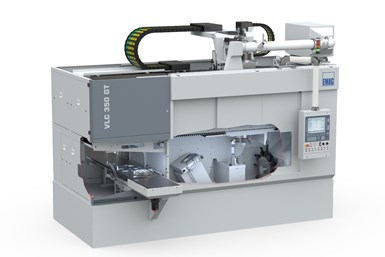

Automated Hard Turning, Grinding on One Platform

This inverted vertical turning machine can perform hard turning and grinding of chucked components such as gears while loading and unloading material and completed parts itself.

This combined hard-turning/grinding machine is available with an internal grinding spindle mounted on a B axis to enable tapers to be ground.

Photo Credit: All photos courtesy of Emag LLCThe inverted vertical turning machine platform has been offered by Emag since 1992 with its VSC 250. This design is unique in that the spindle is able to load and unload parts itself. In a sense, it serves as its own robot.

Since then, the company has expanded its offerings creating modular designs that can be customized per a specific application. Its latest is the VLC 350 GT which is designed to perform hard turning and grinding of chucked components, especially for transmission and engine production applications. This enables parts such as gears to be completed in one setup.

The machine chucks components ranging up to 350 mm in diameter, performing turning and grinding processes progressively in a single clamping. The VLC 350 GT enables traditional hard machining of gears, from hard turning of end faces and pre-turning of the bored holes and outer synchronizing taper through to finish grinding of those contours.

The internal grinding spindle with NC swiveling B axis allows for processing of components with internal tapers. The operations for a typical component with an internal taper include:

- Loading (and subsequent unloading) with a pickup spindle followed by hard turning of the end faces.

- Depending on the component geometry, inner contours (with one or two tapers), a cylindrical bored hole and the outer synchronizing taper can be pre-turned in the second step.

- The use of a cylindrical grinding element on the swiveling NC axis next makes it possible to machine various internal taper angles. To do this, the grinding spindle is swiveled precisely to the required angle for the specific case. Any required bored holes are also completed this way (with a zero-degree grinding angle).

- The final step is the grinding of the outer synchronizing taper with the external grinding spindle.

An external grinding spindle with integrated balancing system can be mounted straight or at an angle and can accept a grinding wheel measuring 400 mm in diameter.

Parts can be presented to the spindle at the pickup station via a conveyor belt or shuttle system. The spindle, which moves by way of an X-axis cross slide, then delivers the part to the machining area. A tool turret can be fitted with live tooling to perform drilling or milling operations. An available internal grinding spindle uses an HSK interface, while an available external grinding spindle with integrated balancing system can be mounted straight or at an angle and can accept a grinding wheel measuring 400 mm in diameter. Wheel reconditioning is performed using a rotary diamond dresser. A part gaging system is located outside the machining area to protect it from coolant and chips.

The VLC 350 GT is available in a variety of configurations. This includes one internal grinding spindle and a turret; two internal grinding spindles and a turret; one external grinding spindle and two internal grinding spindles; one external grinding spindle and a turret; and a honing unit, internal grinding spindle and turret.

For process control, this machine includes acoustic sensors for the grinding wheel and the dressing wheel. For the latter, this is especially helpful when dressing cubic boron nitride (CBN) and other very hard wheel materials to limit the amount of costly material removed during dressing.

Additional information and component application examples are found at gbm.media/emagvtl.

Related Content

5 Tips for Multichannel Programming

Programming for multitasking machines can be complex. Knowing several key points for making the process less challenging can save a programmer time as well as lessen confusion and the risk of error.

Read MoreVideo: The Value of a Desktop CNC Swiss-Type

This Swiss-type requires only 120 volts of power, basic compressed air supply, weighs in at 150 pounds and needs a table that’s only maybe two by four feet. But it’s by no means a toy.

Read MoreBridging the Gap Between Traditional Single- and Multi-Spindles

This twin-spindle automatic lathe with six cross-slide mounted turrets is designed for medium-sized production runs that might not be suitable for conventional multi-spindles.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreRead Next

Finding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreHow To (Better) Make a Micrometer

How does an inspection equipment manufacturer organize its factory floor? Join us as we explore the continuous improvement strategies and culture shifts The L.S. Starrett Co. is implementing across the over 500,000 square feet of its Athol, Massachusetts, headquarters.

Read More