Remote Access and Monitoring Reduces Service Calls

By implementing this system on its CNC turning machines, the company, Monogram Aerospace Fasteners (MAF), reduced machine tool service calls by more than 25 percent, saving time and increasing productivity.

While at the IMTS 2012 trade show, a team of engineers came across a demonstration of a remote access, condition monitoring system from Siemens, decided they wanted it for their company and made it happen. By implementing this system on its CNC turning machines, the company, Monogram Aerospace Fasteners (MAF), reduced machine tool service calls by more than 25 percent, saving time and increasing productivity.

Recently, after MAF (Los Angeles, California) had purchased four new Eubama S6 CNC turning machines equipped with the Siemens Sinumerik 840D CNC, company personnel thought it was an appropriate time to invest in the ongoing condition monitoring system offered by Siemens that would substantially improve the predictive maintenance capabilities at the shop.

MAF manufactures blind bolts for aircraft assembly, temporary fasteners for fixturing and alignment as well as installation, finishing and removal tools. It is the maker of Visu-Lok, Composi-Lok, Radial-Lok and OSI-Bolt, brands well known in the aerospace industry.

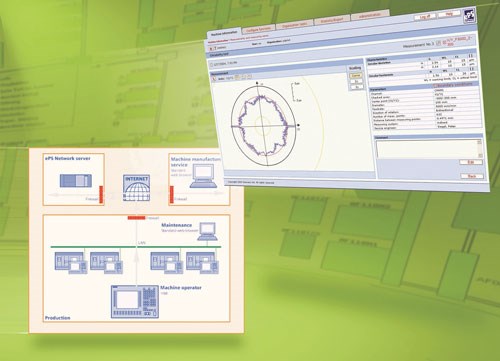

With no interruption in production, the electronic production services (ePS) protocol could be set up on each machine, monitoring every keystroke and machine action taken, storing them on a secure cloud server. According to Daniel Martinez from the Aerospace Center of Competence at Siemens, “MAF’s basic service contract would be extended by giving our service department the ability to look into the company’s Eubama machines on very short notice. In the end, Karl Haffner (MAF’s industrial technologist), convinced his management that the enhanced service and remote access capabilities of our ePS were a less costly investment, compared with the increase in service and inside maintenance needed.”

After a lengthy needs assessment by Valerie Biester, business developer for Siemens, and her team working with Mr. Haffner and other MAF personnel, it was determined the condition monitoring system would track five key conditions (or “triggers”) with SMS/email notification. Additionally, production part count would be plotted graphically, for easy access by the production team.

The five triggers included a maintenance task involving backups on each machine, part counts per shift, spindle temperature, alarm log and current status of each machine, plus a notification if the machine was in e-stop condition for more than 30 minutes.

Through ePS, all HMI action logs, machine data and CNC status data are captured in real time. A PLC trace enables the prior actions to be taken as a snapshot for instant analysis of alarms. Alerts generated by the system can take the form of text or email messages, both internally to the MAF personnel and externally to the Siemens technical support.

On the Siemens technical support side, engineer Brad Cornell says, “By accessing the Eubama machines at MAF with our ePS, we eliminated additional calls to identify part numbers and software versions. I could look into the error log, versions display and machine data instantly to get actual values. By utilizing ePS remote viewing, we minimized time spent on the diagnosis of a failure.”

With the remote access and condition monitoring services installation, setup and MAF operator training complete in less than one day, the impact on production was minimal and, according to Mr. Haffner, the improvements in the maintenance efficiencies have been substantial at his company.

As an example of the functionality of the system, MAF contacted a Siemens technical center regarding a fault on one of the turning centers with the condition monitoring system in place. The remote access session was initiated by the MAF operator directly on the machine’s CNC, and the technical support was able to see the alarm log directly on screen to diagnose that an on-site field service call was needed. However, prior to the use of ePS, this incident would likely have required three to four additional calls and as much as 300 percent more time to resolve.

Related Content

The Value of RFID Machine Operator Authentication

Can secure shopfloor employee authentication via radio frequency identification enable shops to optimize their data-driven manufacturing efforts?

Read MoreVideo: Using AR for Remote Machine Tool Troubleshooting

Augmented reality can enable service engineers to help machine shops identify and possibly remedy issues with their machines remotely, perhaps eliminating the time and cost of an on-site diagnostic and maintenance visit.

Read MoreBlueprints to Chips: CAD/CAM Tips and Tricks

This collection of articles delves into the latest CAD/CAM innovations, from AI-driven automation and optimized tool paths to the impact of digital twins and system requirements.

Read MorePiezoelectric Sensor Technology: Moving Toward more Efficient Machine Monitoring

A new system that uses simple and compact force or strain sensors, which can be integrated inside toolholders or mounted on surfaces such as spindle housings, can facilitate CNC machine monitoring.

Read MoreRead Next

Finding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreHow To (Better) Make a Micrometer

How does an inspection equipment manufacturer organize its factory floor? Join us as we explore the continuous improvement strategies and culture shifts The L.S. Starrett Co. is implementing across the over 500,000 square feet of its Athol, Massachusetts, headquarters.

Read More