Carmex Inserts Designed for Challenging Machining Applications

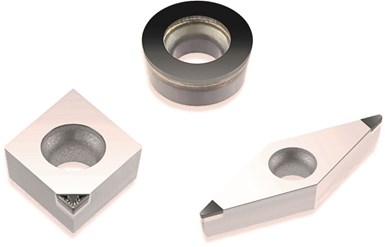

Carmex diamond PCD, CVD-T and PCBN turning inserts designed to increase efficiency and productivity for difficult materials.

Carmex Precision Tools’ diamond turning inserts are designed to deliver higher productivity and greater efficiency in machining non-ferrous and hard materials faster and more effectively than grinding or ceramics. According to the company, the diamond PCD inserts excel in the machining of nonferrous materials, including high-silicon aluminum, copper and brass alloys, magnesium, carbon fiber-reinforced plastics and composites.

Similarly, the CVD is designed for machining aluminum and magnesium alloys, high-silicon aluminum, precious metal alloys, plastics with abrasive fillers, tungsten carbide, and ceramic green compacts. The company says an advanced chip breaker reduces heat generation and energy consumption.

The diamond PCBN inserts are said to deliver high-precision performance and excellent surface finish in materials including hardened and heat-treated steels up to 72 HRc, high-speed steel (HSS), high alloyed steels hardened to 45 HRc and higher, super nickel-based alloys, grey cast iron, ductile and graphite.

The diamond inserts are available in both one and two cutting edge configurations to deliver both higher performance and longer tool life.

Related Content

-

The Promise of Additive Manufacturing for Paul Horn GmbH

Additive manufacturing offers various benefits for cutting tool manufacturers such as reduced tool weight and the creation of complex internal coolant channels that cannot be produced via traditional CNC machining methods. Here is how it currently plays out at one such German company.

-

Addressing Micro-Boring Challenges

This boring bar/tool holding system for Swiss-type lathes is said to offer high rigidity and positioning repeatability. In addition, the boring bars can be changed out using no hand tools.

-

Deep-Hole Advice Using Replaceable-Insert Drills

A cautious approach, modern thinking, offline presetting and attention to coolant and chips unlock the potential of the latest replaceable-insert drills for deep-holemaking applications.