Open Mind HyperMill Software Reduces Calculation Time

Open Mind Technologies’ HyperMill 2019.1 CAD/CAM software includes an expanded finishing module in the Maxx Machining Performance package and process optimizations.

Open Mind Technologies’ HyperMill 2019.1 CAD/CAM software includes an expanded finishing module in the Maxx Machining Performance package, process optimizations such as a thread milling module, a function for reducing calculation times, tool database flexibility and CAD optimization.

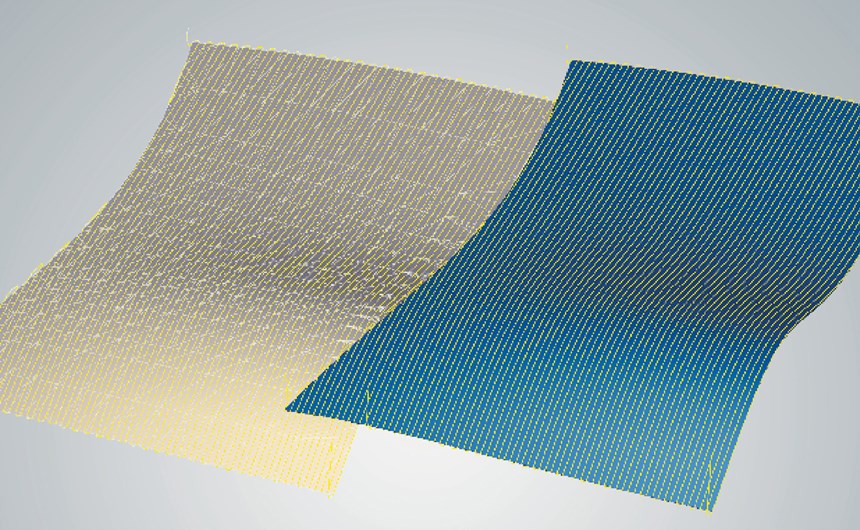

The five-axis prismatic fillet finishing function in the software enables the geometry and automatic inclination of barrel cutters to be applied similarly to high feed cutters, using a plunging and pulling movement at high feed rates. Performance is attainable using conical barrel cutters, according to the company. Ball or bull nose end mills can be utilized with this milling strategy.

The profile milling technique in the software has an option that is said to improve the quality of machined surfaces. The company has implemented techniques in this software update for machining directly to the model surface, different from the traditional mesh surface approach to CAM processing. The updated thread milling module supports a large number of thread milling types while simplifying selection and milling direction options, according to the company. Also, recalculation cycles are no longer required with this software update when changes are made to the job. In addition, for improved tool management users can expand the tool database, enabling the ability to store order numbers, pricing and tool life details.

HyperCAD-S , which is said to be specially optimized for CAM requirements, includes polyline management, enabling CAD functions such as lengthening or shortening to be applied by the element type. Polylines can also be machined similar to other elements, with trim, join, orient or select.

Related Content

-

Siemens CNC Control Enhances Shopfloor Productivity with Robot Integration

Siemens Digital Industries' Sinumerik 828 CNC seamlessly integrates with KUKA robots for cost-effective part handling and automation in job shops.

-

Prime Technical Services Monitoring Solutions Support Lights-Out Manufacturing

PMTS 2025: Prime Technical Services Inc. showcases CNC tool monitoring and process control from Caron Engineering, as well as smart manufacturing solutions from Blum-Novotest Inc.

-

Precision Machining Technology Review: April 2025

Production Machining’s April 2025 technology showcase includes some of the latest technology from Sumitomo, Hurco, Supertec, SMW Autoblok, SW North America and Tungaloy.