Collets Offer Quality Consistency

Quality consistency is a crucial characteristic to have for a shop to succeed. Producing such work for customers requires quality consistency inside the shop as well, including everything from shop management to the machines’ tooling and workholding.

Quality consistency is a crucial characteristic to have for a shop to succeed. Producing such work for customers requires quality consistency inside the shop as well, including everything from shop management to the machines’ tooling and workholding.

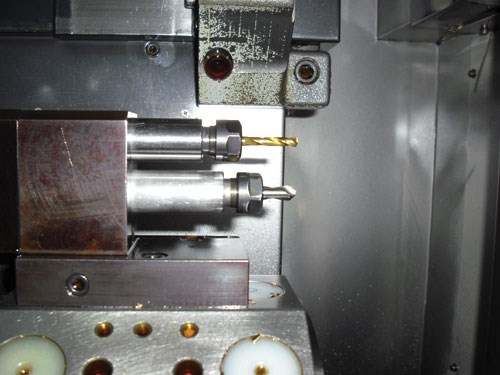

When you are a shop that produces tight tolerance, high accuracy custom parts, holding precision tolerances can be challenging. This is why Swiss Automation Inc. (Barrington, Ill.) recognized the importance of a quality collet when they began using Rego-Fix collets.

"You know what you are going to get every time," says Vanessa Malo, company spokesperson, Swiss Automation, speaking about Rego-Fix collets. "They are reliable, predictable and are problem-free."

Swiss Automation sells to industries such as medical, defense, aerospace, hydraulic, electronic and pneumatic. It thrives by having the most up to date and technologically advanced equipment and employing and retaining experienced, knowledgeable, creative people who are good listeners and teachers.

Producing accurate parts, which goes hand-in-hand with quality consistency, is beneficial to the company as well, especially when performing an operation such as micro-drilling. According to the company, these collets help achieve consistent accuracy for this tricky operation.

Product availability is another concern for the company. Quick delivery and easy access to distributors is a must. "Even if one tool company does not have the Rego-Fix collet we are looking for, another distributor will have it," Ms. Malo explains. "We never have to wait for the product, nor do we have

to substitute."

In the past, the company used Rego-Fix sealing disk collets. But when metallic sealed collets made their debut in the market in 2007, Swiss Automation made the switch. Deciding which type of collet to use comes down to a company’s personal preference, and Swiss Automation prefers the metallic sealed collets. "We’ve been using them ever since Rego-Fix came out with them, and they have made a big improvement for us," says shop foreman, Marc Moran.

After using both the sealing disk collets and the metallic sealed collets from Rego-Fix, the company has found quality consistency with both types of collets. Mr. Moran explains, "Both collet systems work well, but when it is time to change the collet, the switch is so easy with the high pressure (metallic sealed) collet because it is all one part. With the sealed disk, the seal can be wiped out by coolant pressure." Because the collet replacement is so simple, it saves the operator time as well.

Ms. Malo adds, "They (the metallic sealed collets) are a good alternative to the sealing disks, as the sealing disks require more maintenance and parts."

"On the sealing disk system, which was out long before the metallic seal, we have a special nut and sealing disk that snaps into the nut that locks the coolant in," explains David McHenry, product manager, Rego-Fix. "With this system, you have a nut and then a disk, so you have two parts you have to keep track of." A special nut and disk must be purchased for each size.

With the metallic sealed system, however, the collet is all one piece. "The collet itself seals the coolant and does all the work as far as keeping the coolant going through the cutting tool," Mr. McHenry says. The downfall is that when using this system, you don’t have a full collet range. Other collets have about a 1-mm clamping range, but with this system, there is no clamping range or only a 0.5-mm range. "You end up needing more collets on hand to cover a clamping range," he adds.

Although the sealing disk system’s disadvantage is that it contains more parts and therefore, more maintenance, its advantages include the fact that standard collets can be used (special collets are not necessary), and a wider clamping range is available.

According to Mr. McHenry, the sealing disks also offer a higher cleanliness factor. By design, the seals are in front of the collet, which keeps the collet itself cleaner in the case of machining hard materials that produce very small chips such as brass and graphite, he explains. "The open slots in the collet are exposed and the chips may pack in those slots and call for more cleanup between tool changes," Mr. McHenry says. However, if you are cutting aluminum and steel, this isn’t a problem, he adds.

According to Mr. Moran, however, Swiss Automation machines many different types of metals, including hard materials, and it doesn’t have an issue with chip cleanup. "We don’t have to clean the collets because the coolant through keeps them clean," he explains.

By relying on Rego-Fix collets, Swiss Automation has held tight tolerances, which, in turn, results in quality consistency and high accuracy.

Related Content

SMW Autoblok Workholding System Streamlines Changeovers

The TMS-2G system enables the operator to change the chuck in minutes accurately and securely, making it versatile for diverse metalworking requirements.

Read MoreBar Feeder Designed with Swiss-Types in Mind

New technology enables this bar feeder to fully support the bar pusher and stock from inside the unit all the way to the spindle of a sliding headstock lathe.

Read MoreWhat’s the Right Bar Feeder for Your Machine Shop?

Machine shops likely have questions about what type of bar feeder makes most sense for their operational needs. One or more of these four might be floating around in your head.

Read MoreThe Workholding is the Hardest Part

Finding a way to fixture contoured marine propellors proved to be this shop’s biggest challenge in developing an effective automated machining and turning cell.

Read MoreRead Next

How To (Better) Make a Micrometer

How does an inspection equipment manufacturer organize its factory floor? Join us as we explore the continuous improvement strategies and culture shifts The L.S. Starrett Co. is implementing across the over 500,000 square feet of its Athol, Massachusetts, headquarters.

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read More