Electrochemical Grinding Makes a Point

A programmable pointing and material handling system used on electrochemical grinding machines can accommodate a range of needle point designs while eliminating a variety of pre- and post-process operations.

According to electrochemical grinding (ECG) solutions provider Tridex Technology, a part of Glebar Company, grinding sharp points onto needles used in surgical procedures can be challenging using conventional methods. Oftentimes, the needles must be masked for handling, requiring additional steps in the production process. Many manufacturers also still use converted outer diameter (OD) grinders with custom tooling and soft grinding wheels, which can wear at a high rate. Setting up and changing over these machines can be time consuming and require extensive mechanical adjustments. In addition, once in production, these grinders leave a large inner diameter (ID) burr, requiring the needles to be sent through a secondary process such as grit blasting or electropolishing. Plus, complex needle points, such as Menghini points, require a separate primary bevel cut and secondary sharpening, which can lead to longer cycle times.

Tridex says some custom machine builders have developed needle grinders using robots to replace or simplify the fixturing. However, a robotically controlled fixture requires a series of collets to clamp and rotate the needles in unison. Collet systems take up a lot of space and this limits the number of parts that can be sharpened to a set amount (usually no more than 20 at a time). The company says another limitation of a robotic fixture is that the needles must be held far from the grinding wheel, which can lead to deflection and grinding inaccuracy.

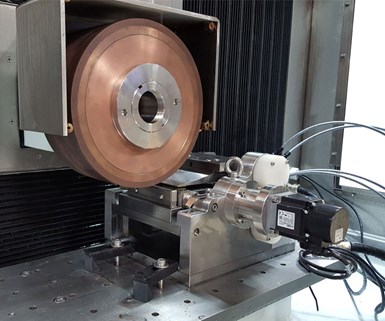

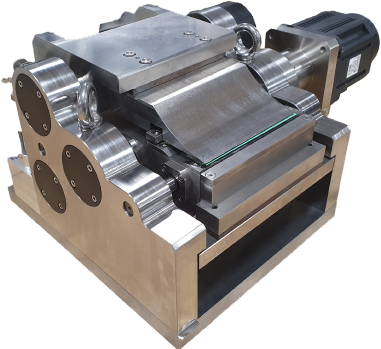

Electrochemical grinding using a programmable pointing and material handling system can accommodate a range of needle point designs while eliminating a variety of pre- and post-process operation (Photo credits: Glebar Co.)

As an alternative, Tridex has developed its PGS-100 burr-free ECG point grinding system, which can be installed on its SG-1645 and SG-2060 ECG machines. The goal was to develop an accurate grinding process that would eliminate masking, pre- and post-processing, and deflection while enabling quick setups and changeovers as well as handling a variety of needle point designs. ECG flows electrical current from a negatively charged abrasive wheel to a positively charged conductive workpiece through an electrolyte. The metal is removed with very little heat, both by mechanical abrasive action and electrochemical dissolution.

This PGS-100 can be used on two Tridex ECG models. Compared to conventional fixturing methods, it is said to offer higher point grinding accuracy and minimal deflection.

Made from stainless steel, the PGS-100 is a fully programmable ECG pointing and material handling system for tube or solid wire. Its servo-controlled design is said to offer precision needle rotation and repeatability, and its simplicity in loading and unloading enables trained operators to run multiple machines at once. It can produce any number of facets on needles measuring in diameter from 0.013" to 0.2", including tri-bevel, back-bevel, diamond-point, trocar, stylet, Franseen, Menghini and custom points. It is also capable of handling 4" (100 mm) width of workpieces holding between 32 to 120 needles, depending on their diameter, which enables manufacturers to maximize their output per cycle. By clamping the needles closer to the point, the PGS-100 is said to achieve higher point grinding accuracy and minimal deflection. Secondary operations, such as burr-free, cross-slot grinding and notch cuts for biopsy needles, are also possible.

Related Content

Shop Optimizes its Swiss-Turning Flexibility

Paramount Machine uses various Swiss-type lathes, some with a B axis, to produce parts more effectively than it did on conventional chucker lathes. Today, nearly every job under 1.5 inches in diameter runs across those machines even if the batch size is a mere 5 pieces.

Read MoreAutomation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

Read MoreStuder Universal Cylindrical Grinding Machine Streamlines Performance

Studer’s FavoritCNC universal cylindrical grinding machine has been further developed to feature modern grinding technology with high-precision, simple operation at a cost-effective price point.

Read MoreTaking the Complexity out of Swiss Machining

How machine shops become more efficient with offline CAM programming, featuring toolpath generation, built-in simulation, multichannel control, proven postprocessors and seamless Solidworks integration.

Read MoreRead Next

Using Grinding Versus EDM to Finish Form Tools

Finishing carbide inserts using EDM or grinding.

Read MoreBond Selection for Production Grinding

Proper grinding wheel selection is essential to ensure that the required part quality, production rate, and overall cost per part is achieved. Although the type of abrasive grain is often a primary driver of wheel selection, the bonding type can also play a key role in optimizing a grinding operation.

Read MoreHow To (Better) Make a Micrometer

How does an inspection equipment manufacturer organize its factory floor? Join us as we explore the continuous improvement strategies and culture shifts The L.S. Starrett Co. is implementing across the over 500,000 square feet of its Athol, Massachusetts, headquarters.

Read More