Focusing on the Swiss You Need

These two Swiss machines are designed to offer flexibility at a good price.

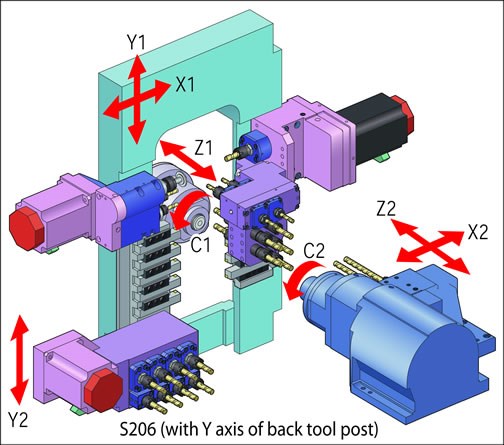

So you’re looking for the latest in Swiss technology, but you need to stay within a limited budget. You work with a range of parts, and you need the flexibility to make adjustments to fit each given application. Rem Sales, LLC recently announced the introduction of two new Tsugami Precision Swiss turns that may fill your need. The new 20-mm models, the Tsugami S205 and Tsugami S206, were designed to provide Swiss technology users the flexibility and capability to meet a range of needs at an affordable price.

"This new ‘S’ platform allows our customers a range of capabilities and enhanced productivity, which will help them differentiate from their competitors,” states Scott Anthony, national sales manager of Rem Sales, the exclusive North American distributor for Tsugami. “The new machines are a natural evolution for them, as many have embraced the concept of flexibility, as demonstrated by the successful introduction of the ‘Super SwissTurn’ SS Series 3 years ago.” The new S205 and S206 models feature a modular tool zone similar to that found in the SS Series and faster (12,000-rpm) spindle speed.

Both machines are suited for the production of complex parts. Live tools for cross and face operations are found on the main and subspindle. A two-path control permits true simultaneous operation of the main and subspindle, dramatically reducing cycle times. The modular tool zone is designed to allow the operator to easily move driven tools from main to subspindle and from face to cross positions, minimizing downtime between different jobs.

The S206 has the same capabilities of the S205, plus backworking Y-axis movement. A Fanuc 31i-A control is standard on both models. The machines can also accommodate an optional "chucker kit" to allow running as a Swiss turn or fixed headstock lathe. The fixed headstock configuration can use unground barstock, eliminating costly bar remnants and improving part concentricity.

Related Content

-

Does a Scanning Probe Make Sense on a Swiss-Type?

Swiss-types have limited tooling capacity, but there can be advantages to giving up some of that capacity to take advantage of a touch probe — in fact, a scanning probe — to enable in-process part measurements.

-

5 Tips for Multichannel Programming

Programming for multitasking machines can be complex. Knowing several key points for making the process less challenging can save a programmer time as well as lessen confusion and the risk of error.

-

When a CNC Turn-Mill Doesn’t Turn

A shop in Big Sky Country uses a B-axis multitasking machine to produce complex, prismatic medical parts that require no turning complete from barstock.