Steelhead’s Customizable Software Improves Shop Productivity

PMTS 2023: The software has an all-in-one dashboard that enables all employees to access targeted information applicable to their responsibilities.

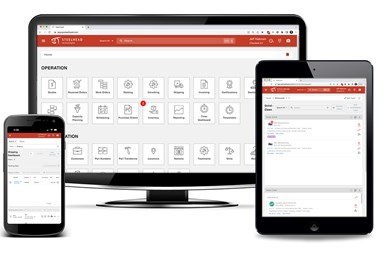

Steelhead Technologies says it offers an ultramodern software solution for managing job shops with a highly customizable, cloud-based platform that can be precisely tailored to drive data-based management. The software features an all-in-one dashboard that enables employees to access targeted information applicable to their responsibilities.

The job shop software is designed specifically for the process manufacturing industry. Created to manage production in dynamic environments, the system’s intuitive design enables operators to be trained in minutes and customers can launch the technology at their job shop within weeks for a simple, yet extremely effective, digital transformation.

The software is used in manufacturing to improve the process, profitability, productivity and quality of an entire plant by eliminating wasted time in order processing, administrative tasks and paper workflows. As job shops are looking for a way to process more parts, faster, Steelhead software can significantly save time to free up operators to get more done, reduce lead times and ultimately boost profitability, increasing the overall value of the business.

User can create an accurate quote in seconds with customized pricing algorithms. The software can also harness full production visibility and data to uncover job cost data to optimize productivity and boost profits by up to 35%. The software enables users to send quotes, add work orders, include product recipes, track the movement of parts, send packing slips and invoices, train operators, automatically generate reports and reprioritize jobs all with the tap of a finger.

Related Content

-

Approach PMTS 2025 With a ‘Process’ Mindset

High-volume machining operations are more apt to think about the entire process of producing parts beyond the machine tools themselves. All such technology is presented at the 2025 edition of the Precision Machining Technology Show.

-

Schütte Grinding Machine Minimizes Cycle Times

PMTS 2025: The Schütte 335Linear five-axis all-linear precision universal grinding machine is designed for high-precision tool and cutter grinding.

-

5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.