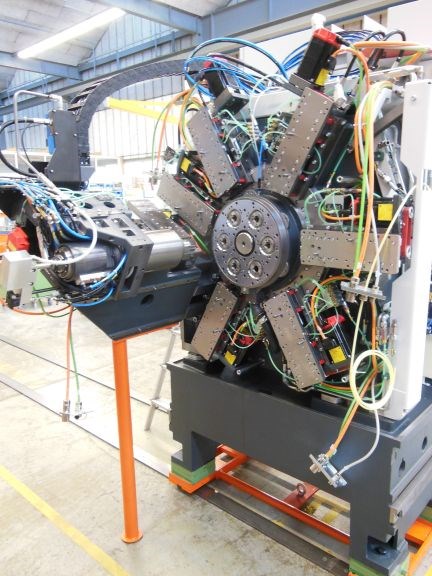

Sliding Headstock on Six Spindles

On my most recent trip to Europe, I visited the headquarters of Tornos in Moutier, Switzerland.

On my most recent trip to Europe, I visited the headquarters of Tornos in Moutier, Switzerland. The timing was good because we were in the process of wrapping up an article for our November issue about the company’s Cyklos surface finishing machine designed to give shops the ability to integrate electrochemical or chemical surface processing into their manufacturing lines. More about this machine can be found in the Tech Brief “Finishing Touch.”

As it turns out, the Cyklos is produced in a different facility than the one we toured. But I did get to see a number of other Tornos machines in various stages of production. The one that most caught my eye this time through was the MultiSwiss, a six-spindle CNC that provides sliding headstock capability on all six spindles. This machine was first introduced at last year’s EMO and was also displayed at IMTS in September.

Designed for parts less than 14-mm diameter (40-mm length), it features 14 linear axes, seven C axes and room for as many as 18 tools (three per position). Quick-change flexibility, wide-open access to the machining area, and the use of standard tooling contribute to its productivity advantages.

The machine is the result of 4 years of research and development in an effort to bridge the gap between single-spindle and multi-spindle lathes. More details can be found in the article “A Multi-Spindle and Swiss Combination.”

Related Content

-

Precision Machining Technology Review: June 2025

Production Machining’s June 2025 technology showcase includes some of the latest technology from Kaiser Tool Co., Tungaloy, Renishaw, Mazak, Oasis Inspection Systems and Star Cutter Co.

-

Precision Machining Technology Review: February 2025

Production Machining’s February 2025 technology showcase includes some of the latest technology from Marubeni Citizren-Cincom, Murata Machinery USA, Mazak, Star CNC, Grob Systems and Schütte.

-

Striving for Faster Changeovers for Multispindles

A multispindle platform designed to combine the high production speed of a cam-driven machine with the precision and repeatability of CNC also includes technology to speed set ups for new jobs.