Precision Doesn’t Necessarily Mean ‘Tiny’

At Keystone, the operators roll the thread form onto the material, which makes for a stronger thread.

The team at PMPA member Keystone Threaded Products (Valley View, Ohio) shows us that “precision” doesn’t necessarily mean “tiny” as the company threads the ends of 20-foot long, 10-inch stainless steel bars for a metalworking press. The thread is 10 ¼ inch: 4 UNJ RH applied to each end of the 3 ½-ton bar.

20-feet long, two ends to thread, 3 1/2 tons of precision

At Keystone, the operators roll the thread form onto the material, which makes for a stronger thread. Alignment and following the process is critical to assure a good thread.

Thread rolls create the thread form on the workpiece.

Multiple passes are needed to build up the thread to the proper dimensions.

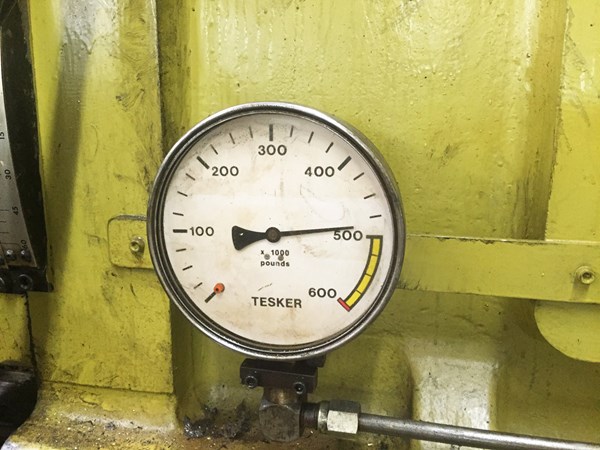

Half a million pounds of pressure are imparted on the rolls to plastically move the steel of the bar into the thread form. Read the gage.

Obviously, it takes knowledge, skills and experience to apply half a million pounds to produce precision work.

Rich says he has rolled larger bars, but skills, experience and a great team to work with create the can-do spirit that makes precision manufacturing a great career.

Here’s another look at a finished bar. Precision does not necessarily mean tiny.