MachiNetCloud IoT Service Offers Remote Monitoring

The system is designed to enable users from any location to remotely access, analyze and monitor real-time data of machinery connected in an automation cell, quickly and accurately.

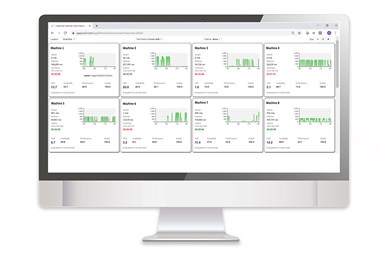

Shibaura machiNetCloud enables users from any location to remotely access, analyze and monitor real-time data of machines connected in an automation cell. Photo Credit: Shibaura Machine

Shibaura Machine’s machiNetCloud is an industrial IoT service providing manufacturers with secure, remote access to real-time machine data any time and from any location, the company says.

Instead of waiting hours or days for a technician to arrive on-site and diagnose problems that must be fixed, authorized users and third-party vendors can monitor machines remotely and access that data in a fraction of the time, enabling them to quickly respond with a technician or spare parts, the company says. Should a problem arise, machiNetCloud automatically alerts third-party technicians and internal users by email and SMS, helping reduce downtime and save on maintenance costs.

It is said one of machiNetCloud’s key features is its intuitive customer portal, providing users with a suite of applications for reviewing key performance indicators showing the operating status of a factory, even in remote locations. The company says it is one of the most dependable, secure methods available for manufacturers to measure and track data, helping them improve their facility’s overall equipment efficiency (OEE).

Another key feature is its ability to automatically capture, analyze and track machine downtime, providing managers with the data they need to better utilize continuous improvement resources in order to maximize OEE and plant productivity. In addition to downtime tracking, the system offers real-time condition monitoring, historical performance and production analytics, applications for managing quality, production recipes and energy, and more.

Related Content

-

Robotic Machine-Tending Ideas for Production Shops

Here are five examples of how machine shops have benefited in various ways by adding robots to tend machine tools.

-

Automation Idea for Halloween?

Maybe not. But, the candy-throwing robots at MetalQuest’s Nebraska facility do enable the contract machine shop to stand out at career fairs and similar events.

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.