end machining operations with very high cutting volumes and simultaneously high machining precision can be performed.

The swiveling synchronous spindles stand out because of their outstanding dynamics: The swivel movement to the rear end position occurs in less than 0.3 second. The advantage of the three-part Hirth coupling is that it is no longer necessary to electronically compensate at the end position. The mechanical lock ensures optimal stiffness and increases the positioning accuracy. This allows even highly complex components to be produced that require complex cut-off side machining.

The standard version of the machine, the Index MSC-8, already offers diverse and numerous applications: It can be operated as an eight-spindle machine, as a double four-spindle machine or as a machine with double rear-end capability. As a result of double four-spindle machining, two finished parts are produced by the machine per work cycle.

However, the new MSC-8 in double four-spindle mode actually runs as two machines working with one another simultaneously on a single platform. Every second tool station always has simultaneous access to the same tools.

In double rear end machining, there are six spindle positions available for front machining the workpiece and two spindle positions for rear end machining, and they all work simultaneously. With this approach, it is possible to machine the rear end of a workpiece during two drum indexing cycles.

The new Index eight-spindle multi-spindle has many applications throughout all industries, ranging from the automobile industry to medical technology. It also produces small batches efficiently and economically.

Another benefit for the user is that all standard toolholders and toolholder system interfaces can be used with the appropriate adapters (Capto, HSK, VDI, Index systems).

The machine can be configured to cater to current market demands that dictate that workpieces be discharged damage-free from the work area. Machine-integrated handling with an external stacking unit ensures both destruction-free removal of parts from the machine—with connected (auto-feedback) measuring operations for the workpieces, if needed.

Related Content

Precision Machining Technology Review: February 2025

Production Machining’s February 2025 technology showcase includes some of the latest technology from Marubeni Citizren-Cincom, Murata Machinery USA, Mazak, Star CNC, Grob Systems and Schütte.

Read MoreVideo: Using AR for Remote Machine Tool Troubleshooting

Augmented reality can enable service engineers to help machine shops identify and possibly remedy issues with their machines remotely, perhaps eliminating the time and cost of an on-site diagnostic and maintenance visit.

Read MoreMazak CNC Turning Center Enhances High-Volume Production

Mazak Corp.’s QRX-50MSY turning center is a compact and versatile machine designed for small, intricate parts with advanced milling and Y-axis capabilities.

Read MoreMethods Multitasking Machine Reduces Cycle Times

Methods Machine Tools Inc. introduces Nakamura-Tome’s WY-100V two-turret, twin-spindle precision CNC multitasking lathe to the U.S. market.

Read MoreRead Next

How To (Better) Make a Micrometer

How does an inspection equipment manufacturer organize its factory floor? Join us as we explore the continuous improvement strategies and culture shifts The L.S. Starrett Co. is implementing across the over 500,000 square feet of its Athol, Massachusetts, headquarters.

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read More