Heat-resistant superalloys (HRSA) are highly dense metals composed of nickel (Ni), iron-nickel (Fe2Ni) — including nickel steel or stainless steel — cobalt (Co) and chromium (Cr) that can be used at temperatures up to 70% of their melting points, ranging from 1,900°F (1,050°C) to 2,200°F (1,200°C). Although HRSA resistance to corrosion and heat make them well suited for applications in aerospace, defense, general machining, marine, medical/biomedical, oil and gas, petrochemical and power generation industries, they generally have poor machinability characteristics.

This is due to those materials’ high hot hardness and strength, high dynamic shear strength, low thermal conductivity, austenitic (NiCr or NiFeCr) matrix, hardening during machining, abrasiveness and common formation of built-up edge on an insert. In continuous cuts such as turning, manufacturers often use ceramic inserts for roughing due to their hardness because they can typically cut faster than carbide inserts. However, ceramic inserts do not have the toughness required to handle corners or interrupted cuts, which is far from ideal when used to rough-machine HRSA.

Heat-resistant superalloys (HRSA) are highly dense metals that have poor machinability characteristics, making rough-turning operations challenging. (Photo Credits: Palbit SA)

To provide manufacturers with a more efficient way to machine HRSA, Palbit SA (a Portugal-based, vertically integrated manufacturer of carbide tooling) developed DOMX heavy roughing inserts. Pilot Precision Products, of South Deerfield, Massachusetts, became the exclusive U.S. master importer of Palbit carbide cutting tools in 2022.

The letters D, O, M and X are taken from the ISO insert designation chart. D corresponds to the insert’s shape (rhombic 55 degrees); O is the clearance (relief angle) designation which, in this instance is “other” to signify a new design not reflected in letters A-G, N and P; M denotes the tolerance class (nose height, inscribed circle and thickness in millimeters); and X symbolizes the insert’s geometry (special design).

DOMX inserts are made of solid carbide, come in a single size #4 size, are PVD coated and well suited for medium-to-rough turning of HRSA because they combine high hardness with high heat-resistance properties. A DOMX insert features four positive cutting edges on a double-sided negative insert and can reduce cycle times to varying degrees while increasing tool life by as much as 140%.

DOMX inserts must be used with Palbit SA’s proprietary right- or left-hand holders. The inserts are made of solid carbide, come in a single size and feature a PVD coating.

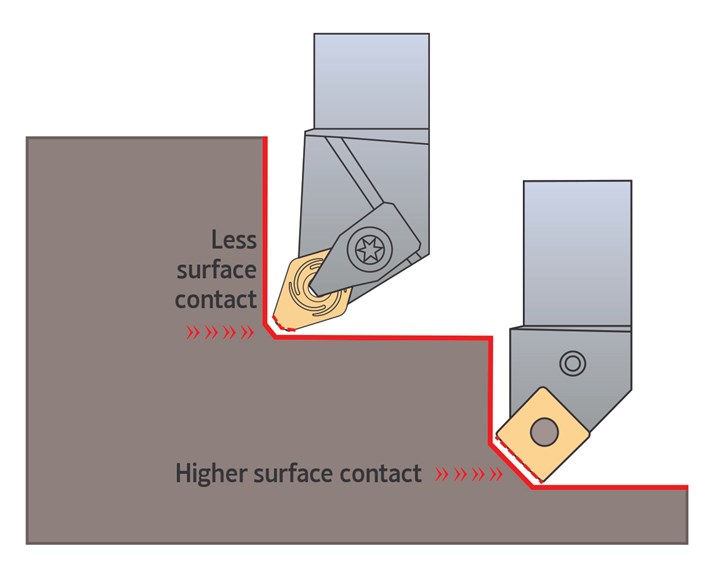

The chip breaker geometry enables DOMX inserts to provide the same impact as a high feed insert but with a lower amount of surface contact to minimize head and cutting pressure. As a result of that design feature, DOMX can take a heavy cut and generate low amounts of heat in the cut, enabling the insert and the workpiece to retain their respective shapes and properties.

The inserts give shops the option of using high-speed, high-feed roughing in a single-pass operation.

DOMX approaches into corners faster than alternative tooling. It also finishes the cut without failing — as opposed to what can happen with ceramic inserts when machining HRSA because those inserts lack toughness and get overheated when used at variable speeds.

According to Palbit SA, DOMX inserts can approach faster than alternative tooling and finishes the cut without failing as can happen with ceramic inserts when machining HRSA.

In short, DOMX inserts gives shops the option of using high-speed, high-feed roughing in a single-pass operation. Specifically, they enable a 45-degree insert lead angle to produce a higher depth-of-cut in rough or medium turning applications. They can be used for facing, external or internal turning, case machining and ring machining while offering cycle time reduction, tool life improvement and stability in the roughing process at a lower cost than ceramic inserts.

Tool Setup Tips

DOMX is a patented insert design and must be used with Palbit’s proprietary right- or left-hand holders. To achieve the optimal setup for an application, the lead angle should be as close as possible to 45 degrees based on the workpiece shape. By creating a 45-degree lead angle, tool life can be increased by 30% or more. A 45-degree lead angle also increases cutting force, improves rigidity and reduces deflection. Although chatter or tool deflection might occur, shops will still likely experience higher material removal rates and increased productivity.

Shops can determine the largest possible radius for dispersing the effects of cutting forces, reducing notch wear and decreasing the probability of insert breakage by performing calculations on one’s own or with assistance. With so many variables involved, an engineering conversation is likely to be necessary before deciding whether DOMX inserts are optimal for a given application.

Related Content

“Turning” the Tables: 10 Must-Read Articles to Sharpen Your Lathe Game

From complex Swiss-type lathes to turning basics, we’ve rounded up 10 turning articles for both beginners and advanced machinists.

Read MoreWhen a CNC Turn-Mill Doesn’t Turn

A shop in Big Sky Country uses a B-axis multitasking machine to produce complex, prismatic medical parts that require no turning complete from barstock.

Read MoreCraftsman Cribsheet No. 134: ISO Material Groups: Steel

How to interpret the machinability of various forms of steel.

Read MoreMetalworking Fluid Management and Best Practices

Cutting metal is a complex process involving many critical factors to be successful. Correctly applied metalworking fluids, including oils or coolant, is one of these critical factors.

Read MoreRead Next

Keeping Your Tool Cool From the Inside Out

Dual internal coolant channels in this parting off/grooving tool are said to provide greater cooling capability than external flood coolant delivery.

Read MoreTips to Make CNC Machining Tool Failure Predictable

Accurate prediction of tool life is key to establishing a controlled, repeatable and reliable CNC machining process.

Read More4 Strategies for Managing Chip Control

Having strategies in place for managing chips is an important part of protecting the production process, from tool life to product quality.

Read More