Emag Twin Spindle Lowers Gear Machining Costs

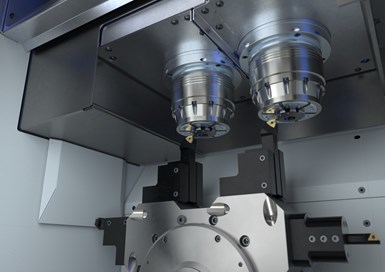

The VL 1 Twin-spindle pick-up turning machine simultaneously machines two identical bevel gears at high speed within the same machining area.

Emag’s VL 1 inverted-vertical, twin-spindle turning machine simultaneously machines two identical bevel gears at high speed within the same machining area. Combined with a robot cell and swivel table that can easily load the machine, it can bring the cycle time for machining bevel gears down to 4.5 seconds, which can drastically lower production costs. The machine is designed to manage large quantities cost-efficiently, quickly and free of defects. According to the company, the machine is well-suited for soft and hard machining of a wide variety of bevel gears up to 75 mm in diameter (3"). It features two pick-up spindles (9.9 kW/136 Nm at 40% duty cycle) that are used to machine two identical bevel gears in parallel. The two spindles load and unload the machining area in just five to six seconds.

The next machining steps are then performed successively and in a single clamping operation with a total cycle time of about 25 to 40 seconds (depending on type and size of part). The average chip-to-chip time is just under six seconds. A special clamping solution reproduces the negative image of the component’s gearing and holds it firmly in place. Additionally, the VL 1 Twin is able to drill into solid material, which is how the bevel gear’s center bore is produced. The machine is designed for fast production and high output quantities, while significantly reducing the price per spindle with rigorous cost controls — contributing to low unit costs.

Related Content

-

Automation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

-

Does a Scanning Probe Make Sense on a Swiss-Type?

Swiss-types have limited tooling capacity, but there can be advantages to giving up some of that capacity to take advantage of a touch probe — in fact, a scanning probe — to enable in-process part measurements.

-

Planning for Growth Amid Uncertainty

Six strategies to maximize a company’s success amid unpredictability.