Datanomix Automated Production Intelligence Platform for ProShop ERP Software

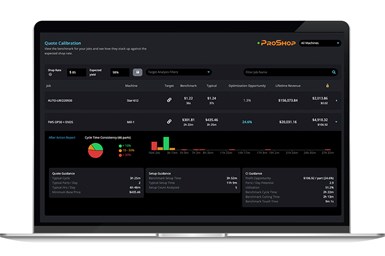

PMTS 2023: Automated Job Costing analytics compare ProShop ERP target cycle times to actual process performance in the Datanomix Automated Production Intelligence Platform.

Automated Job Costing analytics compare ProShop ERP target cycle times to actual process performance in the Datanomix Automated Production Intelligence Platform. This means machine shops are armed with a full list of jobs to focus on in order to find more margin. Users configure ProShop credentials, and the production platform does the rest, according to Datanomix.

The integration automatically matches part numbers in the platform to those from the ERP system and extracts specific target takt times. When compared to actual machine performance in the platform, the variance to standard is represented in terms of button-to-button time, cutting time and touch time, and summarized with the letter grade score of A+ to C-, making it obvious which jobs are underperforming.

ProShop targets are also integrated into the Datanomix Quote Calibration Report to quickly help identify long-term opportunities for margin improvement based on variance to cycle time standards.

Through two-way integration, the platform benchmarks and actuals are fed back into the ERP system so users can make more informed and accurate estimates based on real data.

Preloaded filters show users part numbers that beat ERP targets and are making more profit than anticipated; part numbers that did not beat ERP targets and are not making a profit; part numbers that are beating targets, but could be making even more money; part numbers that are losing on average compared to targets, but could be winning because Datanomix has seen users run the job well enough to turn it into a winner, the company says.

Related Content

-

T. J. Davies Retention Knobs Feature Corrosion Resistance

PMTS 2025: The company’s retention knobs are magnetic particle tested and then pull tested to 2.5 times the pulling force of the drawbar it is designed for.

-

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

-

Schwanog Custom Form Milling Tools Produce Complex Profiles, Contours

PMTS 2025: Schwanog’s custom form milling tools are designed to boost productivity and precision, with solutions individually manufactured according to customer drawings.