An increasing number of cutting tool manufacturers are researching and testing the advantages of hybrid tools. These are tools which feature a traditional solid, tapered toolholder created by CNC machining combined with a more complex tool body produced via additive manufacturing.

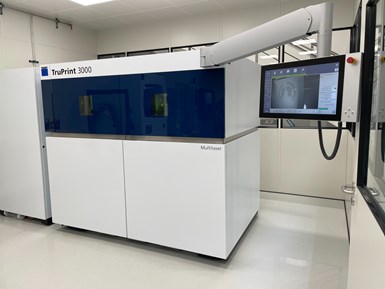

At the 2025 Horn Technology Days event held at Paul Horn GmbH’s headquarters in Tübingen, Germany, I learned more about how the cutting tool manufacturer is currently using its Trumpf TruPrint 3000 twin-fiber laser machine for these and other applications, and how the use of this technology might increase in the years to come. This is explained in the form of the following Q&A I had with Dr. Matthias Luik, head of research and development at Paul Horn.

DK: What specific features of the Trumpf machine made it attractive for your company’s needs?

ML: The Trumpf TruPrint 3000 is robust and stable machine which can be successfully use for industrial 3D printing. It features twin 500-watt fiber lasers and a 300-mm-diameter by 400-mm height build envelope while enabling external powder management.

The Trumpf TruPrint 3000 at Paul Horn’s headquarters in Tübingen, Germany, features twin 500-watt fiber lasers and a 300-mm-diameter by 400-mm height build envelope. Source (all photos): PM

The machine is equipped with one build cylinder and two supply powder cylinders which can be quickly exchangeable. This feature make it well suited for multi-material applications because it eases material changeover while avoiding powder cross-contamination. The separate sets of build cylinder and two supply cylinders can be used for each dedicated powder material and, in this scenario, there is no need to clean them.

We selected the TruPrint 3000 based on performed benchmark testing. The 3D-printed parts that came off the machine demonstrated the best quality (surface roughness, part density and so on) among other machines available on the market at that time in 2022.

DK: Is the hybrid tool concept a big area of research for Paul Horn?

ML: The hybrid tool concept is always in focus for us, especially for large tools, because it makes additive technology more cost-effective and it can compete with conventional machining in terms of price. Additive manufacturing makes a lot of sense for the area of the tool that requires a special and complex structure. Conversely, the simple, solid area of the tool, such as the toolholder, can be easily and much more inexpensively produced via conventional machining. Therefore, it makes no sense to 3D print the entire tool because the hybrid concept offers a massive cost savings.

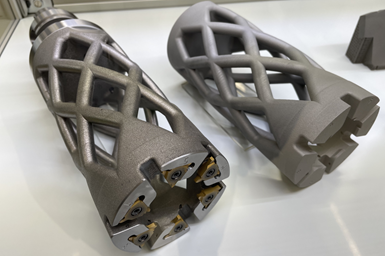

This bell-shaped, hybrid milling tool includes very complex, contoured internal coolant channels which can be fabricated only via additive technology to more accurately deliver coolant to the point of the cut.

DK: What are the key specifications relative to the hybrid tool shown in the photo to the left that was on display at Technology Days?

ML: We printed the body of this bell-shaped milling tool from 1.2709 tool steel. For this tool, the full build envelope consisted of six tool bodies and the total build time was approximately 61.5 hours at a layer thickness of 60 microns.

The tool includes very complex, contoured internal coolant channels which can be fabricated only via additive technology to more accurately deliver coolant to the point of the cut for optimal cooling and chip evacuation. In addition, this process also reduced overall tool weight. An advantage of this is less strain on a machine tool’s spindle and quicker tool acceleration and deceleration.

DK: What are the advantages of additive manufacturing in terms of internal coolant channels for toolholders?

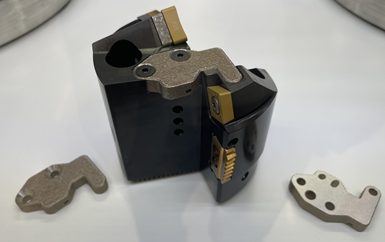

For this 3D-printed toolholder model, a single cooling channel at the base splits into two channels that lead directly to the two cutting inserts.

