LaserSwiss Combines Styles

The compact, 12-mm, five-axis Swiss-type CNC lathe is the smallest LaserSwiss the company offers.

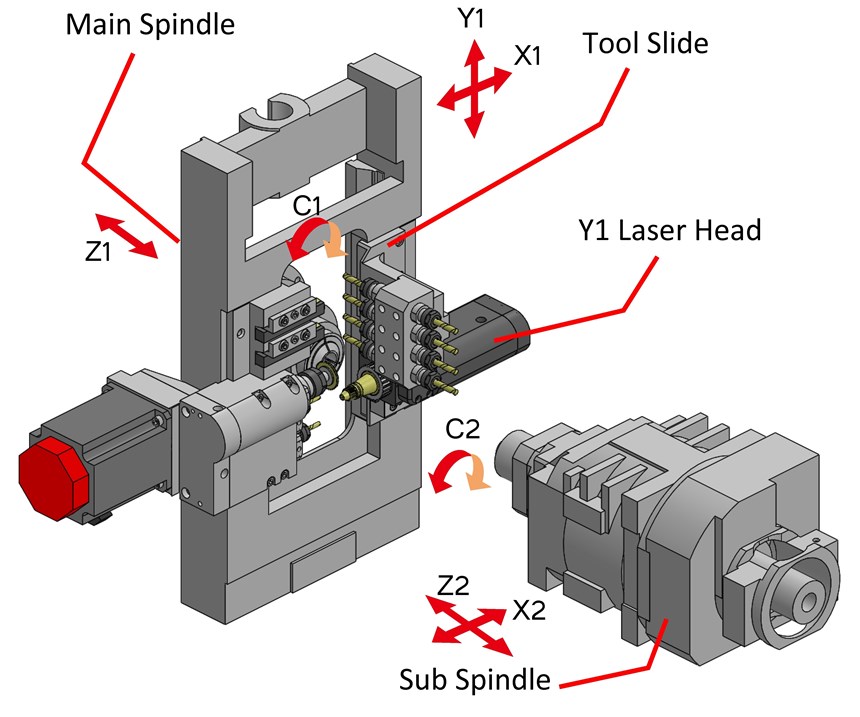

LaserSwiss is a Tsugami B0125-III with a fully integrated laser cutting system. The compact, 12-mm, five-axis Swiss-type CNC lathe is the smallest LaserSwiss the company offers.

According to Business Development Director Dan Walker, the company designed the B0125 LaserSwiss for shops that typically perform tube cutting operations with standard tube cutting machines. In addition to laser tube cutting, the product enables turning operations, such as adding a chamfer without having to move the part to another machine or outsourcing those operations.

The product is the only 12-mm machine on the market that combines Swiss turning and laser cutting within a fully integrated platform, according to the company. It has 10 tool positions in addition to the laser, and it is convertible between a traditional Swiss-typelathe or with an optional chucker kit.

This product also offers an assortment of 20-mm and 32-mm machines with linear axes ranging from three to seven. Available models include B-axis capability and a second laser head for welding. The company says it is giving manufactures machining options so they get precisely what they need. The machines are available with laser watts ranging from 200 W to 500 W. All laser operations are programed and driven from the machine’s FANUC 0iTF control and the laser’s frequency, pulse width, focus and power are on-th-fly adjustable.

Related Content

-

Video: The Value of a Desktop CNC Swiss-Type

This Swiss-type requires only 120 volts of power, basic compressed air supply, weighs in at 150 pounds and needs a table that’s only maybe two by four feet. But it’s by no means a toy.

-

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

-

Keeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.