ML: At Technology Days, we displayed Horn IK Graf toolholders printed from 1.2709 tool steel with complex countered internal coolant channels. These types of the coolant channels can only be fabricated by additive manufacturing. The process offers a unique way to bring precisely the right volume of coolant directly to the cutting edge of the applied inserts which are used in this toolholder model.

A single cooling channel at the toolholder base splits into two channels that lead directly to the two cutting inserts. Additionally, one of these channels is divided into two additional outlet channels at the “twin outlet,” enabling cooling of the cutting inserts. These cooling channels are located just below the tool contour surface layer where the material area available for the channel is very limited.

The 3D-printed cassette for a tool for oil-field applications provides the proper volume of coolant to the front of the tool.

DK: Were there any other examples on display at Technology Days of tooling components with complex internal coolant passages?

ML: Another example is a printed coolant attachment for a new cassette tool for oil field applications. This type of complex contoured internal coolant can be only fabricated via additive manufacturing technology. This cassette provides the proper volume of coolant to the front of the tool and cools the most exposed cutting inserts to avoid fast insert wear while optimizing the machining process.

DK: Do you believe there will be increasing use of the TruPrint 3000 for creating special tools for customers in the future?

ML: Currently, the Horn Additive Manufacturing Competence Center together with our R&D department is developing new 3D-printed tool concepts based on customer needs. All new designs and solutions are internally proven by our testing department, and after successfully results, we can perform these tests at the customer’s facility to get feedback as to how they work in practice.

There are so many unexplored solutions which can be created via additive manufacturing, and we are still in the early stages of implementing the 3D printing technology in our tool manufacturing applications. Obviously, our use of additive manufacturing will increase as we discover new benefits of the process.

The Horn Additive Manufacturing Competence Center also is a service bureau providing 3D-printed parts to customers for non-cutting-tool applications such as titanium tuners and other components for EBG-Instruments guitars.

As a result, in order to be flexible in production and ensure fast delivery of printed tools or parts to customers, it will be necessary to add 3D printing capacity. And if each subsequent machine is dedicated to a specific material, this will speed production because changing the powder will no longer be necessary.

Additionally, additive manufacturing will enable us to support our internal tool production processes such as custom printed nozzles for our CNC grinding machines. We can also quickly print and deliver spare parts to our maintenance department upon request. Sometimes spare parts are not available, so we can significantly reduce machine downtime by printing those parts. And, in the process, we can still structurally optimize printed parts and better adapt them to our production needs and applications.

The market for 3D printing parts and tooling solutions will grow, and we have to run our own printing production process to meet specific customer orders on demand. We also offer one-source, end-to-end expertise from drawing to finished part.

As a service bureau, we can print parts for our customers from standard materials such as aluminum (AlSi10Mg), stainless steel (316L/1.4404), tool steel (1.2709) and titanium alloy (Ti6Al4V). Other materials are available on request.

Parts can be delivered in raw state directly after printing, but we can also offer comprehensive machining based on our deep manufacturing expertise and own cutting tools. We also offer heat treatment processes after 3D printing as well as sandblasting or tumbling surface finishing processes depending on the needs and requirements regarding surface quality. That way, customers receive a completed part requiring no additional machining or postprocess operations.

Related Content

Replaceable-Insert Spade Drill Basics, Advantages

Although solid carbide and indexable-insert drills have their place in a machine shop, replaceable-insert spade drills offer specific advantages for various holemaking operations on machining centers and lathes.

Read MoreDeep-Hole Advice Using Replaceable-Insert Drills

A cautious approach, modern thinking, offline presetting and attention to coolant and chips unlock the potential of the latest replaceable-insert drills for deep-holemaking applications.

Read MoreTaking a Calculated Approach to Thread Rolling

Thread rolling operations for Swiss-type lathes, multi-spindles and other turning equipment can be enhanced using online calculators to determine optimal process parameters.

Read MorePrecision-Driven Performance

Superion solid carbide tools for Swiss applications.

Read MoreRead Next

Finding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreHow To (Better) Make a Micrometer

How does an inspection equipment manufacturer organize its factory floor? Join us as we explore the continuous improvement strategies and culture shifts The L.S. Starrett Co. is implementing across the over 500,000 square feet of its Athol, Massachusetts, headquarters.

Read More